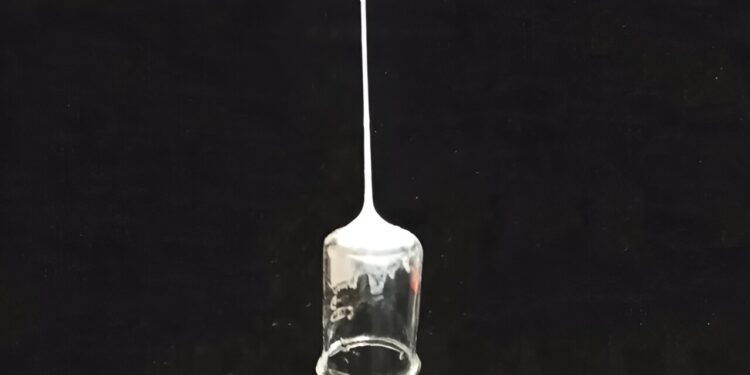

The liquid stream of silk solution solidifies into a fiber, adheres, and lifts a glass laboratory beaker. Credit: Marco Lo Presti, Tufts University

Every kid who’s read a comic book or watched a Spider-Man movie has tried to imagine what it would be like to shoot a spider web from their wrist, fly through the streets, and corner bad guys. Researchers at Tufts University took these imaginary scenes seriously and created the first web-throwing technology in which a fluid material can be thrown from a needle, immediately solidify as a string, then adhere and lift objects.

The study is published in the journal Advanced functional materials.

These sticky fibers, created at Tufts University’s Silklab, come from silk butterfly cocoons, which are boiled in a solution and broken down into their constituent proteins called fibroin. Silk fibroin solution can be extruded through narrow bore needles to form a stream which, with the right additives, solidifies into fiber when exposed to air.

Of course, nature is the original inspiration for deploying silk fibers into tethers, webs and cocoons. Spiders, ants, wasps, bees, butterflies, moths, beetles and even flies can produce silk at some point in their life cycle.

Nature has also inspired Silklab to pioneer the use of silk fibroin to make powerful glues that can work underwater, printable sensors that can be applied to virtually any surface, edible coatings that can extend life product conservation, a light-harvesting material that could significantly improve the efficiency of solar cells and more sustainable microchip manufacturing methods

However, while they have made significant progress with silk-based materials, researchers have yet to replicate the mastery of spiders’ ability to control the stiffness, elasticity, and adhesive properties of the threads they spin.

A breakthrough happened purely by chance. “I was working on a project making extremely strong silk fibroin adhesives, and while I was cleaning my glassware with acetone, I noticed that a web-like material was forming at the bottom of the glass,” said Marco Lo Presti, research assistant professor at Touffes.

This accidental discovery overcame several technical challenges related to spider thread replication. Silk fibroin solutions can slowly form a semi-solid hydrogel over a period of several hours when exposed to organic solvents like ethanol or acetone, but the presence of dopamine, used in the manufacture of adhesives , allowed the solidification process to occur almost immediately.

When the organic solvent was mixed quickly, the silk solution quickly created fibers with high tensile strength and adhesion. Dopamine and its polymers use the same chemistry used by barnacles to form fibers that stick tenaciously to surfaces.

The next step was to spin the fibers in the air. The researchers added dopamine to the silk fibroin solution, which appears to speed up the transition from liquid to solid by drawing water away from the silk. When injected through a coaxial needle, a thin stream of silk solution is surrounded by a layer of acetone which triggers solidification.

Acetone evaporates into the air, leaving a fiber attached to any object it comes into contact with. Researchers enhanced the silk fibroin and dopamine solution with chitosan, a derivative of insect exoskeletons that gives the fibers up to 200 times greater tensile strength, and a borate buffer, which increases their adhesiveness about 18 times.

The diameter of the fibers could vary from that of a human hair to about half a millimeter, depending on the bore of the needle.

The device can project fibers capable of picking up objects weighing more than 80 times their own weight under various conditions. The researchers demonstrated this by picking up a cocoon, a steel bolt, a laboratory tube floating on water, a scalpel partially buried in the sand, and a block of wood from a distance of about 12 centimeters.

Lo Presti noted that “if you look at nature, you will find that spiders cannot cast their webs. They typically spin silk from their gland, make physical contact with a surface, and draw lines to construct their webs. way of pulling a fiber from a device and then attaching and picking up an object from a distance. Rather than presenting this work as bio-inspired material, it is actually superhero-inspired material.

Natural spider silk is still about 1,000 times stronger than the synthetic fibers studied in this study. But with a little more imagination and engineering, innovation will continue to improve and pave the way for a variety of technological applications.

“As scientists and engineers, we navigate the boundary between imagination and practice. That’s where all the magic happens,” said Fiorenzo Omenetto, Frank C. Doble Professor of Engineering at Tufts University and director of Silklab.

“We can take inspiration from nature. We can take inspiration from comic books and science fiction. In this case, we wanted to reverse engineer our silk fabric to make it behave the way nature does. originally designed it, and the comic book writers came up with it.”

More information:

Marco Lo Presti et al, Dynamic adhesive fibers for remote object capture, Advanced functional materials (2024). DOI: 10.1002/adfm.202414219

Provided by Tufts University

Quote: Inspired by Spider-Man, researchers recreate web-slinging technology (October 10, 2024) retrieved October 11, 2024 from

This document is subject to copyright. Except for fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.