Block copolymer micelles with well-defined core–shell structures significantly improve dye solubilization compared to random copolymers. This discovery may lead to more efficient and cost-effective micelles for the ink and dye industries as well as drug delivery systems in the pharmaceutical industries. Credit: Reproduced from Masahiko Asada, Hidenori Otsuka et al. courtesy of the Royal Society of Chemistry

Micelles are spherical molecular structures typically formed by block-structured amphiphilic molecules, which contain both hydrophilic and hydrophobic parts. The hydrophobic tails of these molecules come together to form a core, while the hydrophilic heads face outward, creating a protective shell. This structure allows micelles to encapsulate hydrophobic substances in their core and disperse them in an aqueous environment.

An example of micelles in action is soap, which traps dirt and oil, making them easy to rinse away with water. Micelles can be created using block copolymers, which have distinct hydrophilic and hydrophobic segments, or random copolymers with a mixed distribution of hydrophilic and hydrophobic segments. The former, used in the pharmaceutical industry, offers precise control of micelle properties but is more complex and more expensive to produce, while the latter, used in the dye industry, is simpler and cheaper to produce .

Researchers led by Mr Masahiko Asada and Professor Hidenori Otsuka from Tokyo University of Science (TUS) and DIC Corporation are investigating how to make micelles more effective at dissolving dyes. In a study presented on the cover of the journal Soft materialthey compared the performance of block copolymers and random copolymers to determine the most optimal micelle for dye dispersion.

“There is a trade-off between the use of random copolymers as dispersants for ink production and their inadequate dispersion performance. We studied block copolymer micelles and compared their dispersion performance with that of random copolymers to determine the structure micellar required for adequate solubilization of the dye,” explains Professor Otsuka, the lead author of the study.

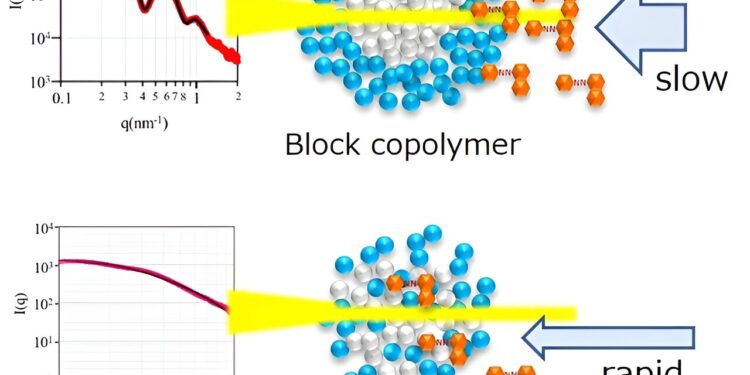

The researchers synthesized various block copolymers (BL01 to BL05) using different ratios of styrene (St), n-butyl methacrylate (BMA), and methacrylic acid (MA) as monomers. They compared the performance of these block copolymers with random copolymers (RD01, RD02, RD03 and RD04), made from styrene and methacrylic acid or acrylic acid. The copolymers and random copolymers were dispersed in water at a concentration of 0.5%, and the micellar structures were examined by small-angle X-ray scattering (SAXS) analysis.

SAXS results showed that micelles formed from block copolymers had a well-defined spherical structure with a clear core–shell boundary. Random copolymer micelles were found to have a more diffuse and continuous structure, resembling a random coil pattern without a distinct core–shell boundary. The lack of a clear core–shell structure in micelles formed from random copolymers reduces their ability to retain hydrophobic dyes.

In critical micelle concentration (CMC) tests, researchers measured the concentration at which micelles form by detecting changes in polarity around a pyrene fluorescent probe. The results showed that the block copolymer micelles had much lower polarity, meaning that the pyrene molecules were better protected inside the hydrophobic core of these micelles.

The researchers made similar observations by measuring the degree of solubilization of the hydrophobic orange oil dye SS in the micelles. Micelles made from random copolymers were found to easily penetrate the dye. However, BL01, BL03, and BL05 prevented the dye from penetrating the core, resulting in a longer time to reach saturation (2 days versus 10 hours for random copolymers).

Micelles (BL01, 03 and 05) with larger core volumes and more polymer molecules (higher aggregation numbers) retain or solubilize more dye (0.2 to 2 dye molecules per micelle) than the smaller micelles (BL02, BL04).

While larger micelles with well-defined core-shell structures took longer to become saturated with dye, they were able to contain a much higher amount of dye. The micelle with the highest dye solubilization was BL02. Its shell contained a random mixture of methacrylic acid (MA) and butyl methacrylate (BMA), which resulted in a highly polydisperse or varied interface between the core-shell and shell-solvent boundaries, allowing the dye to enter there. enter and be expelled quickly. .

Professor Otsuka explains: “The block copolymer micelles exhibited higher dye solubilization capacity, correlating with their core volume, clear core-shell contrast and slow solubilization rate. »

This discovery could lead to more efficient and cost-effective micelles for the ink and dye industries as well as the pharmaceutical industry.

More information:

Masahiko Asada et al, Study of the effect of micellar structures of block and random copolymers on the solubilization of dyes, Soft material (2024). DOI: 10.1039/D4SM00009A

Provided by Tokyo University of Science

Quote: Making micelles more efficient for dispersing dyes and drugs through well-defined core-shell structures (October 9, 2024) retrieved October 9, 2024 from

This document is subject to copyright. Except for fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.