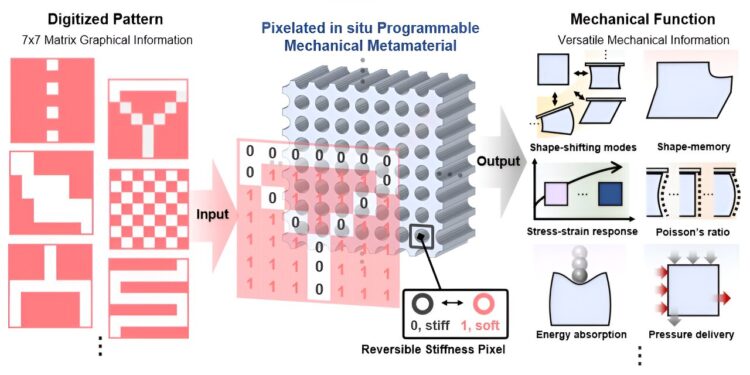

Figure 1. Concept and mechanism of PPMM for in situ programming of mechanical behaviors. The design concept of using digital models of binary numbers “0” and “1” to project versatile mechanical information. The binary information of a digital pixel is translated into discrete stiffness states of the corresponding mechanical pixel. A schematic gallery of several mechanical capabilities is presented, derived from various digitized model instructions. Credit: Advanced materials (2023). DOI: 10.1002/adma.202304302

Inspired by the remarkable adaptability observed in biological organisms like the octopus, a breakthrough has been made in the field of soft robotics. A research team led by Professor Jiyun Kim from the Department of Materials Science and Engineering at UNIST has successfully developed a codable multifunctional material capable of dynamically adjusting its shape and mechanical properties in real time.

This metamaterial exceeds the limitations of existing materials, opening new possibilities for applications in robotics and other areas requiring adaptability. The research is published in the journal Advanced materials.

Current software robots lack the level of adaptability demonstrated by their biological counterparts, primarily due to limited real-time tuning capability and a restricted reprogrammable space of properties and functionalities. To fill this gap, the research team introduced a new approach using graphical models of stiffness.

By independently switching digital binary rigidity states (soft or rigid) of individual constituent units within a simple auxetic structure featuring elliptical voids, the material achieves in situ and graded tunability across various mechanical qualities.

The digitally programmable material exhibits remarkable mechanical capabilities, including shape change and memory, stress-strain response, and Poisson’s ratio under compressive loading. Additionally, it demonstrates application-oriented features such as adjustable and reusable energy absorption and pressure distribution. This revolutionary material serves as a springboard toward the development of fully adaptive soft robots and intelligent interactive machines.

-

Figure 2. Shape-shifting and shape-memory abilities. a) Schematic illustration of various achievable shape change modes with simulation and experimental results. b–d) Quantitative programming of various shape change parameters: b) contractability, c) shear angle Φ and d) bending angle θ. Numerical models are explored and developed while preserving each reconfiguration mechanism to achieve stepwise adaptability. Compression load = 1 kg. Credit: Advanced materials (2023). DOI: 10.1002/adma.202304302

-

Figure 3. PPMM as an adaptive and reusable energy absorption material. Credit: Advanced materials (2023). DOI: 10.1002/adma.202304302

“We developed a metamaterial that can implement the desired features within minutes, without the need for additional hardware,” said Jun Kyu Choe, a researcher at the Seok and Park Integration Course and first author of the study. “This opens new possibilities for advanced adaptive materials and the future development of adaptive robots.”

The research team presented the material’s potential by demonstrating an “adaptive shock energy absorbing material”, which adjusts its properties in response to unexpected impacts. By minimizing the force transmitted to the protected object, this material significantly reduces the risk of damage or injury.

Additionally, the team used the metamaterial as a “force transmission material,” capable of transmitting forces to desired locations and times. By inputting specific digital commands, the material selectively operates adjacent LED switches, allowing precise control of force transmission pathways.

Professor Kim highlighted the compatibility of this metamaterial with artificial intelligence technologies, such as deep learning, as well as existing digital technologies and devices. “This metamaterial, capable of converting digital information into physical information in real time, will pave the way for innovative new materials that can learn and adapt to their environment,” added Professor Kim.

More information:

Jun Kyu Choe et al, Digital Mechanical Metamaterial: Encoding Mechanical Information with a Graphical Rigidity Model for Adaptive Software Machines, Advanced materials (2023). DOI: 10.1002/adma.202304302

Provided by Ulsan National Institute of Science and Technology

Quote: A research team develops a metamaterial to enable control of shapes and properties in real time (February 6, 2024) retrieved February 6, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.