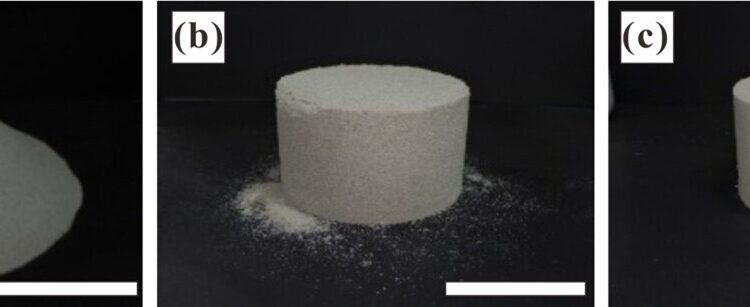

Sand columns with different proportions of sticky grains form and settle (stickier grains from (a) to (c)). Columns hold their shape better with stickier grains. Credit: Tokyo Metropolitan University

Scientists from Tokyo Metropolitan University studied the strength and toughness of sand columns made from a mixture of sticky and non-sticky grains. They discovered the mechanism behind how strength changes when grains are mixed in different proportions, and how mixing can help keep the column more resilient to deformation. The non-sticky grains are also easily replaceable by other materials, allowing the design of a stronger, more resistant and more functional material.

Granular material consists of a large number of small grains, such as sand and powders. These grains can be made to adhere to each other, thus producing solid materials such as concrete. But strength isn’t everything. Solid materials can be brittle and crack easily when deformed. Scientifically designing materials that are not only stronger, but also more resilient, continues to be a challenge for materials scientists.

A team from Tokyo Metropolitan University led by Professor Rei Kurita studied the mechanical properties of sand columns, a simple but powerful model for granular matter. Instead of focusing on grains that all stick together, they studied mixtures of non-sticky normal sand and “kinetic” sand, grains coated in silicone oil that can stick to each other. The research is published in the journal Physics of communications.

Although the mechanics of “attractive grains” are relatively well understood, this cannot be said for materials where adhesiveness only appears in a subset of grains.

(a) Deformation of sand columns under different loads. (b) Distribution of the number of local connections between sticky grains in columns under different loads. (c) Proportion of newly formed (red) and broken (blue) bonds between sticky grains. Credit: Tokyo Metropolitan University

When they made columns with different proportions of sticky grains, they found that the strength of the column, characterized by its degree of deformation when subjected to load, exhibits a characteristic gradual change.

When the proportion of sticky sand reaches 60%, the resistance suddenly changes to a higher value. Stickier sand does not cause additional increases.

Through computer simulations of a similar setup, they discovered that this was exactly when the sticky grains formed a rigid network that extended across the sample. These should be distinguished from sticky grains that simply connect across the sample; sticky grain lines, for example, can easily become distorted when the ends are pushed together. Only when there are enough connections between grains can the sticky grains support weight.

-

(a) Configuration diagram used to test column strength. (b) Stress in the column as a function of the proportion by which it is deformed. Alpha is the proportion of sticky grains. (c) Young’s modulus (stiffness) of columns with different proportions of sticky grains. Credit: Tokyo Metropolitan University

-

Columns with low (a) or high (b) proportions of sticky grains in a computer simulation. Different colors correspond to different rigid clusters, colored according to cluster size. Note how a single cluster covers the entire box in (b). (c) Stiffness of columns with different proportions of sticky grains (alpha) in simulation. Credit: Tokyo Metropolitan University

However, unlike typical strong materials, these partially bonded columns exhibit unique behavior when subjected to greater loads. When the column deforms, it does not crack; on the contrary, they change shape: the connections between the sticky grains are not simply destroyed but are able to reorganize and reform. This makes the columns not only strong, but also resistant.

The team notes that since more than 60% of the sticky grains do not change the strength, the remaining 40% can be easily replaced with any other material, for example one with antibacterial properties. This counterintuitive design feature paves the way for composite materials that are not only stronger and more durable, but also functional.

More information:

Honoka Fujio et al, Mechanisms of gel-like durability and deformability in wet granular systems, Physics of communications (2024). DOI: 10.1038/s42005-023-01518-0

Provided by Tokyo Metropolitan University

Quote: To stick or not to stick? Mixed Sand Columns Illuminate Better Materials Design (January 29, 2024) retrieved January 29, 2024 from

This document is subject to copyright. Except for fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.