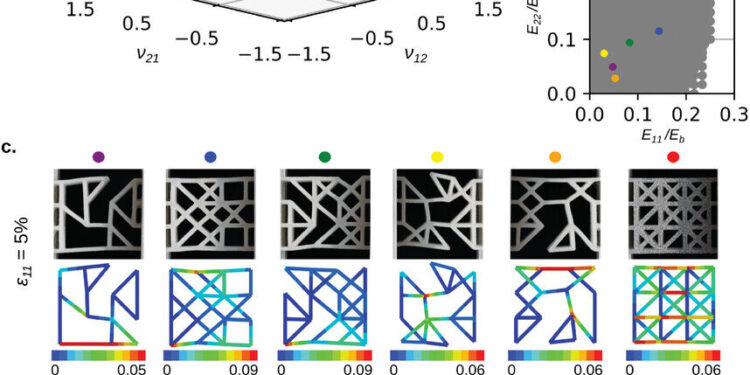

A schematic illustration and elastic properties of RN unit cells along with the network architecture of the unit cell elastic properties model. Credit: Advanced materials (2023). DOI: 10.1002/adma.202303481

A coating capable of hiding objects in plain sight or an implant that behaves exactly like bone tissue: these extraordinary objects are already made from “metamaterials”. Researchers at TU Delft have now developed an AI tool that not only can discover such extraordinary materials, but also makes them manufacturable and sustainable. This makes it possible to create devices with new features. They published their findings in Advanced materials.

Properties of normal materials, such as stiffness and flexibility, are determined by the molecular composition of the material, but the properties of metamaterials are determined by the geometry of the structure from which they are constructed. Researchers design these structures digitally and then have them printed in 3D. The resulting metamaterials can exhibit unnatural and extreme properties. For example, researchers have designed metamaterials which, although solid, behave like a fluid.

“Traditionally, designers use the materials they have available to design a new device or machine. The problem is that the range of properties of available materials is limited. Some properties we would like to have simply do not exist in the nature. Our approach is: tell us what properties you want to have and we design an appropriate material with these properties. What you will then get is not really a material but something between a structure and a material, a metamaterial,” explains the professor. Amir Zadpoor from the Department of Biomechanical Engineering.

Inverted design

Such a material discovery process requires solving an “inverse problem”: the problem of finding the geometry that gives rise to the desired properties. Inverse problems are notoriously difficult to solve, and that’s where AI comes in. Researchers at TU Delft have developed deep learning models that solve these inverse problems.

“Even when inverse problems have been solved in the past, they have been limited by the simplifying assumption that small-scale geometry can be realized from an infinite number of basic elements. The problem with this assumption “Metamaterials are typically made by 3D printing. And real 3D printers have limited resolution, which limits the number of basic elements that can fit into a given device,” explains first author Dr. Helda Pahlavani. .

The AI models developed by TU Delft researchers innovate by circumventing these simplifying assumptions. “So we can now simply ask: How many building blocks does your manufacturing technique allow you to fit into your device? The model then finds the geometry that gives you the desired properties for the number of building blocks you can actually make.”

Unleash all potential

A major practical issue overlooked in previous research is the durability of metamaterials. Most existing models break after being used several times. Indeed, existing approaches to metamaterial design do not take sustainability into account.

“Until now, it was only about the properties that could be achieved. Our study takes sustainability into account and selects the most sustainable designs from a wide range of candidate designs. This makes our designs truly practical and not just adventures theoretical,” explains Zadpoor.

The possibilities of metamaterials seem endless, but their full potential is far from being exploited, explains Assistant Professor Mohammad J. Mirzaali, corresponding author of the publication. Indeed, the search for the optimal design of a metamaterial today still relies largely on intuition, involves trial and error and therefore requires a lot of work. Using an inverse design process, where the desired properties are the starting point of the design, is still very rare in the field of metamaterials.

“But we think the step we’ve taken is revolutionary in the field of metamaterials. It could lead to all sorts of new applications.” There are possible applications in orthopedic implants, surgical instruments, soft robots, adaptive mirrors and exo-suits.

More information:

Helda Pahlavani et al, Deep learning for size-independent inverse design of random array 3D printed mechanical metamaterials, Advanced materials (2023). DOI: 10.1002/adma.202303481

Provided by Delft University of Technology

Quote: New AI tool discovers realistic “metamaterials” with unusual properties (February 9, 2024) retrieved February 9, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.