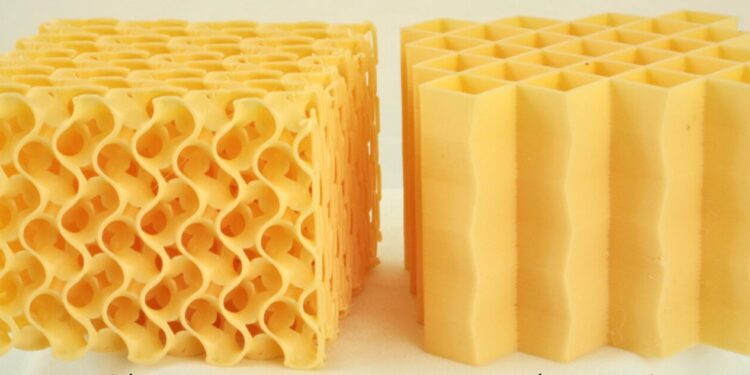

In lab tests, a new cushioning design, right, outperformed more conventional technologies like foam, left, made from the same elastic material. Credit: Lawrence Smith

Football players (and anyone else who takes a beating) may want to breathe a sigh of relief. In recent research, engineers at the University of Colorado Boulder and Sandia National Laboratories developed a new cushioning design that can withstand significant impacts. The team’s innovations, which can be printed on commercially available 3D printers, could one day result in everything from shipping crates to soccer mats, anything that helps protect fragile objects or bodies from vagaries of life.

The team described the technology in January in the journal Advanced materials technologies.

“Impact mitigation is something that’s important everywhere,” said Robert MacCurdy, corresponding author of the study and assistant professor in CU Boulder’s Paul M. Rady Department of Mechanical Engineering. “It is found in road safety barriers, knee and elbow pads, as well as packaging equipment.”

The research takes a new look at something most people encounter all the time but rarely notice: mosses. They are spongy materials filled with countless small holes and channels. Imagine packing peanuts or stress balls. MacCurdy said foams can be effective at absorbing hits, but they have a major drawback: If you squeeze a foam hard enough, it will eventually compress into a stiff wad.

He and his colleagues believe they can do better.

In the new study, the group wrote computer algorithms to meticulously redesign the interiors of cushioning materials, allowing them to deform under force, but only following a careful pattern. When the group tested their designs in the lab, they found their cushioning could absorb up to 25 percent more force than current state-of-the-art technologies.

“The material you use to absorb impacts is important,” MacCurdy said. “But what really matters is the geometry.”

Zoom in

To understand why some cushions work well and others don’t, it helps to look deep within yourself.

What gives a foam its spring, for example, are all these little nooks and crannies. When you squeeze a sponge, MacCurdy explains, these empty spaces begin to close, which, in turn, absorbs energy.

Some engineers have gone beyond this basic design. Instead, they make padding from a network of towers, or “plate lattices,” that look a bit like honeycombs. If a linebacker crashes into, for example, this type of cushion, the impact will cause the honeycombs to collapse in a wave-like pattern. This is a more efficient way to absorb forces.

But, MacCurdy noted, researchers have long been striving to create cushioning that meets a gold standard: technology that not only absorbs a lot of force, but can also absorb many different types of forces with equal smoothness.

“If you’re riding a bike and you have an accident, you don’t know if it’s going to be a low-speed or high-speed impact. But regardless, you expect your helmet to perform well” , did he declare. . “We’re trying to develop a geometry that works well in all of these scenarios.”

Give pressure

To create a more versatile cushion, the engineer and his colleagues chose to rearrange the interior of these objects, on the scale of a millimeter or less.

The group first used custom software to lay out a network of honeycombs, then tweaked them to include a few defects, much like the bellows of an accordion. These folds help guide the honeycombs as they collapse upon impact, allowing for a much smoother collapse.

“As soon as you start compressing these structures, they absorb a certain amount of force,” MacCurdy said. “The best absorber designs maintain a constant force throughout the compression range.”

In other words, unlike a foam, these cushions will behave the same no matter how hard you squash them – or at least up to a certain maximum.

The researchers also wanted to make sure their cushioning could withstand the bumps and bruises of the real world. They used a 3D printer to create blocks the size of a small brick from an elastic material called thermoplastic polyurethane. Then they pressed them with an impact testing machine.

The group found that its blocks could absorb about six times more energy than standard foams made from the same material, and up to 25 percent more than other honeycomb designs. MacCurdy and his colleagues are currently working to improve their structures even further. He added that engineers can make this type of design from many different types of materials, from inflatable plastics to harder substances like aluminum.

In other words, the world could soon become a lot kinder.

More information:

Lawrence Smith et al, Tunable Metamaterials for Impact Mitigation, Advanced materials technologies (2024). DOI: 10.1002/admt.202301668

Provided by University of Colorado Boulder

Quote: New types of padding could make football equipment and bicycle helmets safer than ever (February 5, 2024) retrieved February 5, 2024 from

This document is subject to copyright. Except for fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.