This innovative method not only helps maintain building safety, but also offers potential benefits on two other important aspects of today’s economy: costs and reduced carbon emissions. Credit: Danilo Mustafa

Concrete is an essential material in the construction sector, where it is fundamental for the foundations and structures of homes and office buildings, as well as for roads, dams and bridges, among many other construction projects. infrastructure. However, the lifespan of concrete is limited and must be monitored in order to guarantee the safety of these structures.

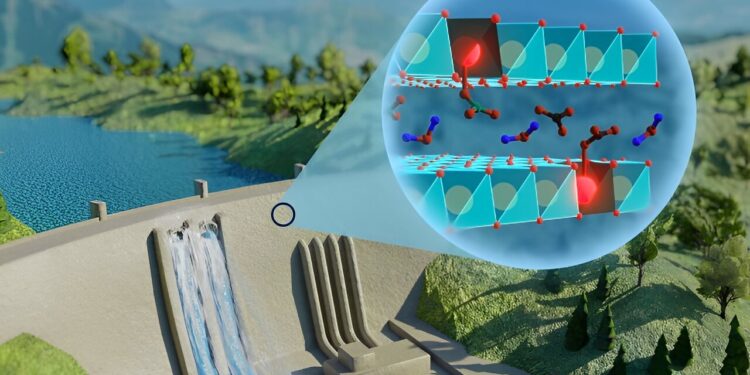

To facilitate rapid and inexpensive in situ analysis that avoids taking samples in a laboratory, researchers from the Institute of Physics of the University of São Paulo (IF-USP) in Brazil, in collaboration with colleagues from the The University of Louvain in Belgium, have developed a luminescent material that reveals the presence of compounds indicating deterioration of concrete when exposed to ultraviolet light.

The results are reported in an article published in Chemical communications and appeared on the cover of the newspaper.

Concrete structures last on average around 50 years. The constant absorption of water, salts and gases from the atmosphere causes acidification, leading to corrosion of steel reinforcing bars (rebar) slabs, columns and other structural elements , and considerably reducing their bearing capacity.

The lifespan of concrete can be extended through preventive measures such as adding protective layers that prevent the penetration of carbon dioxide (CO2) in exposed surfaces of structures. For this intervention to be timely, the ability to verify and characterize the degree of deterioration is vital.

The main challenge faced by engineers inspecting the condition of concrete in buildings and other structures is that drilling to take samples and analyze them in the laboratory is labor intensive and expensive, in addition to being complex in hard-to-reach places. It can also be dangerous, as drilling can cause structural alterations and further weaken the concrete if it is already degraded, especially if the procedure is not carried out correctly.

In this study, researchers at the IF-USP Laboratory of Nanomaterials and Applications (LNA) developed a layered double hydroxide (LDH) catalyst, also known as anionic clay, to measure the degree of deterioration of the concrete. They added trivalent europium (EU3+) to produce orange to red luminescence.

Laboratory tests showed that when the material was exposed to ultraviolet (UV) light, its luminescence changed color depending on the amount of carbonate absorbed. This effect can be used to detect concrete deterioration: the greater the redshift, the greater the quantity of carbonate and the more degraded the concrete.

“The key advancement is that the material can help determine in real time how the concrete in a structure is deteriorating and when the structure will require maintenance, without the need to drill or wait for laboratory analysis. This contributes to more agile decision-making. , facilitates preventive maintenance and helps avoid accidents that can cost lives and cause considerable economic damage,” said Alysson Ferreira Morais, first author of the article.

According to the scientists, the next step will be to develop a sensor that detects the luminescent material and test it in real conditions to check specific factors such as weather resistance and stability inside the concrete.

Safety, cost and carbon footprint

In addition to its contribution to building safety, the new method offers potential benefits on two other very important aspects of today’s economy: costs and the reduction of carbon emissions.

“The longer buildings last, the less there is a need to invest in new structures and the more the construction sector contributes to the effort to reduce greenhouse gas emissions, 8% of which come from industry at global level, due to concrete production and construction itself,” said Danilo Mustafa, last author of the article and professor at IF-USP.

Researchers from the University of Kiel in Germany also participated in the study.

More information:

Alysson F. Morais et al, Eu3+ doped with double hydroxides in ZnAl layers as calibration-free fluorescent sensors for carbonate, Chemical communications (2023). DOI: 10.1039/D3CC03066K

Quote: New material makes it easier to measure concrete deterioration in buildings and other structures (January 23, 2024) retrieved January 23, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.