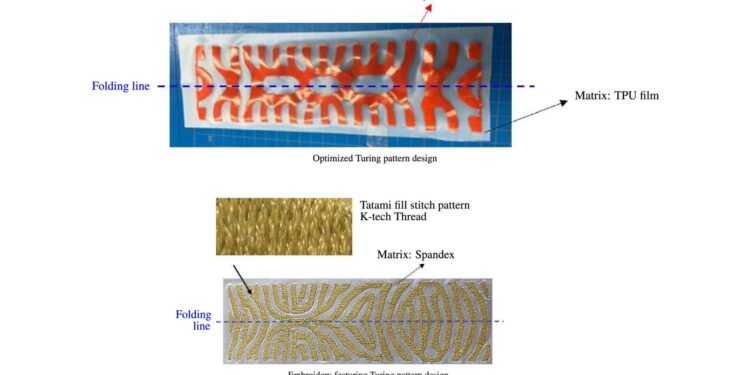

Top: Optimized heat-sealed Turing pattern design. Bottom: optimized embroidered Turing pattern. Credit: Masato Tanaka et al/Scientific reports. DOI: 10.1038/s41598-024-69450-z.

According to a recent study by Scientific reportsTuring models can be used to develop a new method for designing and producing fabric-based soft pneumatic actuators (FSPA).

Fabric-based soft pneumatic actuators (FSPAs) are flexible, flexible devices that can deform or move when pressure is placed on them. They work by inflating or deflating, which causes the fabric to fold, stretch or twist.

Soft robotics often relies on FSPAs due to their crucial flexibility and adaptability. Unlike traditional rigid robotic parts, FSPAs can safely interact with humans and delicate objects.

Their flexible and lightweight nature makes FSPAs ideal for applications such as wearable devices, adaptive shelters, robotic grippers and assistive devices. Their value lies in their low cost, security and flexibility.

However, the design and development of FSPAs is a real challenge. The challenge was met by the research team through automation of the process.

The team consisted of Dr. Masato Tanaka and Dr. Tsuyoshi Nomura from Toyota Central R&D Labs., Inc. in Japan and Dr. Yuyang Song from Toyota Motor Engineering & Manufacturing North America, Inc. in the United States.

Phys.org spoke with the researchers who shared their motivation for pursuing this research.

“The motivation behind this research stems from the recognized need in the soft robotics community for pneumatic actuators capable of performing controlled movements using simple mechanisms without relying on specialized materials or technologies,” said Dr. Tanaka.

Turing models

“Our goal was to develop simple, inexpensive FSPAs capable of transforming shape. We specifically focused on integrating Alan Turing’s theory of morphogenesis, known as Turing models, into the process. design of these surface textures,” said Dr. Nomura.

Alan Turing presented his theory of morphogenesis in 1952, describing how natural patterns (stripes, spirals, etc.) can arise from a uniformly distributed state.

“Inspired by the work of Alan Turing in which the Turing model can be derived from isotropic reaction-diffusion equations, we used a gradient-based orientation optimization method to design the surface membrane of FSPAs ” said Dr. Song.

Turing models arise from systems with reaction and diffusion components. The main idea is that we have two interacting substances, one of which promotes the promotion of both and the second suppresses or inhibits the first.

The result of this feedback loop is the formation of stable, repeating patterns, or Turing patterns, like the stripes seen on zebras and tigers.

Trial and error

The biggest challenge when designing FSPA is the need for trial and error to find the right material.

“Traditional pneumatic structures typically use isotropic materials with specific geometric features, such as seam lines, to achieve shape transformation,” explained Dr. Tanaka.

Soft isotropic materials, known for their uniform properties, are commonly used in traditional FSPAs. This ensures that the material swells or bends evenly when pressure is applied.

However, designing and manufacturing a material that deforms in a controlled and predictable manner requires trial and error and can be time consuming. The research team’s goal was to circumvent these limitations through process automation and optimization, which would result in more advanced and controlled movements in software robotic applications.

“We use a gradient-based orientation optimization method to design the surface membrane of these structures. This method assumes the use of anisotropic materials on the membranes, where the orientation can vary freely, making manufacturing such structures a significant challenge,” said Dr. Song.

“Our research addresses this challenge by using Turing models to bridge the gap between material orientation-based optimization design and 3D printing,” added Dr. Nomura.

Process automation

FSPAs are made of the material, which is the fabric used to construct the actuator and the actuator, which performs movement in response to pressure.

The first step in their method was to optimize the material orientation, that is, how the fibers of the flexible fabric are arranged on the surface of the actuator.

For this, they used the nonlinear finite element method. After optimization, the orientation layout was converted into particular patterns on the material.

These specific models were generated from a mathematical model of anisotropic reaction-diffusion systems used by the researchers. This pattern fills the entire surface and ensures that the material deforms in the desired way.

“By solving these equations and incorporating information about the optimized anisotropy distribution of the material, we generated anisotropic Turing pattern textures corresponding to the anisotropy of the original material,” explained Dr. Tanaka.

To make FSPA, researchers explored two methods: iron-on and embroidery.

In heat bonding, a stiff fabric such as Dyneema is laser cut into the required Turing pattern and then bonded to a softer fabric such as TPU film using a heat press. In contrast, the embroidery technique embeds the Turing pattern in a soft fabric with a stiff thread, resulting in areas of different stiffness that allow controlled movement.

“These demonstrated manufacturing methods provide scalable and cost-effective production opportunities for these advanced actuators,” explained Dr. Song.

Compare with the classics

The research team compared their designs to classical simple designs, with their Turing model designs showing comparable and better performance.

For C-shaped designs, the Turing model was found to be more effective than conventional designs, reducing the distance between actuator edges by approximately 10%.

For twisting motions, Turing models work similarly to classical models. However, S-shaped folding is traditionally difficult to achieve.

“Our method can achieve any movement with a simple pneumatic input by designing the textural pattern printed on the membrane using our optimization approach,” said Dr. Nomura.

According to the research team, future research could consider integrating Turing model designs with advanced materials such as shape memory or electroactive polymers, to develop actuators with improved dynamics.

The researchers also plan to explore scaling manufacturing techniques to accommodate mass production and larger actuators, possibly using approaches such as 3D printing with flexible materials or automated weaving to improve both efficiency and precision.

More information:

Masato Tanaka et al, Fabric soft pneumatic actuators with programmable turing pattern textures, Scientific reports (2024). DOI: 10.1038/s41598-024-69450-z

© 2024 Science X Network

Quote: Using Turing models to improve soft pneumatic technology (September 28, 2024) retrieved September 29, 2024 from

This document is subject to copyright. Except for fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.