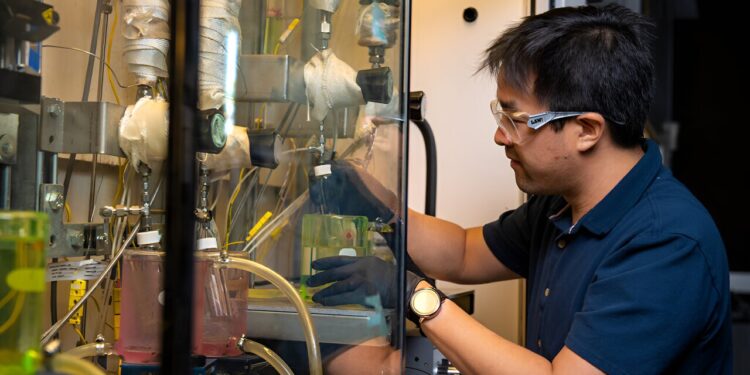

Working in Richland, Washington, Daniel Santosa, a doctoral student at Washington State University and a scientist at the Pacific Northwest National Laboratory, is testing a continuous process developed at WSU that turns lignin, a polymer found in plants, into jet fuel. Credit: Washington State University

Washington State University scientists have successfully tested a new way to produce sustainable jet fuel from lignin-based agricultural waste. Published in the journal Fuel processing technologyThe team’s research demonstrated a continuous process that directly converts lignin polymers, one of the main components of plant cells, into a form of jet fuel that could help improve the performance of sustainably produced aviation fuels .

“Our achievement brings this technology closer to real-world use by providing data that allows us to better assess its feasibility for commercial aviation,” said lead scientist Bin Yang, professor in the Department of Biological Systems Engineering at WSU.

A class of structural molecules that make plants strong and woody, lignin is derived from corn stalks (the stalks, cobs, and leaves left after harvest) and other agricultural byproducts.

The team developed a process called “simultaneous depolymerization and hydrodeoxygenation,” which breaks down the lignin polymer and at the same time removes oxygen to create lignin-based jet fuel. At their Richland facility, the scientists fed a dissolved lignin polymer into a continuous hydroprocessing reactor to produce the fuel.

Global aviation fuel consumption reached a record high of nearly 100 billion gallons in 2019, and demand is expected to increase over the coming decades. Sustainable aviation fuels derived from plant biomass could help minimize aviation’s carbon footprint, reduce contrails and meet international carbon neutrality targets.

Lignin-based jet fuel could make sustainable fuels cleaner and more easily usable in jet engines. Thanks to their density, efficiency and joint swelling characteristics, hydrocarbons catalyzed from lignin could effectively replace fossil fuel-derived compounds called aromatics. Associated with contrails and climate impacts, aromatics remain in use because they improve fuel density and help swell the O-rings of metal-to-metal seals.

Trickling bed reactor used for direct and continuous SDHDO of lignin. Credit: Fuel processing technology (2024). DOI: 10.1016/j.fuproc.2024.108129

This research marked the team’s first successful test of a continuous process, more feasible for commercial production. The project also used a less processed and less expensive form of lignin derived from corn stover, called “technical lignin,” contrasting with similar research using extracted lignin bio-oil.

The team’s findings suggest that lignin is a promising source of aromatic cycloalkanes and other useful fuel compounds.

“The aviation company is looking to generate 100% renewable aviation fuel,” said Josh Heyne, research team member and co-director of the WSU-PNNL Bioproducts Institute. “Lignin-based jet fuel complements existing technologies, for example by increasing the density of fuel blends.”

Offering reduced emissions, lignin-based fuel could ultimately make sustainable aviation fuels fully “drop-in”, meaning they can be used with all existing engines, infrastructure and aircraft, such as fuel aircraft of existing fossil origin.

“We are working to create an efficient and commercially relevant technology for a complementary blending component capable of achieving the goal of 100% direct addition,” Heyne said.

The team is now working to refine its process for greater efficiency and cost reduction.

More information:

Adarsh Kumar et al, A simultaneous depolymerization and hydrodeoxygenation process to produce lignin-based jet fuel in a continuous flow reactor, Fuel processing technology (2024). DOI: 10.1016/j.fuproc.2024.108129

Provided by Washington State University

Quote: New continuous reaction process can help turn plant waste into sustainable aviation fuel (September 26, 2024) retrieved September 26, 2024 from

This document is subject to copyright. Except for fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.