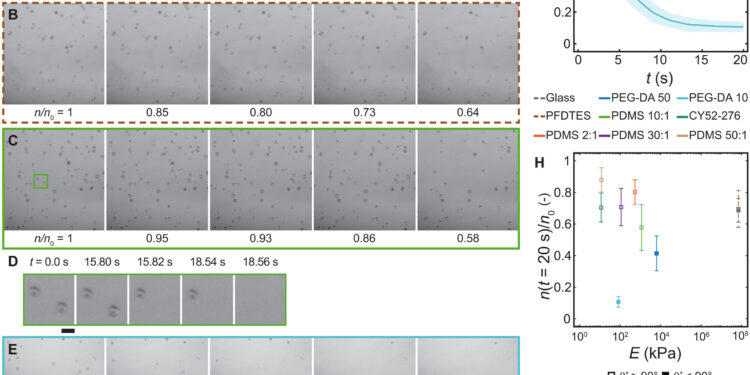

Dynamics of microfouling under shear-driven water flow. Bottom view image sequence showing calcium carbonate crystallites on (A) uncoated glass, (B) glass coated with 1H,1H,2H,2H-perfluorodecyltriethoxysilane (PFDTES), (C) glass coated with polydimethylsiloxane (PDMS 10:1) (coating thickness, δ ≈ 10 μm), and (E) poly(ethylene glycol) diacrylate (PEG-DA 10) – coated glass (δ ≈ 10 μm) immersed in water and subjected to a shear flow (from t = 0 s, the flow increases from 7 to 103 ml/min in a channel of 80 μm height, which gives an overall speed = 0.2 to 6 ms−1). The inset image reveals that the diameter of the crystallites is approximately 5 to 15 µm. Zoom images showing the removal of single crystallites from (D) PDMS 10:1 and (F) PEG-DA 10 compliant substrates. We define the number of crystallites visible on the surface as n and its initial value, n0. (G) Temporal evolution of n/n0 for various coatings on glass substrates. The lines representing mean values and shaded regions are the standard deviation for e ≥ 9 experiments on N = 3 independent samples. (H) Influence of stiffness and wettability on n(t = 20 s)/n0 for various coatings on glass substrates. Scale bars, (A) to (C) and (E) 100 μm; inset: (A) 10 μm and (D) and (F) 10 μm. Credit: Scientists progress (2023). DOI: 10.1126/sciadv.adj0324

The crystallization fouling process is a phenomenon of scale formation on surfaces. It is widespread in nature and technology and affects the energy and water sectors. Despite previous attempts, rationally designed surfaces with intrinsic strength remain elusive due to a lack of understanding of how microfoulants adhere in dynamic aqueous environments.

In a study now published in Scientists progressJulian Schmid and a team of surface engineering researchers in Switzerland and the United States studied the interfacial dynamics of microfouling using a micro-scanning fluid dynamic gauge system to demonstrate a rationally developed coating that removes 98% of deposits under shear flow conditions.

The dynamics of water and energy

Water and energy are interconnected resources, where water is needed to produce energy for water transportation, desalination and treatment. However, the limited nature of these resources and growing global challenges, including climate change and population growth, are putting them under increasing pressure. Passive methods to repel scale formation include surface engineering, interface materials, and coatings, which are attractive alternatives when it comes to sustainability and are also cost-effective.

Researchers had also previously focused on developing rigid antifouling surfaces that change the surface energy of materials to eliminate fouling. Materials scientists have shown increasing interest in developing interface materials and coatings that improve antifouling properties by utilizing the barriers inherent in the material.

In this new work, Schmid and colleagues developed a new method to study the physics of microfouling adhesion and created a microscanning fluid dynamics gauge. The scientists revealed three underlying microfouling removal mechanisms to design a microtextured coating and tested its scalability under laminar and turbulent flow conditions. The results can shed light on crystallization and particle fouling properties and lead to the design of interface materials as antifouling surfaces to address water-energy nexus challenges.

Bio-inspired materials

Nature presents exceptional examples of super-wettability and transport systems that have contributed to the development of bioinspired repellant substrates for studying the dynamics of crystallite-water interactions. Schmid and colleagues quantified microfouling removal from substrates with varying compliance by determining their surface wettability. For example, to remove calcium carbonate crystallites, the team used adjustable laminar water shear flow and simultaneously visualized the process by pumping water through a glass capillary to generate shear stress .

