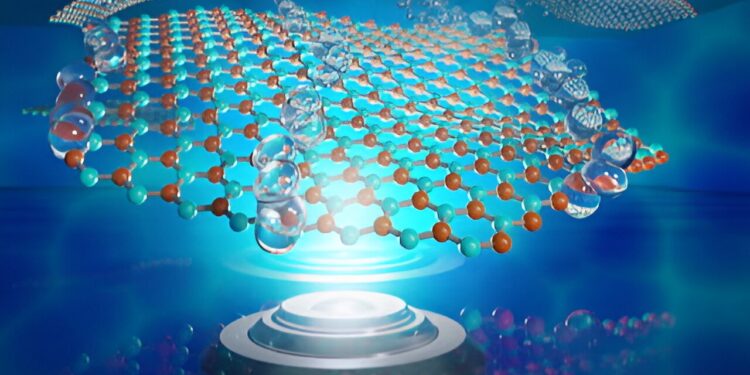

Credit: Mario Norton/Rice University

A team of Rice University researchers has mapped how particles of 2D materials move in a liquid – knowledge that could help scientists assemble macroscopic-scale materials with the same useful properties as their 2D counterparts.

“Two-dimensional nanomaterials are extremely thin sheet-like materials — only a few atoms thick,” said Utana Umezaki, a Rice graduate student and lead author of a study published in ACS Nano. “They behave very differently from the materials we are used to in daily life and can have very useful properties: they can withstand a lot of force, resist high temperatures, etc. To take advantage of these unique properties, we need to find ways to transform them into larger-scale materials like films and fibers.”

In order to retain their particular properties in bulk form, sheets of 2D materials must be properly aligned – a process that often occurs in the solution phase. The Rice researchers focused on graphene, composed of carbon atoms, and hexagonal boron nitride, a material similar in structure to graphene but composed of boron and nitrogen atoms.

“We were particularly interested in hexagonal boron nitride, sometimes called ‘white graphene’ and which, unlike graphene, does not conduct electricity but has high tensile strength and is chemically resistant,” said Angel Martí, professor of chemistry and bioengineering. , materials science and nanoengineering and chair of the Department of Chemistry at Rice. “One of the things we realized is that the diffusion of hexagonal boron nitride in solution was not very well understood.

The researchers used a fluorescent surfactant, that is, a luminous soap, to mark the nanomaterial samples and make their movement visible. Credit: Jeff Fitlow/Rice University

“In fact, when we looked at the literature, we found that the same was true for graphene. We could not find an account of diffusion dynamics at the single-molecule level for these materials , which motivated us to tackle this problem.”

The researchers used a fluorescent surfactant, that is, a luminous soap, to mark the nanomaterial samples and make their movement visible. Videos of this movement allowed researchers to trace the samples’ trajectories and determine the relationship between their size and the way they moved.

“From our observations, we discovered an interesting trend between the speed of their movement and their size,” Umezaki said. “We could express the trend with a relatively simple equation, which means we can mathematically predict the movement.”

Graphene was found to move more slowly in the liquid solution, likely due to the fact that its layers are thinner and more flexible than hexagonal boron nitride, resulting in more friction. The researchers believe the formula derived from the experiment could be used to describe how other 2D materials move in similar settings.

“Understanding how the diffusion of these materials works in a confined environment is important because, if we want to make fibers, for example, we extrude these materials through injectors or very thin dies,” Martí said. “So this is the first step in understanding how these materials start to assemble and behave when they’re in this confined environment.”

As one of the first studies investigating the hydrodynamics of 2D nanosheet materials, the research helps fill a gap in the field and could help overcome the challenges of manufacturing 2D materials.

“Our end goal in studying these building blocks is to be able to generate macroscopic materials,” Martí said.

Anatoly Kolomeisky, professor of chemistry and chemical and biomolecular engineering at Rice, and Matteo Pasquali, AJ Hartsook Professor of Chemical and Biomolecular Engineering and professor of chemistry, materials science, and nanoengineering, are corresponding authors of the study .

More information:

Utana Umezaki et al, Brownian diffusion of hexagonal boron nitride and graphene nanosheets in two dimensions, ACS Nano (2024). DOI: 10.1021/acsnano.3c11053

Provided by Rice University

Quote: Study reveals key dynamics of 2D nanomaterials for larger-scale production (February 1, 2024) retrieved February 1, 2024 from

This document is subject to copyright. Except for fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.