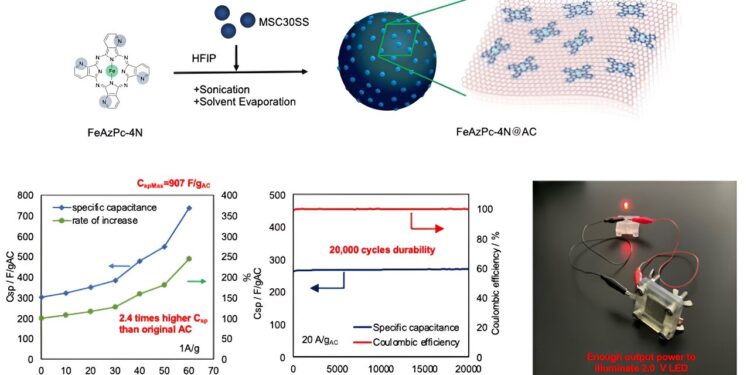

Schematic of activated carbon with adsorbed iron azophthalocyanine molecules (top), capacity and capacity increase ratio compared to activated carbon alone (bottom left), capacity and capacity retention rate after repeated charge-discharge cycles at 20 A/gAC (bottom center), and LED lighting experiment using a simple charge-discharge cell with two capacitor cells connected in series (bottom right). Credit: Hiroshi Yabu

Researchers at Tohoku University have succeeded in increasing the capacity, durability and cost-effectiveness of a capacitor in their quest for a more energy-efficient future. The research is published in the journal ACS Applied Materials and Interfaces.

A capacitor is a device used as part of a circuit that can store and release energy, much like a battery. What makes a capacitor different from a battery is that it takes much less time to charge. For example, your cell phone battery will power your phone instantly, but recharging that battery to 100% when it is dead is far from instantaneous.

Although capacitors seem like the best choice, they have a few major drawbacks that need to be overcome. First, their capacity is much lower than that of batteries, so they cannot store large amounts of energy at once. Second, they can be quite expensive.

In recent years, supercapacitors (increased capacity and performance) have been developed using nanocarbon materials, such as carbon nanotubes (CNTs), which increase the surface area and overall capacitance. However, due to the high cost of nanocarbon materials, large-scale production using this technique is not cost-effective.

In order to address these specific concerns to improve the overall performance of capacitors, a research group consisting of Professor Hiroshi Yabu (Tohoku University), AZUL Energy Co., Ltd. (a venture capital company of Tohoku University), and the AZUL Energy x Tohoku University Bio-Inspired GX Co-Creation Center was formed.

The team managed to increase the capacitors’ capacitance by 2.4 times (to 907 F/gAC) compared to carbon alone by “dusting” iron azophthalocyanine (FeAzPc-4N), a type of blue pigment, onto activated carbon.

This method allows the molecule to adsorb at the molecular level, using its redox capabilities. In addition, the study demonstrated that 20,000 charge-discharge cycles are possible even in high-charge regions of 20 A/gAC, which makes it possible to power LEDs.

“This increased lifespan compared to batteries can help reduce waste, as the same capacitor can be reused many times,” Yabu comments. “Capacitor components are also significantly less toxic than battery components.”

The capacitor electrode developed in this research can increase capacitance at the level of supercapacitors using carbon nanotubes while using commonly available and inexpensive activated carbon, making it a potential option for next-generation energy devices. The next step for the team is to make the supercapacitor even more powerful.

More information:

Kosuke Ishibashi et al, A molecular adsorption concept for increasing the energy density of hybrid supercapacitors, ACS Applied Materials and Interfaces (2024). DOI: 10.1021/acsami.4c06084

Provided by Tohoku University

Quote:Realization of a supercapacitor using the “molecular coating” approach (2024, September 4) retrieved September 4, 2024 from

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without written permission. The content is provided for informational purposes only.