Principles of rational design of relaxer antiferroelectric materials. Credit: IMR

A research team led by Professor Hu Weijin of the Institute of Metals Research (IMR) of the Chinese Academy of Sciences (CAS), in collaboration with partners, has developed a one-second manufacturing method for wafer-scale energy storage capacitors that achieves astonishing heating and cooling rates of up to 1,000°C per second.

The work, published on November 15 in Scientific advancesintroduces a rapid “flash annealing” technique and opens a new path for manufacturing the next generation of high-performance energy storage capacitors.

Dielectric energy storage capacitors play an indispensable role in critical power electronic devices, from pulsed lasers to electric vehicles, because they can charge and discharge quickly while withstanding extreme operating conditions. However, scientists have long grappled with the fundamental challenge of developing capacitors that can provide high energy storage capacity, withstand temperature extremes in both extreme heat and intense cold, and remain suitable for mass production.

Traditional manufacturing methods often rely on chemical doping, multiphase composition, or the deliberate introduction of structural defects to engineer materials with specific microstructures. These processes are complex and time-consuming, hampering the scalable production of high-performance dielectric films.

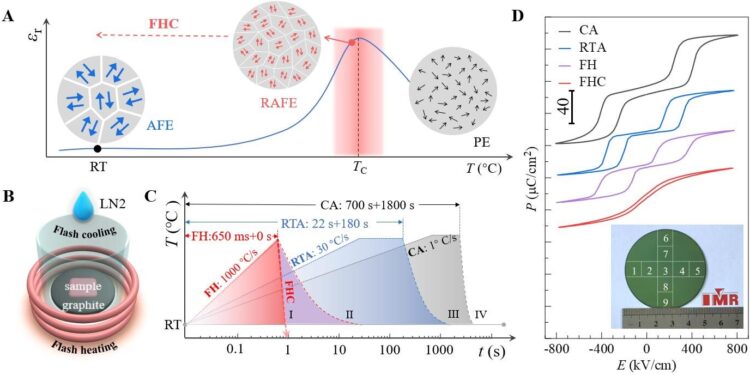

The new “flash annealing” method overcomes these limitations by achieving heating and cooling rates of up to 1,000°C per second, enabling the synthesis of a relaxed antiferroelectric lead zirconate film on a silicon wafer in just one second.

So, what’s the magic behind this one-second “ice fire” forge?

According to the researchers, this technique effectively “freezes” the high-temperature paraelectric phase structure of the material at room temperature, creating nanodomains smaller than 3 nanometers. These tiny structures act like a complex maze, which is essential for triggering high-performance relaxing antiferroelectric behavior and enabling highly efficient energy storage. At the same time, the flash annealing process produces a denser and more uniform film texture and effectively suppresses the evaporation of volatile lead elements.

Together, these improvements allow the film to withstand extremely high electric fields while achieving strong polarization, ultimately increasing the energy storage density of the capacitor to 63.5 J/cm³.

Even more impressive is the exceptional thermal stability demonstrated by capacitors produced using this method. Tests show that after thermal cycling from extreme cold of -196°C (liquid nitrogen temperature) to scorching temperatures of up to 400°C, degradation in energy storage density and efficiency remains minimal: less than 3%. Thus, the capacitor can operate reliably in environments ranging from the icy vacuum of space to the high temperature conditions of an underground oil exploration well.

This technology is also simple to implement and scalable. The team has already produced uniform, high-performance films on two-inch silicon wafers, providing a viable industrial path to on-chip energy storage solutions.

More information:

Yizhuo Li et al, Flash annealing – wafer-scale relaxing antiferroelectrics for enhanced energy storage performance, Scientific advances (2025). DOI: 10.1126/sciadv.ady2349

Provided by the Chinese Academy of Sciences

Quote: “Ice-fire” forge makes wafer-scale energy storage capacitors in just one second (November 18, 2025) retrieved November 18, 2025 from

This document is subject to copyright. Except for fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.