Synthesis of large -scale graphics on CU with low cost. Credit: Jian Hao et al

Capture carbon dioxide (Co2) Industrial emissions are crucial in the fight against climate change. But current methods, such as chemical absorption, are costly and high energy intensity. Scientists have long been in the eyes – an ultra -sure and thin material of the atom – as a promising alternative for the separation of gases, but the manufacture of graphene membranes with large region has been a challenge.

Now, an EPFL team, led by Professor Kumar Agrawal, has developed an evolutionary technique to create porous graphene membranes that selectively filter the CO2 Gas mixtures. Their approach reduces production costs while improving the quality and performance of membranes, paving the way for real applications in carbon capture and beyond.

The study was published in Chemical genius of nature.

The graphene membranes are excellent to separate the gases because they can be designed with just size pores to leave Co2 Through while blocking larger molecules like nitrogen. It makes them ideal to capture the CO2 Emissions from power plants and industrial processes. But there is a socket: making these membranes on a significant scale has been difficult and costly.

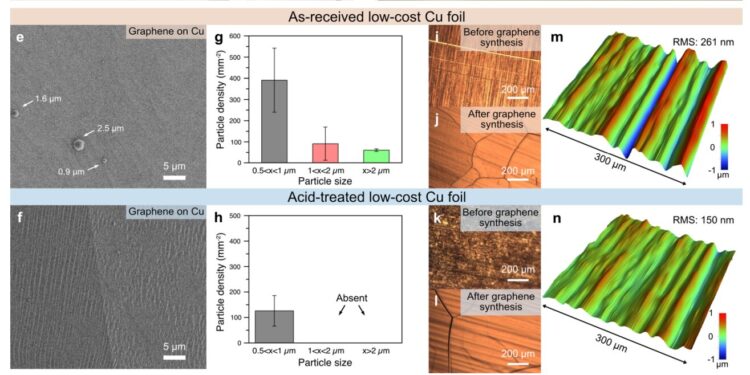

Most existing methods are based on costly copper sheets to cultivate high -quality graphene necessary for membranes and require delicate handling techniques that often introduce cracks, reducing the effectiveness of the membrane. The challenge was to find a way to create large high quality graphene membranes in a profitable and reproducible way.

The EPFL team has taken up these challenges head -on. First of all, they developed a method to develop high quality graphene on low -cost copper sheets, considerably reducing materials expenses. Then, they refined a chemical process using ozone (O₃) to climb tiny pores in the graphene, allowing a highly selective CO2 filtration.

Above all, they have improved the way in which gas interacts with graphene, guaranteeing the uniform training of pores in large areas – a key step towards industrial scalability.

To solve the problem of the fragility of the membrane, the researchers also introduced a new transfer technique. Instead of floating the delicate graphene film on a support, which often leads to cracks, they have designed a direct transfer process inside the membrane module which eliminates manipulation problems and reduces failure rates to zero.

Using their new approach, researchers have successfully created graphene membranes of 50 cm² – larger than what was previously possible – with an almost perfect integrity. The membranes have demonstrated an exceptional CO2 selectivity and high gas permeance, which means that they effectively allow2 through while blocking unwanted gases.

In addition, by optimizing the oxidation process, they were able to increase the density of the CO2-selective, further improving performance. Calculation simulations have confirmed that improving gas flow through the membrane played a crucial role in the achievement of these results.

This breakthrough could change the game to capture carbon. Traditional co2 Capture technologies are based on chemical processes with high energy intensity, which makes them complex and expensive for general use. Grave membranes, on the other hand, require no heat supply and operate using simple filtration driven by pressure, considerably reducing energy consumption.

Beyond capture carbon, this method could be applied to other gas separation needs, including hydrogen purification and oxygen production. With its evolutionary production process and profitable materials, EPFL innovation brings the graphene membranes to commercial viability.

More information:

Jian Hao et al, evolving synthesis of the CO₂ selective monocouche graphene membranes. Chemical genius of nature (2025). DOI: 10.1038 / S44286-025-00203-Z. www.nature.com/articles/S44286-025-00203-Z

Supplied by Federal Polytechnic School of Lausanne

Quote: Evolutionary graphene membranes could overeat carbon capture (2025, April 11) recovered on April 11, 2025

This document is subject to copyright. In addition to any fair program for private or research purposes, no part can be reproduced without written authorization. The content is provided only for information purposes.