Credit: Joule (2024). DOI: 10.1016/j.joule.2023.12.022

A Cornell Engineering team has created a new lithium battery capable of charging in less than five minutes, faster than any battery of its type on the market, while maintaining stable performance over extended charge cycles and discharge.

The advance could ease “range anxiety” among drivers who worry that electric vehicles won’t be able to travel long distances without time-consuming charging.

“Range anxiety is a bigger barrier to electrification in transportation than any other barrier, like battery cost and capacity, and we’ve identified a way to eliminate it using rational electrode designs,” said Lynden Archer of Cornell’s James A. Friend. Professor Emeritus of Engineering and Dean of Cornell Engineering, who oversaw the project. “If you can charge an electric vehicle battery in five minutes, I mean, hell, you don’t need a battery big enough for 300 miles of range. You can get by with less, which could reduce the cost of electric vehicles, allowing for wider adoption.

The team’s paper, “Fast-Charge, Long-Duration Storage in Lithium Batteries,” published January 16 in Joule. The lead author is Shuo Jin, a doctoral student in chemical and biomolecular engineering.

Lithium-ion batteries are among the most popular ways to power electric vehicles and smartphones. Batteries are lightweight, reliable and relatively energy efficient. However, they take hours to charge and do not have the capacity to handle large power surges.

“Our goal was to create battery electrode designs that charge and discharge in a way that aligns with daily routine,” Jin said. “In practical terms, we want our electronic devices to charge quickly and operate for long periods of time. To achieve this, we have identified a unique indium anode material that can be effectively combined with various cathode materials to create a battery which charges quickly and discharges slowly.”

Archer’s lab had previously approached battery design by focusing on how ions move in electrolytes and crystallize at metal anode interfaces, then used that knowledge to manipulate electrode morphology to make safer anodes for long-term storage.

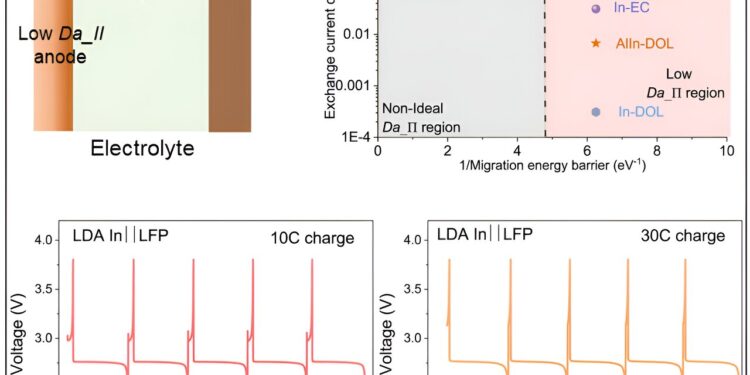

For their new lithium battery, the researchers took a different approach and focused on the kinetics of electrochemical reactions, specifically using a chemical engineering concept called the “Damköhler number.” It is essentially a measure of the rate at which chemical reactions occur, relative to the rate at which the material is transported to the reaction site.

The identification of battery electrode materials exhibiting intrinsically fast solid-state transport rates, and therefore low Damköhler numbers, helped researchers identify indium as an exceptionally promising material for charge batteries. fast. Indium is a soft metal, primarily used to make indium tin oxide coatings for touch screens and solar panels. It is also used to replace lead in low temperature solders.

The new study shows that indium has two crucial characteristics as a battery anode: an extremely low migration energy barrier, which sets the rate at which ions diffuse in the solid state; and a modest exchange current density, related to the rate at which ions are reduced in the anode. The combination of these qualities (rapid diffusion and slow surface reaction kinetics) is essential for rapid charging and long-term storage.

“The key innovation is that we have discovered a design principle that allows the metal ions of a battery anode to move freely, find the right configuration and only then participate in the charge storage reaction,” he said. Archer said. “The end result is that with each charge cycle, the electrode is in a stable morphological state. This is precisely what gives our new fast-charging batteries the ability to repeatedly charge and discharge over thousands of cycles.”

This technology, combined with wireless inductive charging on roads, would reduce the size – and cost – of batteries, making electric transportation a more viable option for drivers.

However, this does not mean that indium anodes are perfect, or even practical.

“While this result is exciting, as it teaches us how to charge batteries quickly, indium is heavy,” Archer said. “This is an opportunity for computational chemical modeling, perhaps using generative AI tools, to learn what other lightweight material chemistries could achieve the same inherently low Damköhler numbers. For example, are there- there are metallic alloys that we have never studied, which have “

Co-authors include Yong Joo, professor in the Robert Frederick Smith School of Chemical and Biomolecular Engineering; Rong Yang, assistant professor at the Smith School; and doctoral students Xiaosi Gao, Shifeng Hong, Yue Deng and Pengyu Chen.

More information:

Shuo Jin et al, Fast charging and long-term storage in lithium batteries, Joule (2024). DOI: 10.1016/j.joule.2023.12.022

Joule

Provided by Cornell University

Quote: Fast-charging lithium battery seeks to eliminate “range anxiety” (January 22, 2024) retrieved January 22, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.