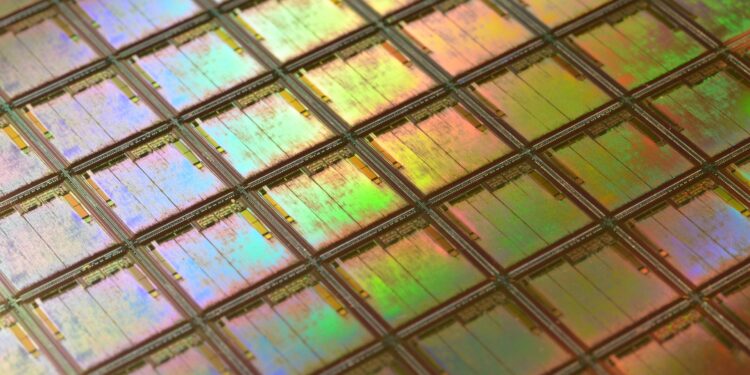

Credit: Unsplash/CC0 Public domain

Fashioned from the same element found in sand and covered in intricate patterns, electronic chips power smartphones, improve household appliances and make cars and planes easier to operate.

Today, scientists at the U.S. Department of Energy’s (DOE) Princeton Plasma Physics Laboratory (PPPL) are developing computer simulation codes that will outperform current simulation techniques and facilitate the production of microchips using plasma, the electrically charged state of matter also used in fusion research. .

These codes could help increase efficiency in the manufacturing process and potentially spur a renaissance of the U.S. chip industry.

“Because devices with microchips are essential to our daily lives, where and how they are made is a matter of national security,” said Igor Kaganovich, a senior physics researcher who leads the Low Temperature Modeling Group at the PPPL.

“Robust and reliable simulation tools, capable of accurately predicting plasma behavior and shortening the manufacturing and design cycle of silicon chips, could help the United States regain a leadership role in this field and to maintain it for decades.”

Pick up the pace

A PPPL research effort involves reducing the time it takes for computers to simulate microchip plasma reactors. This innovation would help private industry widely use more complex and accurate simulations and help reduce microchip costs.

“Companies would like to use simulations to improve their processes, but these are typically computationally expensive,” said Andrew Tasman Powis, co-author of the paper reporting the results in Plasma Physics and Computer Science Research Associate at PPPL. “We are doing our best to counter this trend.”

Physicists generally want simulations to reproduce plasma as accurately as possible, generating virtual images revealing the intricacies of plasma behavior in very fine detail. This process requires algorithms, programs following a set of rules, which simulate plasma in very short time increments and in small volumes of space.

The problem is that such detailed simulations require powerful computers running for days or even weeks. This time frame is too long and too costly for companies that want to use simulations to improve their microchip manufacturing processes.

The researchers delved into the history of plasma physics to find previously developed algorithms that could reduce the time needed to simulate plasma on a microchip. Researchers have found suitable algorithms dating back to the 1980s; When tested, the algorithms demonstrated the ability to model microchip plasma systems in significantly less time and with only a slight reduction in accuracy.

Essentially, the researchers found that they could get good simulations even if they modeled plasma particles in larger spaces and using longer time increments.

“This development is important because it could save companies time and money,” said Haomin Sun, lead researcher of the study and former graduate student in Princeton University’s plasma physics program. , based at PPPL.

“This means that with the same amount of computing resources, you can create more simulations. More simulations not only allow you to find ways to improve manufacturing, but also to learn more about physics in general. We can make more discoveries using our limited resources.”

Related research by Powis reinforces this possibility. In an article published in Plasma PhysicsPowis confirms that computer codes can generate precise models of plasma particles while using virtual “cells,” or small volumes of space, that exceed a standard measurement in plasma physics known as the Debye length.

This development means that codes can actually use fewer cells and reduce the calculation time required. “This is good news because reducing the number of cells could reduce the computational cost of the simulation and therefore improve performance,” Powis said.

The algorithms can simulate so-called “capacitively coupled plasma reactors,” which create the plasma that engineers use to etch narrow channels into a silicon wafer. These tiny passages form the microcircuits that allow the chip to function.

“We want to model this process so we can learn how to control the plasma properties, predict what they would look like in a new machine, and then predict the etch properties so we can improve the process,” Powis said.

The team plans to further test the algorithms by adding the effects of different types of wall materials and electrodes. “We want to continue to build confidence in these algorithms so that we can be confident that the results are accurate,” Powis said.

Recognize and overcome inherent limitations

Another research effort focuses on errors that can creep into plasma simulations due to inherent limitations in the simulation methods themselves, which model fewer plasma particles than are present in real plasma.

“When you simulate a plasma, you would ideally like to track each particle and know where it is at all times,” said Sierra Jubin, a graduate student in Princeton’s program in plasma physics and lead author of a paper reporting the results of Plasma Physics. “But we don’t have infinite computing power, so we can’t do that.”

To get around this difficulty, researchers are designing a code to represent millions of particles as one. giant particle. This simplifies the computer’s task, but also amplifies the interactions of the virtual megaparticles. As a result, a change in the proportion of particles moving at one speed to the number moving at another (a process known as thermalization) occurs more quickly than in nature. In fact, the simulation does not correspond to reality.

“This is a problem because if we don’t solve this problem, we won’t model phenomena as they actually happen in the world,” Jubin said. “And if we want to know how many electrons are moving at a particular speed, generating ions or reactive chemical species that interact with the materials used to make the microchips, we won’t get an accurate picture.”

To compensate for these miscalculations, the researchers found they could make the volumes of the megaparticles larger and less dense, thereby attenuating their interactions and slowing the particles’ changes in velocity. “Indeed, these results impose limits on what is possible in plasma simulations on microchips, highlight the constraints we must take into account, and propose solutions,” Jubin said.

Jubin’s findings reinforce the idea that current simulation techniques need improvement. Whether because the codes used today require small volumes and time increments that slow down simulations, or because they produce errors based on computational requirements, scientists need new solutions. “This is actually a paradigm shift in the field,” Kaganovich said, “and PPPL is leading the way.”

The team included researchers from Princeton University, the Swiss Plasma Center at École Polytechnique Fédérale de Lausanne, India’s Birla Institute of Technology and Science, India’s Homi Bhabha National Institute, from the University of Alberta in Edmonton, Applied Materials, Inc. and the Sino Chinese Institute. -French Institute of Nuclear Engineering and Technology.

More information:

Sierra Jubin et al, Numerical thermalization in 2D PIC simulations: practical estimates for low temperature plasma simulations, Plasma Physics (2024). DOI: 10.1063/5.0180421

AT Powis et al, Accuracy of the explicit particle method in the energy-conserving cell for sub-resolved simulations of capacitively coupled plasma discharges, Plasma Physics (2024). DOI: 10.1063/5.0174168

Haomin Sun et al, Direct implicit and explicit particle methods in the energy-conserving cell for modeling capacitively coupled plasma devices, Plasma Physics (2023). DOI: 10.1063/5.0160853

Provided by the Princeton Plasma Physics Laboratory

Quote: Plasma scientists develop computer programs that could lower the cost of microchips and boost manufacturing (February 21, 2024) retrieved February 21, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.