Credit: Research in industrial and technical chemistry (2023). DOI: 10.1021/acs.iecr.3c02909

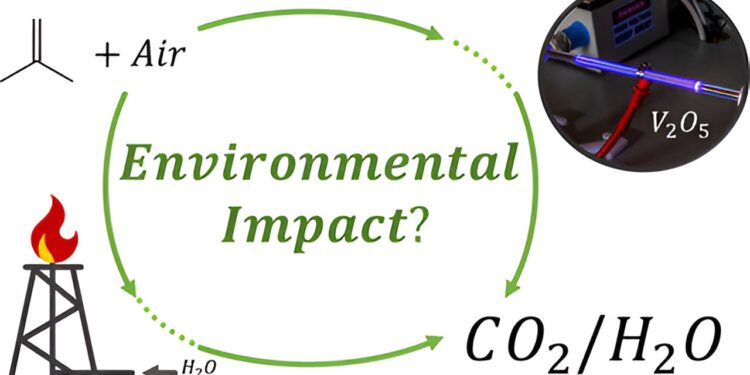

Researchers used new technology to create an electric torch that significantly reduces CO2 compared to gas flares currently used by oil refineries to control pollution.

Scientists from the University of Nottingham’s School of Chemistry have worked with industry partner Lubrizol and the University of Warwick to develop a non-thermal plasma electric torch to reduce carbon emissions.

The team showed that by eliminating the “fuel” from the flare, which is isobutylene gas, the “electric flare” consumes 6.6% less energy than an equivalent steam-assisted methane flare, with significant CO emissions.2 emissions reductions (between 2.0× and 11.4× lower).

Gas flares currently constitute the benchmark technology for industrial pollution control. Gas flares are ubiquitous in oil recovery and are often seen flickering above refineries and chemical plants where volatile byproducts must be disposed of with minimal environmental impact.

Recent reports from the BBC suggest that the impact of gas flaring on human health and the environment is much greater than previously thought, with pollutants from flaring including PM2.5, ozone, NO.2and benzo(a)pyrene (BaP), which at high levels or with continued exposure have been linked to stroke, cancer, asthma and heart disease according to international experts, including the World Health Organization (WHO).

The research was carried out by postdoctoral researcher Matteo Molteni from the University of Nottingham alongside experts from Lubrizol and the University of Warwick. The project is part of the University of Nottingham’s partnership with Lubrizol, a global leader in the specialty chemicals industry, and Warwick. The partnership aims to create cleaner, greener chemical processing methods in a bid to help the government achieve its carbon neutrality targets.

“This project highlights the importance of industry partnerships to drive sustainability innovation in chemical processes. The solution we developed in this research offers benefits in environmental performance, which, in the context of this industry, is essential. The next phase would be to “We will explore whether this technology can be used on a large scale for flaring chemicals,” says Professor Peter Licence, from the School of Chemistry and head of the industrial partnership at Nottingham.

“This is an exciting technology that potentially allows manufacturing plants to meet their environmental responsibilities without the need to burn natural gas, which could in turn reduce first-line emissions.” Lubrizol will continue collaborations with the University of Nottingham and third parties to study the scalability of non-thermal plasma for VOC destruction,” says Elizabeth Grove, Vice President of Sustainability and Public Affairs at Lubrizol.

The article is published in the journal Research in industrial and technical chemistry.

More information:

Matteo Molteni et al, Can “electric flares” reduce CO2 emissions? A case study with non-thermal plasma, Research in industrial and technical chemistry (2023). DOI: 10.1021/acs.iecr.3c02909

Provided by the University of Nottingham

Quote: Research shows electric flare technology significantly reduces carbon emissions (December 12, 2023) retrieved December 12, 2023 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.