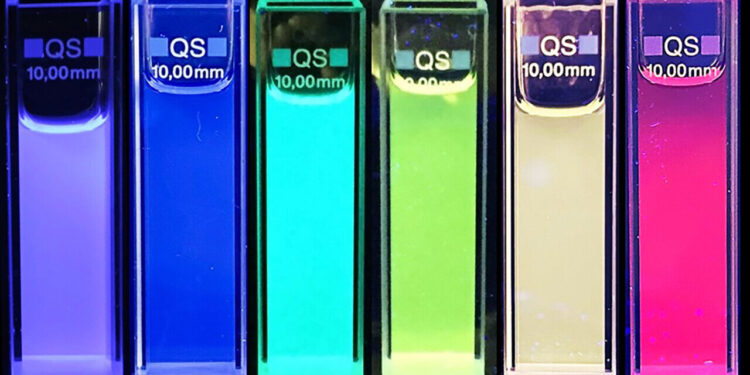

Carbon dot solutions emit various luminescences under UV illumination. All the carbon dots in the photograph are synthesized in Jia’s research laboratory. Credit: Jia Wang

Today, petrochemical compounds and rare metals such as platinum and iridium are used to produce semiconductors for optoelectronics, such as organic LEDs for ultrathin displays in televisions and cell phones. Physicists from Umeå University, in collaboration with Danish and Chinese researchers, have discovered a more sustainable alternative. By pressure cooking birch leaves picked from the Umeå University campus, they produced a nanometer-sized carbon particle with the desired optical properties.

“The essence of our research is to exploit nearby renewable resources to produce organic semiconductor materials,” explains Jia Wang, a researcher at the Department of Physics at Umeå University and one of the authors of the study published in Green chemistry.

Organic semiconductors are important functional materials in optoelectronic applications. One application is organic light-emitting diodes, OLEDs, made from ultra-thin, bright TV and cell phone screens. The sharply increasing demand for this cutting-edge technology is driving massive production of organic semiconductor materials.

Unfortunately, these semiconductors are currently produced primarily from petrochemical compounds and rare elements obtained through environmentally harmful mining activities. Additionally, these materials often contain “critical raw materials” that are rare, such as platinum, indium and phosphorus.

From a sustainability perspective, the ideal would be to use biomass from plants, animals and waste to produce organic semiconductor materials. These raw materials are renewable and abundantly available. Researcher Jia Wang and her colleagues from the Department of Physics, together with international partners, succeeded in producing such a semiconductor material of biological origin.

Birch leaves in a pressure cooker

The synthesis process is simple: they picked birch leaves on the Umeå campus and cooked them in a pressure cooker. This produced “carbon dots” about two nanometers in size that emit narrow-band dark red light when dissolved in ethanol. Some of the optical properties of these birch sheet carbon dots are comparable to commercial quantum dots currently used in semiconductor materials, but unlike them, they do not contain any heavy metals or critical raw materials.

“It is important to note that our method is not limited to birch leaves,” explains Jia Wang. “We tested different plant leaves with the same pressure cooking method, and all produced similar red-emitting carbon dots. This versatility suggests that the transformation process can be used in different locations.”

Using carbon dots from an electrochemical cell device, the researchers were able to show that the brightness generated was 100 cd/m.2which is comparable to the light intensity of a computer screen.

“This result shows that it is possible to move from the depletion of petroleum compounds to the regeneration of biomass as a raw material for organic semiconductors,” explains Jia Wang.

It highlights the broader potential of carbon dots beyond simple light-emitting devices.

“Carbon dots show promise in a variety of applications, from bioimaging and sensing to anti-counterfeiting. We are open to collaborations and keen to explore more interesting uses for these emissive and sustainable carbon dots,” says Jia Wang.

More information:

Shi Tang et al, Fluorescent carbon dots from birch leaves for durable electroluminescent devices, Green chemistry (2023). DOI: 10.1039/D3GC03827K

Provided by Umea University

Quote: Pressure cooking birch leaves to produce raw materials for organic semiconductors (November 28, 2023) retrieved November 29, 2023 from

This document is subject to copyright. Except for fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.