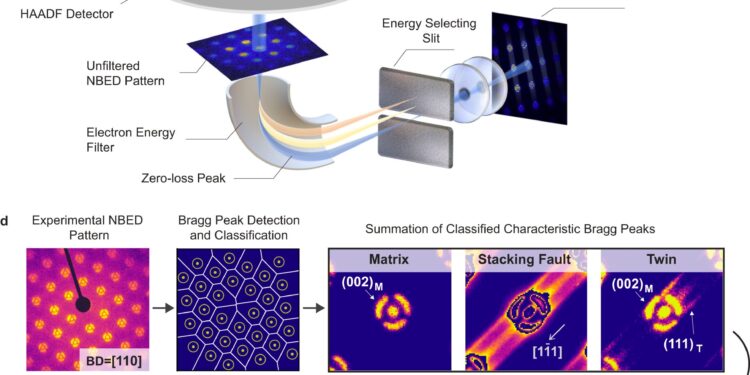

a) Schematic illustration of the experimental setup. b) Scanning electron microscopy (SEM) image showing the push-to-pull (PTP) device for cyclic tensile testing. c) SEM image showing a CrCoNi equiatomic medium entropy alloy (MEA) sample with a notch before mechanical testing. The loading direction is indicated by the white arrows. d) Illustration of the 4D-STEM data processing routine. e) Comparison of microscopy images acquired on the same region in a CrCoNi MEA sample after 1000 deformation cycles. Credit: Natural communications (2024). DOI: 10.1038/s41467-024-45696-z

A new class of metallic materials with potential applications in aircraft turbines, nuclear reactors and space exploration equipment can withstand extreme temperatures and resist fracture, but scientists didn’t understand why until here.

The answer may have to do with the material’s short-range order, or the local arrangement of atoms in a material, according to a new study co-led by Penn State researchers. This knowledge could lead to further improvement in the mechanical performance and damage tolerance of these materials, the researchers said, leading to advances in the safety and reliability of next-generation engineering systems for transportation or power stations.

Their results were published in Natural communications.

The team developed a new imaging method to study the local atomic arrangement of metallic materials, called high- and medium-entropy alloys (HEA/MEA), and focused their study specifically on the chromium-cobalt-nickel MEA ( CrCoNi) and its impacts on mechanical performance.

“The mechanical performance of CrCoNi is astonishing,” said co-corresponding author Yang Yang, assistant professor of engineering sciences, mechanics and nuclear engineering at Penn State, also affiliated with the Materials Research Institute. “For example, it was recently shown to have the highest resistance on Earth, at almost -423°F. But people didn’t know why it was so good.”

Penn State assistant professor Yang Yang co-led a study revealing the interplay between short-range order and planar defects, which could improve the mechanical performance of high- and medium-entropy alloys. Credit: Alan Jinglin Zhao

Some scientists, Yang said, have speculated that short-range order was responsible.

“But because short-range order is so small and subtle in materials, it is very difficult to observe or measure it in order to provide experimental proof,” said co-corresponding author Andrew M. Minor, professor of materials science and engineering at the university. University of California, Berkeley (UC Berkeley) and Lawrence Berkeley National Laboratory (LBNL).

CrCoNi contains three components: chromium, cobalt and nickel. Each element has the same atomic fraction in the alloy, and early studies assumed that each of the three types of atoms were randomly distributed in the system, according to Yang. However, Yang said recent studies show the material actually displays short-range order.

“Let’s imagine there’s a party with people from Penn State, Ohio State and North Carolina,” Yang said. “And, ideally, one would expect everyone to mix harmoniously, creating an even mix of individuals throughout the room. However, in practice, this is not always the case. Often, students of the same university tend to move closer to each other., drawn by shared experiences. This is a kind of short-term order, deviating from the anticipated random distribution.

To investigate the role of short-range order in CrCoNi, the team designed an experiment using an energy-filtered 4D scanning transmission electron microscopy (4D-STEM) system. In a 4D-STEM experiment, a nanometer-sized electron beam scans the sample, generating a nanobeam electron diffraction pattern for each spot.

According to Minor, they were able to capture hundreds of electron diffraction images every second, allowing them to analyze the evolution of material defects under stress with both a wide field of view and high resolution.

“Defects form during the process of mechanical deformation, and we actually found that there is a transition in the formation of a defect,” Minor said, noting that they focused specifically on defects planars, or “errors” in the stacking sequence of planes of atoms.

“We found that the planar defect is fully reversible during the initial cycles. If we deform it and then release the force, it recovers completely. However, after about a thousand cycles of mechanical deformation, this reversibility disappears. At this point, the defect tends to stay there after releasing the charge. And this transition, we think, is actually governed by the short-range order in this system.

Yang explained that this was because in the beginning the system had a lot of short-term orders that made reversible processes favorable. However, the deformation gradually destroys this small order, which directs the deformation mechanism towards another which favors this formation of a plane defect.

“Short-term order is like a moderator,” Yang said. “The local density of it, or its degree, controls which mechanism works or does not work. The synergy of various deformation mechanisms is essential for the high damage tolerance in this class of materials.”

By successfully providing a technique to visualize the evolution of planar defects in CrCoNi and integrating advanced atomistic modeling, researchers were able to reveal the interaction between short-range order and planar defects, which could improve the mechanical performance of these alloys.

More information:

Yang Yang et al, Rejuvenation as the origin of planar defects in medium entropy alloy CrCoNi, Natural communications (2024). DOI: 10.1038/s41467-024-45696-z

Provided by Pennsylvania State University

Quote: New structural knowledge could lead to mechanical improvement of alloys (February 22, 2024) retrieved February 22, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.