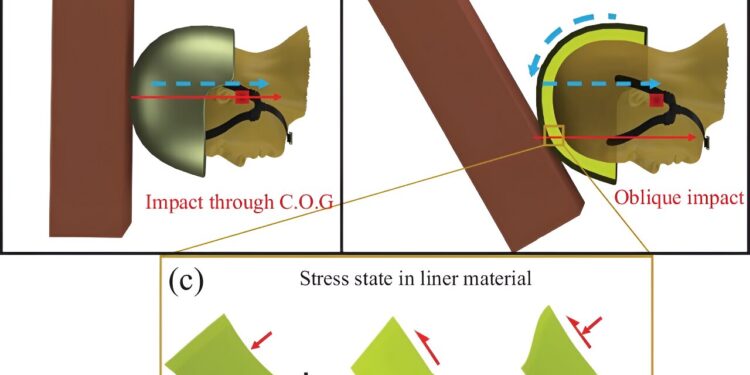

Helmet impact kinetics and induced deformations on the protective liner: (a) An impact that acts through the center of gravity of the head-helmet system causing pure linear acceleration, (b) An impact that moves away from the center of gravity of the head-helmet system causing both linear and rotational accelerations around the center of gravity, (c) The helmet liner is subjected to compressive and shear stresses simultaneously. Credit: Experimental mechanics (2023). DOI: 10.1007/s11340-023-01013-1

From falls to football tackles, most head hits happen at odd angles. And these impacts trigger simultaneous linear and rotational head movements. The rotational movement in particular causes shear stress, which is particularly damaging to the brain.

A new lightweight foam material could relieve the brain of most, if not all, of this tension.

Developed by engineers at the University of Wisconsin-Madison, the new material, a foam of vertically aligned carbon nanotubes, can dissipate a huge amount of rotational kinetic energy during an impact. And as a helmet liner material, it could mitigate or even prevent traumatic brain injury by weakening rotational kinetic energy before it reaches the brain.

In fact, the new material absorbs shear stress 30 times better than the foam currently used in the liners of U.S. military combat helmets. The team described the material and its unique properties in a paper published December 7, 2023 in the journal Experimental mechanics.

“This material shows great promise in enabling the creation of new helmets that are significantly more effective in preventing concussions,” says Ramathasan Thevamaran, an assistant professor of mechanical engineering at UW-Madison who led the research.

PhD student Bhanugoban Maheswaran tests vertically aligned carbon nanotube foams in Assistant Professor Ramathasan Thevamaran’s lab. Credit: Photo by Joel Hallberg

Why it works

Currently, some helmets attempt to reduce rotational movement due to impacts by employing a layer that allows sliding movement between the wearer’s head and the outer shell of the helmet. However, Thevamaran claims that these moving layers do not dissipate energy due to shear stress; Worse still, they tend to get stuck when strongly compressed, i.e. following a blow.

Since it does not rely on sliding layers, the new material avoids these drawbacks.

Better yet, when compressed, the material adapts particularly better to shear and dissipates the energy of an impact, Thevamaran explains.

This advancement builds on his previous research into vertically aligned carbon nanotube foams, in which his team demonstrated the material’s extraordinary shock absorption capabilities. The material is made of carbon nanotubes – cylinders of carbon just one atom thick in each layer – carefully arranged into tight cylindrical structures. The novel architecture of the material, which exhibits unique structural characteristics across multiple length scales, gives the material its exceptional properties.

Additionally, the researchers recently demonstrated that their vertically aligned carbon nanotube foams exhibited exceptional thermal conductivity and diffusivity, which would enable a helmet liner made of this material to keep the user’s head cool in hot environments.

Combined with its thinness, this cooling capacity puts the new material on par with graphite foams and makes it attractive for applications where less weight is important. Beyond helmet liners, the material could also be used in electronic packaging and electronic systems to protect against impact and keep electronic devices cool.

More information:

B. Maheswaran et al, Mitigating oblique impacts by untangling looped carbon nanotubes in helmet liners, Experimental mechanics (2023). DOI: 10.1007/s11340-023-01013-1

Provided by University of Wisconsin-Madison

Quote: In a bid to prevent debilitating head injuries, new foam material hits the top (December 27, 2023) retrieved December 27, 2023 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.