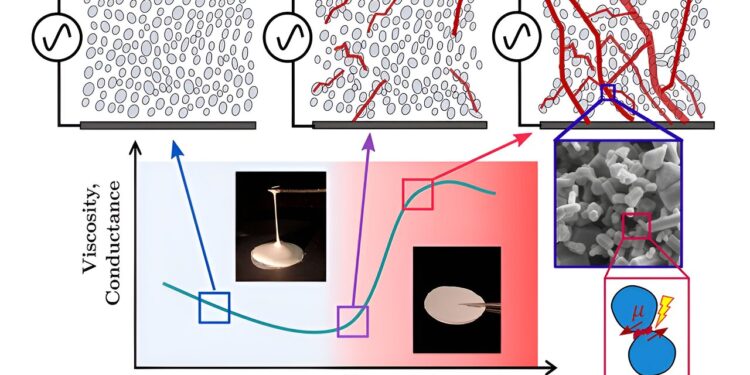

As a dense suspension of piezoelectric nanoparticles thickens due to a transition between frictionless (gray) and frictional (red) particle-particle interactions, friction-induced piezoelectricity in the contacting particles generates a electrical charge, which in turn increases the conductance of the environment. fluid. Credit: Proceedings of the National Academy of Sciences (2023). DOI: 10.1073/pnas.2310088120

If you mix cornstarch and water in the right proportions, you get something that looks not quite liquid but not quite solid. Oobleck sinks and settles like a liquid when left untouched, but stiffens when you try to pick it up or stir it with a spoon. The properties of oobleck and other non-Newtonian fluids, including Silly Putty, quicksand, paint, and yogurt, change under stress or pressure, and scientists have long struggled to prove exactly why.

Now, researchers at the Pritzker School of Molecular Engineering (PME) at the University of Chicago have used piezoelectric nanoparticles, which themselves change in response to pressure, to study the fundamental physics of non-Newtonian fluids. The team discovered the key role of friction between particles in moving materials from a fluid to a more solid structure.

“This not only answers long-standing fundamental questions about the physical origins of these materials, but also opens the door to the design of new non-Newtonian fluids with practical applications,” said Stuart Rowan, Barry L. MacLean Professor of molecular engineering and co. -main author of the article, published in Proceedings of the National Academy of Sciences.

Among these potential applications are paint that does not clump, liquids that harden in a mold when shaken, and wearable protective equipment that stiffens when touched.

Piezoelectric probes

A characteristic of non-Newtonian fluids is that their viscosity (their thickness) changes significantly when the materials are subjected to stress. For some materials this means thinning under stress. Shaking a bottle of ketchup can make the condiment considerably thinner; Yogurt, mayonnaise and toothpaste retain their shape in a container but become more liquid when used.

But other materials like oobleck, which is a concentrated suspension of particles, behave exactly the opposite: it can feel solid when handled, but collapse into a puddle when placed .

Scientists have hypothesized about why concentrated particle suspensions change when sheared, being exposed to multiple forces acting in different directions. These hypotheses primarily focus on how the molecules and particles that make up materials can interact with each other in different ways under different conditions, but each hypothesis is difficult to prove.

“To understand these concentrated particle suspensions, we want to be able to observe the structure at the nanoscale, but the particles are so incredibly crowded that it is very difficult to imagine these structures,” explained postdoctoral researcher Hojin Kim, first author of the new article. .

To tackle this challenge, Kim collaborated with Rowan, Aaron Esser-Kahn, also a professor at PME and an expert in piezochemistry, and Heinrich Jaeger, the Sewell Avery Distinguished Professor of Physics. The team developed a technique that measures the change in electrical conductance as a function of the shear force exerted on it. Then, they suspended the nanoparticle in a liquid at such a concentration that it exhibited non-Newtonian properties in the same way as oobleck.

The researchers applied a shear force to the top and bottom of the liquid and simultaneously measured the resulting changes in viscosity and electrical signals. This allowed them to determine how the particles interacted as they moved from a more liquid to a more solid material.

“We found that friction between particles was essential for this transition,” Kim said. “In this concentrated solution of particles, there is a tipping point when the friction reaches a certain level and the viscosity increases abruptly.”

A range of applications

Understanding the physical forces at play in a solution of concentrated particles is a step toward designing new non-Newtonian fluids in the laboratory. One day, these engineered materials could have custom properties that allow scientists to control their viscosity under stress. In some cases, this could result in less caking and clogging of liquids like paint and concrete. In other cases, this may involve deliberate hardening of materials when desired.

“For any application, we hope to eventually be able to determine the ideal combination of solvents, particles and shear conditions to achieve the desired properties,” Kim said. “This paper may sound like very basic research, but in reality, non-Newtonian fluids are everywhere, and so this has many applications.”

For now, the Pritzker Molecular Engineering and UChicago researchers plan to take advantage of the strain-induced piezoelectric activity of their nanoparticle suspensions to design new adaptive and responsive materials that, for example, become stiffer under the effect of a mechanical force.

More information:

Hojin Kim et al, Strain-activated friction in sheared suspensions probed with piezoelectric nanoparticles, Proceedings of the National Academy of Sciences (2023). DOI: 10.1073/pnas.2310088120

Provided by the University of Chicago

Quote: New understanding of “oobleck-like” fluids contributes to the design of smart materials (December 1, 2023) retrieved December 2, 2023 from

This document is subject to copyright. Except for fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.