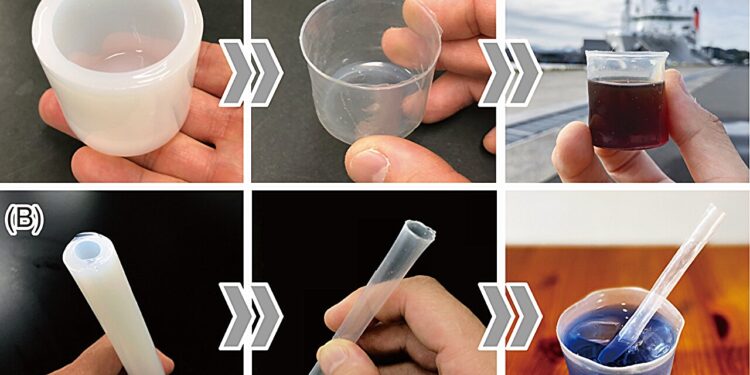

Formal nature of TPB. (A) Preparation diagram and appearance of TPBTEX in the shape of a cutting. The liquid TPBTEX was photographed within 30 minutes after the hot coffee is filled. (B) Preparation protocol and appearance of TPBTEX in the shape of a straw. TPBTEX in the shape of liquid was photographed within 30 minutes after the garnish of frozen butterfly pea tea. Credit: Scientific advances (2025). DOI: 10.1126 / SCIADV.ADS2426

A team of biomaterial engineers, specialists in environmental resources and industrial design researchers affiliated with a multitude of institutions across Japan has developed a biodegradable material which is clear and can contain boiling water – and it degrades in less than a year after having settled on the bottom of the ocean. Their work is published in the journal Scientific advances.

Previous research has shown that millions of tonnes of plastics are accumulating in the environment, including at the bottom of the ocean. For this reason, scientists have looked for better and biodegradable replacements. In this new effort, the research team has developed a paper material, clear and biodegradable which can withstand liquids for several hours, even those that have been heated, which allows them to replace plastic cups, straws and other daily objects.

The research team made the material starting with a standard cellulose hydrogel. After drying, the material was treated with an aqueous solution of lithium bromide which forced cellulose to solidify in the desired forms. Researchers note that end products could be as thin as plastic cup walls, or as thick as they are desired. They describe the material as TPB, a transparent 3D material made only cellulose.

Manufacturing of TPB. (A) TPB preparation diagram. “Powder” and “Textiles” refer respectively to the MCC and the textiles of unwanted cellulose. A millimeter thick TPB (the one with the thickness of 0.7 mm is illustrated with a smartphone (138 mm per 67 mm), and 1.5 mm is indicated in the insert) has been prepared by drying a centimeter cellulose hydrogel produced by the dissolution of cellulose and coagulation in an aqueous library solution. Credit: Scientific advances (2025). DOI: 10.1126 / SCIADV.ADS2426

Material tests have shown that it operated as well as standard consumption straws, without any sign of the collapse observed in paper straws that are used for a very long time. They also noted that cups made using the material disclosed shortly after three hours, adding a resin coating based on plants prevented them from fleeing.

The research team also tested the biodegradability of equipment in a marine environment. They made several leaves of the material and placed some in shallow waters, and others in very deep places. Previous research has shown that due to cold temperatures at great depths, materials take longer to deteriorate. They found that their new material deteriorated completely in less than 12 months in the deepest parts of the ocean.

Recyclability in a closed loop. (A) TPBTEX (“original”), TPBTEX recycled by the solvent, TPBTEX recycled in terms and TPBTEX recycled by the posed solvent ~ 10 cm in front of the sheets, shown with the fog values. Credit: Scientific advances (2025). DOI: 10.1126 / SCIADV.ADS2426

The final test involved how the equipment could be recycled. The research team found that it could be done quite easily, but that it became less transparent after being melted and reformed.

More information:

Noriyuki isobe et al, transparent cardboard fully accumulated with recyclability in closed loop and maritime biodegradability through the shallow depth, Scientific advances (2025). DOI: 10.1126 / SCIADV.ADS2426

© 2025 Science X Network

Quote: The transparent paper material can contain boiling water and degrade in the deep ocean in less than a year (2025, April 10) recovered on April 11, 2025 from

This document is subject to copyright. In addition to any fair program for private or research purposes, no part can be reproduced without written authorization. The content is provided only for information purposes.