Schmid and his team also quantified the passive shear-driven process of aggregate removal. For example, when the team applied the method to a rigid glass substrate that had undergone fouling by crystallization under shear flow, they observed how the number of crystallites on the surface changed from the initial value. Such glass surfaces can be made hydrophobic by treatment with fluorosilane and a soft silicone to highlight the complex nature of substrate-crystallite interactions and demonstrate surface properties with microfouling.

Microfouling models

Individual crystallite removal events were rapid, which has substantial implications for antifouling or scalar materials as it allows crystallite removal before stubborn scale layers accumulate. To understand the mechanisms underlying increased repulsion toward a scale-based coating, materials scientists replaced complex crystallites of varying sizes with spherical polystyrene microparticles of comparable size to study the effect of shearing water, their Young’s modulus, their wettability and their thickness.

In addition to crystallization fouling, Schmid and his team used particulate fouling by depositing microfoulants on the coating as another subset of the method. Most microfoulants were smaller than the coating thickness, although ice and hydrate foulants exceeded this thickness. The scientists performed additional experiments to detect microfouling-coating interactions.

Design and develop a scalar covering

Existing research has shown how uniform, non-porous hydrogels with low swelling behavior require a polymer content of at least 40 wt%. To follow a similar manufacturing process, Schmid and colleagues chose to increase the polymer content of the coating to 50 wt.%, which negatively affected the adhesion and removal properties of the coating.

The results highlighted the excellent scale phobia of the coating. For example, the first crystallites were removed from the microtextured polymer almost immediately after flow began. From the start, the team removed a significant number of crystallites to achieve a nearly clean surface to highlight the scalophobicity properties of the designed coating under turbulent flow conditions.

Crystallite removal by shearing microtextured PED-DA 50 in a parallel plate flow chamber. (A) Schematic (not to scale) of the test section. The polymethyl methacrylate chamber is composed of a parallel plate channel connected to a fluidic system (tank, pump and flow meter), which provides turbulent shear flow in the channel (height a = 3 mm, width b = 12 mm , length l = 120 mm, hydraulic diameter DH = 4.8mm; Re = ρuDH/µ ≈ 6800; u ≈ 1.4 ms−1). (B) Experimental procedure showing, over time, t. Bottom view image sequence showing removal of calcium carbonate crystallites from microtextured PEG-DA 50 coating (C) (width w = 2 μm, height e = 2 μm, pitch p = 6 μm). Flow direction from left to right. (D) Magnified image sequence showing crystallite removal. Flow direction from left to right. Scale bars, (C) 200 μm and (D) 20 μm. Credit: Scientists progress (2023). DOI: 10.1126/sciadv.adj0324

Outlook

In this way, Julian Schmid and his team incorporated theories of adhesion and interfacial fluidics to develop a method to study the underlying physics of adhesion and microfouling removal on technical materials. They developed this technique based on a previously established method for analyzing antifouling materials to improve the approach to studying antifouling.

The method provided a better understanding of the dynamics of the complete coating behavior. The results revealed the interactions between dirt, substrates, and water to remove crystallites adhering to the surface under flow conditions. The team explored the versatility of antifouling materials and how design strategies varied depending on the dominant fouling mechanism.

For example, under particulate fouling, rigid coating surfaces performed well, while soft coatings outperformed under crystallization fouling. The hydrogels, on the other hand, had a low polymer content and therefore exhibited excellent microfouling and crystallite removal performance. For nonporous and hydrophilic hydrogels, the polymer content had to be increased, which Schmid and his team mitigated by microtexturing the surface.

Materials scientists have made intrinsically scalar surfaces and microtextured soft hydrogels to eliminate predominant regions of crystallites. The results provide significant details for the design of antifouling and scalar surfaces for research on adhesion and interfacial transport under heat transfer and flow conditions.

More information:

Julian Schmid et al, Immarting scalephobicity with rational microtexturing of soft materials, Scientists progress (2023). DOI: 10.1126/sciadv.adj0324

© 2024 Science X Network

Quote: Microtexturing of flexible materials to remove aqueous microfouling (January 5, 2024) retrieved on January 6, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.