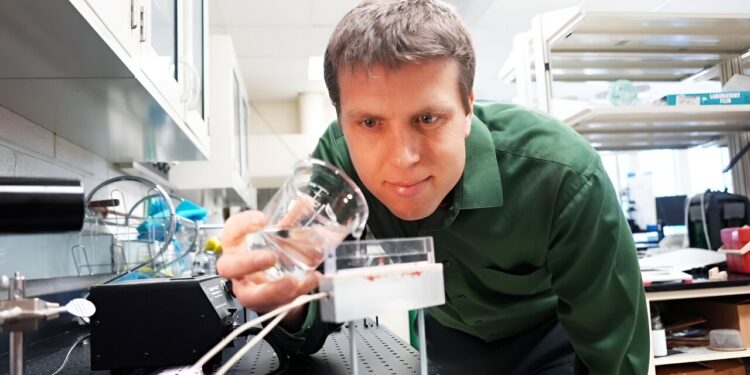

Jonathan Boreyko pours water into the boiler his team created to make jumping bubbles. Credit: Alex Parrish for Virginia Tech.

Water is often the preferred resource for heat transfer, being used in large-scale cooling operations such as data centers that power the Internet and nuclear power plants that power cities. Discovering dynamic phenomena to make water-based heat transfer more energetic and cost-effective is the ongoing work of Jonathan Boreyko, associate professor and John R. Jones III scholar in mechanical engineering.

Boreyko and his team have published numerous papers on the topic of water and how it can move, with members of his Nature-Inspired Fluids and Interfaces Lab producing bouncing water droplets propelled by surface tension and frost which jumps electrostatically. After incorporating the two liquid and solid phases in the first two volumes, their third volume studies a third phase with boiling water.

“During my doctoral research at Duke University, I discovered jumping water droplets,” Boreyko said. “A decade later, my own graduate student discovered jumping ice during his research on gel growth. This determined me to complete a three-phase ‘trilogy’ for jumping water, which we we achieved here with this article about jumping bubbles while boiling water.” When Hyunggon showed me the first videos of these jumping bubbles that complete the trilogy, needless to say, I was jumping with excitement. ”

Graduate student Hyunggon Park created a microstructured boiler capable of releasing bubbles ten times smaller than usual, deploying a constant barrage of bubbles to transport energy. The result is a more efficient method of removing heat from a surface. The study is published in Advanced functional materials.

Lean on the boil

Boiling is the most efficient way to continually transfer heat into water. If the boiling remains constant, so does the energy flow. Energy is transported in bubbles, like spherical cars carrying thermal passengers. These bubbles normally leave when their own buoyancy becomes stronger than the surface’s adhesion, causing them to rise to the surface and release energy.

Park and Boreyko’s new method improves on this principle by making the bubble car fleet smaller and more numerous. Because there is a more constant departure of bubbles, more energetic passengers also leave. The bubbles do not wait for their own buoyancy to do the work, but they move away from the heated surface more quickly. Since the bubbles are also microscopically small, the team fixed a fault that occurs with larger bubbles and blocks heat removal.

“Normally, buoyancy detaches these surface bubbles when they are a few millimeters in diameter, allowing them to escape and release heat as vapor,” Boreyko explained. “When boiling at higher temperatures, these large surface bubbles coalesce to form a continuous vapor film. This film insulates the liquid from the hot surface, causing a breakdown in heat transfer.”

Surface Level Engineering

The secret to the team’s method lies in the technical surfaces they created. By making a set of micro-cavities on the boiling surface, bubbles form and grow preferentially inside the cavities. Pairs of cavities are intentionally placed very close together, causing neighboring bubbles of unusually small sizes to merge. At such small sizes, the force of surface tension is very strong, causing the bubbles to move away from the surface as they merge. In the case of a data center, faster removal of heat from a surface could mean the difference between business as usual and costly downtime.

In many ways, this jumping bubble effect is very similar to the jumping dew droplets previously discovered by Boreyko. Using surface tension proved useful in both cases, but the added factor of heat introduces a new dynamic.

Putting these pieces together, Boreyko expects the jumping phenomenon to be more practical when it finds widespread applications for cooling and heat transfer.

“To blow up the droplets, the surface needs a hydrophobic coating and ultra-small nanostructures, both of which are fragile and expensive,” says Boreyko. “In contrast, bubbles prefer to jump on a hydrophilic surface, which allows the use of uncoated metals. Additionally, the microcavities needed for bubbles to jump are much larger and more durable than the nanostructures needed for droplets to jump. ”

This project lays a deeper foundation for understanding the fluid mechanics of the jumping bubble effect. The next step is to measure the heat transfer enhancement through boiling, mapped over a wide range of temperatures and surface geometries, to better understand the full potential of enhanced jump boiling.

More information:

Hyunggon Park et al, Coalescence-induced jumping bubbles during pool boiling, Advanced functional materials (2023). DOI: 10.1002/adfm.202312088

Provided by Virginia Tech

Quote: Artificial surface helps boiled bubbles jump to carry more heat (2023, December 4) retrieved December 4, 2023 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.