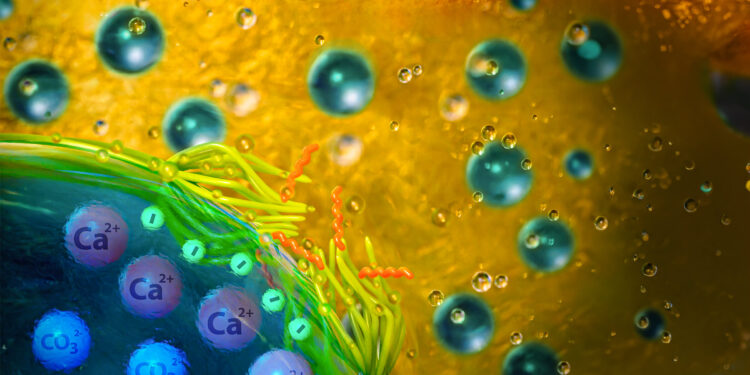

Cover of ACS Applied Materials and InterfacesCredit: Provided by Amir Sheikhi.

During the oil extraction process, the accumulation of hard minerals inside pipes and equipment can lead to serious operational damage, safety issues such as pipe explosions, and significant economic losses. Current methods of removing mineral deposits, however, can have a negative impact on the environment.

Penn State researchers have developed a new nanoparticle that can prevent scaling and stabilize a commonly used emulsion or liquid mixture, which could make oil extraction processes more efficient and less harmful to the environment, the team says. The material can also be used in other equipment that handles water-oil emulsions.

Their results were published in ACS Applied Materials and InterfacesThe work was also featured on the journal’s additional cover.

“We sought to address the challenge of calcium carbonate formation, known as scaling, in two-phase oil-water systems, which is faced by many water-based industries, such as oil and gas,” said corresponding author Amir Sheikhi, associate professor of chemical engineering and the Dorothy Foehr Huck and J. Lloyd Huck Early Career Chair in Biomaterials and Regenerative Engineering.

In many industries, such as oil and gas, pharmaceuticals, cosmetics and food, water coexists with an immiscible phase, such as an oil or organic solvent that cannot mix with water, creating a two-phase system. If this system becomes scaled, it can lead to serious operational and safety risks, according to Sheikhi, as it blocks pipes and destroys equipment.

“Current anti-scaling solutions either have negative environmental impacts or are limited to working only in single-phase aqueous media,” Sheikhi said.

To address this problem, Sheikhi and his team first synthesized a cellulose-based nanoparticle, called anionic hairy cellulose nanocrystals (AHCNCs), which can prevent scale formation but cannot stabilize water-in-oil emulsions.

They then developed a new type of bio-derived multifunctional nanoparticle, called amphiphilic hairy cellulose nanocrystals (AmHCNCs), with unique chemical and structural properties that not only prevent scale formation but also stabilize water-in-oil emulsions, which are common in oil extraction processes, the researchers said.

“Our innovation lies in nanoengineering a type of nanoparticle, AmHCNC, that simultaneously prevents scaling and stabilizes water-in-oil emulsions through the Pickering mechanism, a combination that has never been achieved,” Sheikhi said. The Pickering mechanism refers to a process that stabilizes the interface between two immiscible solvents with small solid particles, such as nanoparticles.

“These anti-scaling particles are bio-based, environmentally friendly and cost-effective, providing a sustainable solution to the long-standing industrial problem of scale.”

The researchers are now looking for partners to test their technology in real-world conditions, such as in enhanced oil recovery, to assess its performance on a larger scale. They also plan to explore potential applications in other sectors, such as cosmetics and food.

“This technology can provide new opportunities for sustainable and safer industrial practices,” said Sheikhi, who also holds courtesy appointments in the Department of Biomedical Engineering in the College of Engineering, the Department of Chemistry in the Eberly College of Science and the Department of Neurosurgery in the College of Medicine.

More information:

Roya Koshani et al, Pickering antiscaling emulsions enabled by amphiphilic hairy cellulose nanocrystals, ACS Applied Materials and Interfaces (2024). DOI: 10.1021/acsami.4c03451

Provided by Pennsylvania State University

Quote:New nanoparticle prevents mineral buildup in equipment handling water-oil mixtures (2024, September 25) retrieved September 25, 2024 from

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without written permission. The content is provided for informational purposes only.