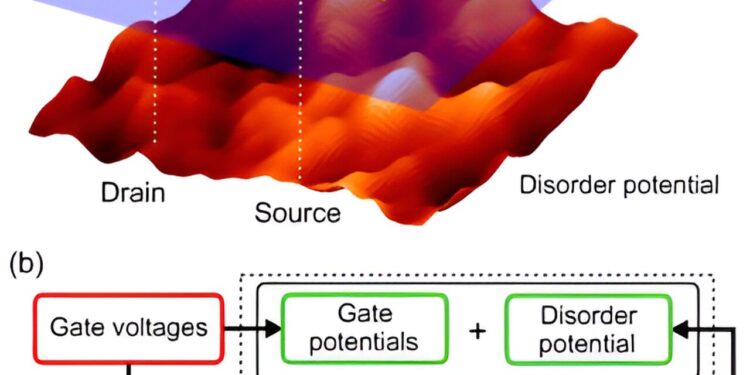

(a) Device geometry including the gate electrodes (labeled G1–G8), the donor ionic plane, and an example of the disorder potential encountered by the confined electrons. The typical current flow from source to drain is indicated by the white arrow. (b) Schematic of the disorder inference process. The colors indicate the following: red for experimentally controllable variables, green for quantities relevant to the electrostatic model, blue for the experimental setup, and yellow for machine learning methods. The dashed arrows represent the process of generating training data for deep learning approximation and are not part of the disorder inference process. Credit: Physical examination (2024). DOI: 10.1103/PhysRevX.14.011001

A study led by the University of Oxford used the power of machine learning to overcome a major challenge affecting quantum devices. For the first time, the results reveal a way to bridge the “reality gap”: the difference between behavior predicted and observed from quantum devices. The results were published in Physical examination.

Quantum computing could power a host of applications, from climate modeling and financial forecasting to drug discovery and artificial intelligence. But this will require efficient ways to evolve and combine individual quantum devices (also called qubits). A major obstacle to this situation is inherent variability, in which even seemingly identical units exhibit different behaviors.

Functional variability is assumed to be caused by nanoscale imperfections in the materials from which quantum devices are made. Since there is no way to measure them directly, this internal disorder cannot be captured in simulations, leading to a discrepancy between predicted and observed results.

To address this problem, the research group used a “physics-based” machine learning approach to indirectly infer the characteristics of these disorders. This was based on how the internal disorder affected the flow of electrons through the device.

Lead researcher Natalia Ares (Department of Engineering Science, University of Oxford) said: “By analogy, when we play ‘crazy golf’, the ball can enter and exit a tunnel at one speed or in a direction that does not correspond to our predictions. But with a few more shots, a crazy golf simulator and a little machine learning, we could better predict ball movements and close the gap with reality.

The researchers measured the output current across an individual quantum dot device for different voltage settings. The data was entered into a simulation, which calculated the difference between the measured current and the theoretical current in the absence of internal disorder.

By measuring current at many different voltage settings, the simulation was forced to find an arrangement of internal disorder that could explain the measurements at all voltage settings. This approach combined mathematical and statistical approaches coupled with deep learning.

Associate Professor Ares added: “In the crazy golf analogy, this would be equivalent to placing a series of sensors along the tunnel, so that we can take measurements of the speed of the ball at different points. Even though we still can’t see inside the tunnel. , we can use the data to better predict how the ball will behave when we shoot. »

Not only did the new model find suitable internal disorder profiles to describe the measured current values, but it was also able to accurately predict the voltage settings required for the specific operating regimes of the devices.

The model provides a new method for quantifying variability between quantum devices. This could enable more accurate predictions about device performance and help design optimal materials for quantum devices. This could inform compensation approaches to mitigate the unwanted effects of material imperfections in quantum devices.

Co-author David Craig, a Ph.D. student in the Department of Materials at the University of Oxford, added: “In the same way that we cannot directly observe black holes, but infer their presence from their effect on surrounding matter, we used simple measurements as an indicator of the internal variability of the quantum at the nanoscale. devices.”

“Although the actual device is even more complex than the model can capture, our study demonstrated the utility of using physics-aware machine learning to narrow the gap with reality.”

More information:

DL Craig et al, Bridging the reality gap in quantum devices with physics-aware machine learning, Physical examination (2024). DOI: 10.1103/PhysRevX.14.011001

Provided by the University of Oxford

Quote: New study uses machine learning to bridge reality gap in quantum devices (January 9, 2024) retrieved January 10, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.