Credit: ACS Applied Materials and Interfaces (2024). DOI: 10.1021/acsami.4c01045

Imagine knowing when your milk is expired without having to open your refrigerator. A technology called printed electronics could one day make such innovations possible.

Printed electronics refers to electronic circuits in the form of thin, flexible sheets. The technology is already used to make a wide range of products, from solar cells for vehicle roofs to flexible displays for smartphones.

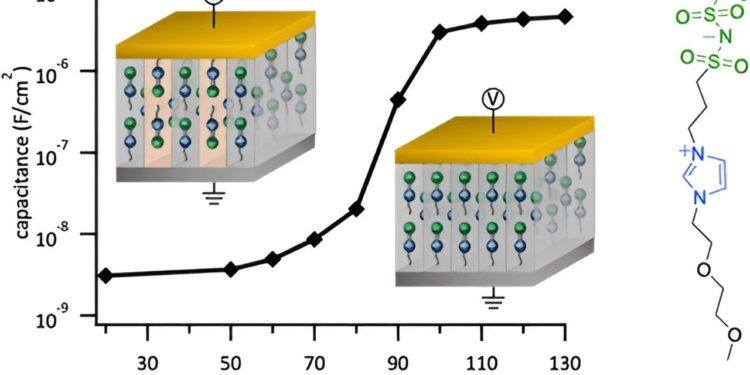

Using the Canadian Light Source (CLS) at the University of Saskatchewan (USask), a team of researchers from Simon Fraser University (SFU) and USask has developed a material that stores up to 1,000 times more charge than current forms of printed electronics.

The group’s work could take the Internet of Things to the next level. The Internet of Things involves adding printed electronic components to everyday objects (e.g., milk cartons and refrigerators) to enable communication between those objects and our smartphones and computers. Such a breakthrough could open up a world of technological possibilities. For the food industry alone, it would help minimize waste and spoilage at every level of the supply chain.

Making the Internet of Things a reality will require advanced circuits and operations that are only possible with electronic devices that can operate in both positive and negative voltage modes. That’s where the material developed by Loren Kaake, an associate professor in SFU’s department of chemistry, and his team shows promise.

“This is an area where it definitely outperforms the most advanced materials,” Kaake said. “I think this material has the potential to unlock and enhance the commercial potential of printed electronics.”

The team used the extremely bright synchrotron light of the CLS to analyze their material and improve its performance. They published their results in the journal ACS Applied Materials and Interfaces.

“The CLS allowed us to understand the nanoscale structure of our material and understand what enables good performance and what hinders it,” he explained. “The data we collected at the synchrotron give us insights into how to further improve material design.”

Kaake expects printed electronics to be commercially available within seven years. When that time comes, his hardware can be easily implemented when creating prototypes.

“Developing new materials is a very important research area because there is always the possibility of using a better material in an application if it is discovered,” he said. “If our material is suitable for future electronic printing techniques, it is a plug and play replacement.”

More information:

Simranjeet Kaur et al, Electrostatic correlations lead to high capacitance in thin films containing zwitterions, ACS Applied Materials and Interfaces (2024). DOI: 10.1021/acsami.4c01045

Provided by Canadian Light Source

Quote:Printed electronic material can store 1,000 times more charge than current forms (2024, August 19) retrieved August 19, 2024 from

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without written permission. The content is provided for informational purposes only.