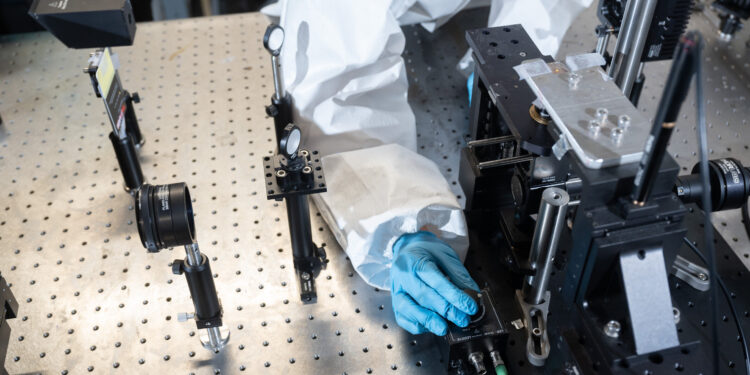

PhD student Jungho Choi controlling LED brightness levels on the SLP system. Credit: Georgia Institute of Technology

Researchers at the Georgia Institute of Technology have developed a light-based way to print nanometer-sized metal structures that is significantly faster and cheaper than any currently available technology. This is a scalable solution that could transform a scientific field long dependent on expensive and slow technologies. This breakthrough has the potential to bring new technologies out of the lab and into the world.

Technological advances in many fields rely on the ability to print nanometer-sized metal structures, a scale hundreds of times smaller than the width of a human hair. Sourabh Saha, assistant professor in the George W. Woodruff School of Mechanical Engineering, and Jungho Choi, a Ph.D. student in Saha’s laboratory, developed a technique for printing metal nanostructures 480 times faster and 35 times cheaper than the current conventional method.

Their research is published in the journal Advanced materials.

Printing metal at the nanoscale – a technique known as nanopatterning – can create unique structures with interesting functions. It is crucial for the development of many technologies, including electronic devices, solar energy conversion, sensors and other systems.

It is generally believed that high intensity light sources are required for nanoscale printing. But this type of tool, known as a femtosecond laser, can cost up to half a million dollars and is too expensive for most research labs and small businesses.

“As a scientific community, we do not have the capacity to produce enough of these nanomaterials quickly and inexpensively, and this is why promising technologies often remain limited to the laboratory and do not translate into real-world applications,” he said. Saha said. .

“The question we wanted to answer is: ‘Do we really need a high-intensity femtosecond laser to print at the nanoscale?’ » Our hypothesis was that we didn’t need this light source to achieve the type of print we wanted. »

They were looking for inexpensive, low-intensity light that could be focused in a manner similar to femtosecond lasers, and chose superluminescent light-emitting diodes (SLEDs) for their commercial availability. SLEDs emit light a billion times less intense than that of femtosecond lasers.

Saha and Choi decided to create an original projection-type printing technology, designing a system that converts digital images into optical images and displays them on a glass surface. The system works like digital projectors but produces sharper images. They exploited the unique properties of superluminescent light to generate perfectly focused images with minimal defects.

Size comparison between human hair (~100 micrometers thick) and the silver stamp printed on a glass slide. Credit: Georgia Institute of Technology

They then developed a transparent ink solution made from metallic salt and added other chemicals to ensure the liquid could absorb light. When light from their projection system hit the solution, it caused a chemical reaction that turned the salt solution into metal. The metal nanoparticles stick to the surface of the glass and the agglomeration of the metal particles creates the nanostructures. Since it is a type of projection printing, it can print an entire structure at once, rather than point by point, making it much faster.

After testing the technique, they discovered that nanoscale projection printing was possible even with low-intensity light, but only if the images were perfectly focused. Saha and Choi believe researchers can easily replicate their work using commercially available equipment. Unlike an expensive femtosecond laser, the type of SLED Saha and Choi use in their printer costs around $3,000.

“Right now, only top universities have access to these expensive technologies, and even then, they are located in shared facilities and are not always available,” Choi explained. “We want to democratize the capability of 3D printing at the nanoscale and we hope our research will open the door to greater access to this type of low-cost process.”

The researchers say their technique will be particularly useful to people working in electronics, optics and plasmonics, all of which require a variety of complex metal nanostructures.

-

Assistant Professor Sourabh Saha and Jungho Choi (PhD student) in front of their superluminescent light projection system at Georgia Tech. Credit: Georgia Institute of Technology

-

Scanning electron microscope image of the printed silver GT pattern. Credit: Georgia Institute of Technology

“I think the parameters of cost and speed have been largely underestimated in the scientific community that works on manufacturing small structures,” Saha said.

“In the real world, these parameters are important when it comes to translating discoveries from the laboratory to industry. Only when we have manufacturing techniques that take these parameters into account can we take full advantage of nanotechnology for the benefit of society.”

More information:

Jungho Choi et al, Scalable printing of metallic nanostructures using superluminescent light projection, Advanced materials (2023). DOI: 10.1002/adma.202308112

Provided by Georgia Institute of Technology

Quote: Researchers create a faster, cheaper way to print tiny metal structures with light (January 18, 2024) retrieved January 18, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.