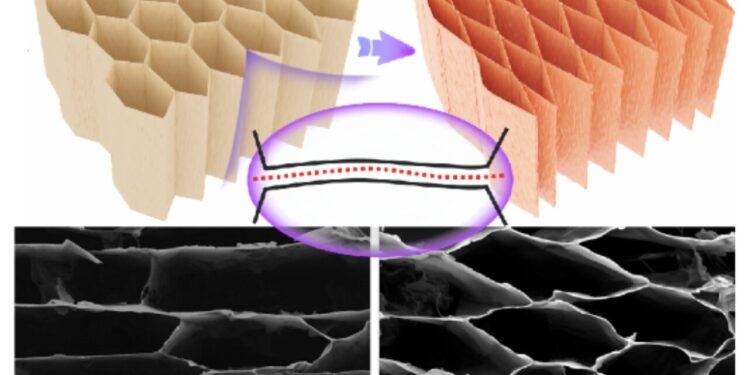

Graphene aerogels show potential for high-performance pressure sensors in human-machine interfaces due to their mechanical properties and conductivity. Anisotropic chitosan graphene oxide (CS-GO) airgel metamaterials with a highly ordered honeycomb microstructure were synthesized by conventional directional freeze casting. Subsequently, the cross-linked chitosan-reduced graphene oxide (CCS-rGO) airgel, with buckling network obtained by heating and post-cross-linking at 180 °C for 3 hours, exhibits directional hyperelasticity with sensitivity ultra high (121.45 kPa-1) and durability (20,000 compression cycles at 70%) as a pressure sensor. Credit: Wang et al.

In recent years, researchers have synthesized various new materials that could be used to develop more advanced robotic systems, devices, and human-machine interfaces. These materials include graphene aerogels, ultralight, porous, graphene-based materials made of a single layer of carbon atoms arranged in a 2D honeycomb lattice.

While graphene aerogels have many advantageous properties, including minimal weight, high porosity, and good electrical conductivity, engineers who have attempted to use them to develop pressure sensors have encountered some difficulties. Specifically, many of these materials have an inherently rigid microstructure, which limits their strain-sensing capabilities.

Researchers from Xi’an Jiaotong University, Northumbria University (UK), UCLA, University of Alberta and other institutes recently introduced a new manufacturing strategy for synthesize airgel metamaterials to overcome this limitation. This strategy, described in an article by Nanolettersmanufactures a durable graphene oxide-based airgel metamaterial that exhibits remarkable sensitivity to human touch and movement.

“The research was purely driven by my student’s curiosity, occasionally detecting an anomalous structural change in the cross section of a particular plane,” Dr. Ben Xu, co-author of the paper, told Phys.org . “This anisotropic phase change sparked interest. We quickly realized that the associated change in function could enable a nice directional pressure sensing function.”

The team’s strategy for making graphene oxide-based metamaterials spans two key steps. These include the use of a dehydration technique known as freeze-drying and a heat treatment process called annealing.

“The pre-solution also contains a specific chemical that acts as a graphene ‘glue’ to build the honeycomb-like cross-section,” explained Dr. Xu. “The structural configuration of the cross section on the dedicated plane is achieved by thermal annealing, which can be adjusted by micro/nanomechanics. Through this simple strategy, the deformed cross section was obtained in the first test.”

Using the proposed fabrication strategy, Dr. Xu and co-workers synthesized anisotropic cross-linked chitosan airgel-reduced graphene oxide (CCS-rGO) metamaterial. This material has been shown to exhibit remarkable directional hyperelasticity, extraordinary durability, excellent mechanical and electrical performance, long sensing range, and very high sensitivity to stimuli of 121.45 kPa.-1.

“We currently conduct multidisciplinary research with diverse interests in functional materials and energy technology, sustainable engineering, healthcare materials, materials chemistry, responsive materials/surfaces, and microengineering,” said said Dr. Xu.

Dr Xu’s team at Northumbria University is currently carrying out further studies aimed at developing promising metamaterials for various technological applications. In the future, the proposed manufacturing strategy could contribute to the synthesis of additional graphene oxide-based airgel metamaterials, which could advance human-machine interfaces for advanced healthcare and prosthetics.

Another avenue for developing such sensors concerns wind energy.

“We have recently focused a lot on functional materials and engineering technology for the offshore wind energy sector,” added Dr. Xu. “We also look forward to applying our materials and sensors research under the new EU COST Action CA23155, to advance new ocean tribology. This project focuses on offshore wind energy, which contributes to the global goal of net zero emissions and sustainability.

More information:

Yuhao Wang et al, Microstructure-reconfigured graphene oxide airgel metamaterials for ultrarobust directional sensing at human-machine interfaces. NanoLetters(2024). DOI: 10.1021/acs.nanolett.4c03706

© 2024 Science X Network

Quote: New manufacturing strategy improves sensitivity and durability of graphene airgel for human-machine interfaces (October 18, 2024) retrieved October 18, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.