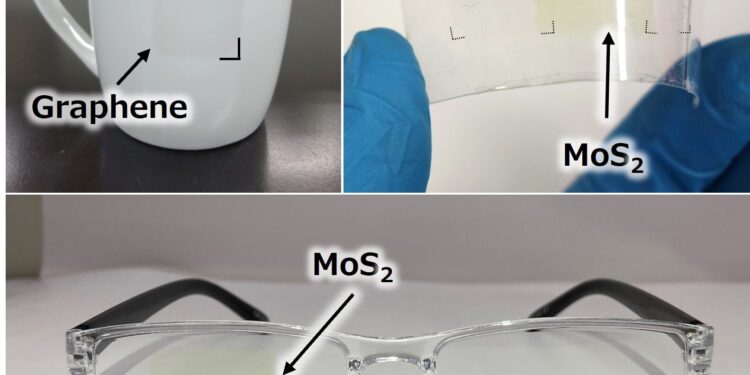

The newly designed UV ribbon is capable of transferring 2D materials, including graphene and transition metal dichalcogenides, onto a range of different substrates, including silicon, ceramics, glass and plastic. Credit: Ago Lab, Kyushu University

Materials a few atoms thick, known as two-dimensional (2D) materials, are set to revolutionize future technologies, including in the electronics industry. However, the commercialization of devices containing 2D materials has faced challenges due to the difficulty of transferring these extremely thin materials from where they are fabricated onto the device.

Now, a research team from Kyushu University, in collaboration with the Japanese company Nitto Denko, has developed an adhesive tape that can be used to stick 2D materials to many different surfaces in a simple and user-friendly way. The results were published in Natural electronics on February 9, 2024.

“2D material transfer is typically a very technical and complex process; the material can easily tear or become contaminated, significantly degrading its unique properties,” explains lead author Professor Hiroki Ago of the Global Innovation Center at Kyushu University. “Our tape offers a quick and easy alternative and reduces damage.”

Researchers began by focusing on graphene. Made from a thin sheet of carbon atoms, graphene is strong, flexible and lightweight, with high thermal and electrical conductivity. Nicknamed a “miracle material” upon its discovery, it has potential applications in the fields of biosensing, anti-cancer drug delivery, aeronautics and electronic devices.

“One of the main methods of making graphene is through chemical vapor deposition, where the graphene is grown on a copper film. But to work properly, the graphene must be separated from the copper and transferred to an insulating substrate, such as silicon,” explains Professor Ago. .

“To do this, a protective polymer is placed on top of the graphene, then the copper is removed using an etching solution, such as an acid. Once attached to the new substrate, the protective polymer layer is then dissolved with a solvent. This process is expensive, time-consuming, and can cause defects on the surface of the graphene or leave traces of the polymer.

Professor Ago and his colleagues therefore sought to propose an alternative way of transferring graphene. They used AI to develop a specialized polymer strip, dubbed a “UV strip,” that changes its attraction to graphene when irradiated with UV light.

Researchers from Kyushu University and Nitto Denko have developed a tape that changes its “stickiness” to 2D materials using UV light. Credit: Ago Lab, Kyushu University

Before exposure to UV light, the tape exhibits strong adhesion to graphene, allowing it to “stick.” But after exposure to UV, the atomic bond changes, which decreases the level of adhesion to graphene by about 10%. The UV tape also becomes slightly stiffer and easier to peel. Taken together, these changes allow the ribbon to be peeled off the device substrate while leaving the graphene behind.

The researchers also developed tapes capable of transferring two other 2D materials: white graphene (hBN), an insulator that can act as a protective layer when stacking 2D materials, and transition metal dichalcogenides (TMDs), a promising material for the next generation of semiconductors. .

Importantly, when the researchers looked closely at the surface of the 2D materials after transfer, they found a smoother surface with fewer defects than when transferred using today’s conventional technique. After testing the properties of the materials, they also found that they were more efficient.

UV ribbon transfer also offers many other advantages over current transfer techniques. Since the UV band is flexible and the transfer process does not require the use of plastic-dissolving solvents, flexible plastics can be used as the device substrate, expanding the potential applications.

“For example, we made a plastic device that uses graphene as a terahertz sensor. Like X-rays, terahertz radiation can pass through objects that light cannot pass through, but does not harm the body,” explains the Professor Ago. “It’s very promising for medical imaging or airport security.”

Researchers at Kyushu University showed that using UV tape to transfer graphene instead of polymer better maintained the integrity of the material and reduced defects. Credit: Ago Lab, Kyushu University

Additionally, the UV strip can be cut to size so that only the exact amount of 2D material needed is transferred, minimizing waste and costs. 2D layers of different materials can also be easily superimposed in different orientations, allowing researchers to explore new properties emerging from the stacked materials.

For their next steps, the researchers aim to expand the size of the UV band to the scale needed by manufacturers. Currently, the largest graphene wafer that can be transferred is 10 cm in diameter. Professor Ago and his colleagues are also trying to solve the problem of wrinkles and bubbles that form on the tape, causing small defects.

The research team also hopes to improve stability, so that 2D materials can be fixed on UV strips for a longer period of time and distributed to end users, such as other scientists.

“End users can then transfer the material to their chosen substrate by applying and removing the UV tape like a child’s sticker, with no training required,” says Professor Ago. “Such a simple method could fundamentally change the research style and accelerate the commercial development of 2D materials.”

More information:

Two-dimensional materials ready to transfer using adjustable adhesive strength strips, Natural electronics (2024). DOI: 10.1038/s41928-024-01121-3

Provided by Kyushu University

Quote: New adhesive tape picks up and sticks 2D materials as easily as child’s play (February 9, 2024) retrieved February 9, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.