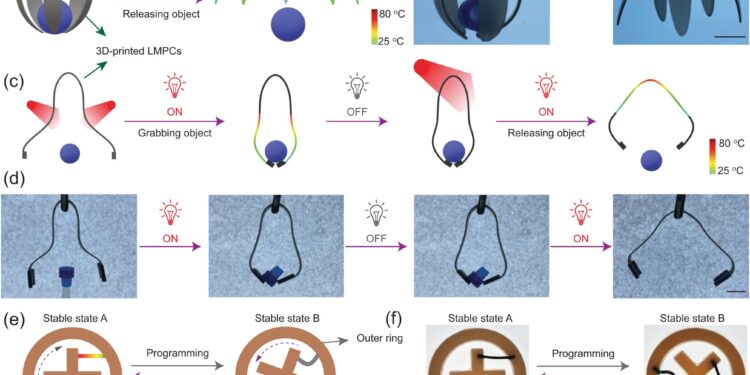

Application of 3D printed LMPCs as near-infrared (NIR) sensitive soft robots. a The diagram and (b) demonstration of object release via NIR light-sensitive LMPCs. Scale bar corresponds to 10 mm (c) Schematic and (d) demonstration of grasping and releasing an object via the use of NIR light-controlled LMPCs. The scale bar corresponds to 10 mm (e). The diagram and (f) demonstration of the rotated structure (state B) transforms into the original form (state A) upon NIR exposure. The scale bar corresponds to 5 mm. Credit: Natural communications (2023). DOI: 10.1038/s41467-023-43667-4

Researchers at the University of Queensland (UQ) are developing new 4D printing technology that produces shape-changing liquid metals for soft robotics.

4D printing is an extension of 3D printing, where solid objects are created using materials that can change shape when exposed to certain stimuli like heat, water or light.

At UQ’s Australian Institute of Bioengineering and Nanotechnology (AIBN), researchers are printing 4D structures using new liquid metal polymers that can be made to perform a range of mechanical tasks with infrared lasers.

Lead researchers Dr. Liwen Zhang and Dr. Ruirui Qiao said the unique preparation methods developed by their lab allow them to produce strong, durable 4D designs while being able to bend, grip, lift and release objects five times their weight. or return to a pre-programmed form.

“4D printing takes traditional 3D printing and adds a new dimension: the dimension of time,” said Dr. Zhang. “Our method allows us to produce smart liquid metals that can be customized, shaped and modified over time without the need for wires or circuitry.

“This is a new era for robotic applications and a turning point for additive manufacturing.”

4D printed objects are usually prepared with a 3D printer using specific ingredients that give the finished product new qualities and capabilities.

In their article published in the journal Natural communicationsDr Zhang, Dr Qiao and their colleague Professor Tom Davis detail how they used spherical liquid metal nanoparticles to prepare printing resins that respond to near-infrared light, meaning lasers can be used to guide materials for bending, grasping and grasping. release elements.

Although the technology is in its infancy, Dr Qiao believes there is great potential to use it in the design of soft robots, or technologies that mimic natural movements and interactions.

This could mean a number of applications in the aeronautical engineering and medical device sector, including coronary stents, artificial muscles and other devices that adapt and change shape inside the body.

More broadly, Dr Qiao said the ability to customize and shape materials after they are printed would lead to industrial breakthroughs and broader consumer innovations, from climate-responsive clothing and building materials to furniture to assemble yourself.

UQ researchers are printing 4D structures that can be made to carry out a range of mechanical tasks with infrared lasers. Credit: Australian Institute of Bioengineering and Nanotechnology, University of Queensland

“4D printing is a rapidly evolving field that is limited only by imagination,” said Dr. Qiao.

“The specific nanoparticles we use allow our materials to respond to lasers. Other 4D printed materials contain ingredients that react to water, heat, acid, electrical or magnetic energy.

“The early signs of this technology are incredibly promising and the wide range of potential applications encourages us to continue our research.”

More information:

Liwen Zhang et al, 3D Printed Liquid Metal Polymer Composites as NIR Sensitive 4D Printing Soft Robot, Natural communications (2023). DOI: 10.1038/s41467-023-43667-4

Provided by the Australian Institute of Bioengineering and Nanotechnology (AIBN)

Quote: Laser-controlled liquid metals herald a new era for soft robotics (January 11, 2024) retrieved January 11, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.