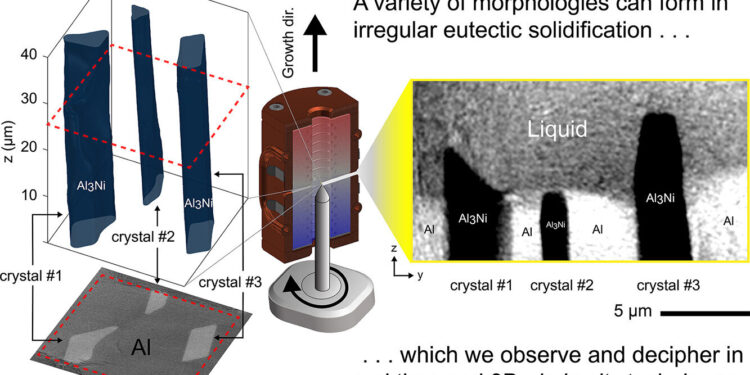

Credit: Acta Materialia (2024). DOI: 10.1016/j.actamat.2024.120314

During eutectic solidification, a mixture of two or more solids self-assembles, forming composite microstructures ranging from ordered layers to complex, maze-like patterns that underlie properties such as tensile strength or ductility.

Until now, researchers have not understood what conditions cause eutectics to form certain patterns, which is essential for designing reproducible next-generation eutectic composites.

Real-time capture of the solidification of an aluminum-nickel eutectic alloy (Al-Al3Ni) at nanometer resolution revealed that increasing the solidification rate shifts the microstructure from irregular and faceted to regular and rounded, according to a study by researchers at the University of Michigan recently published in Acta Materialia.

Exploiting this new understanding of eutectic formation will help tune the microstructure of the class of materials used in high-temperature components of turbines or reactors.

“I have always been fascinated by patterns in nature, like snowflakes, no two of which are ever the same.

“This fascination with how seemingly simple processes can give rise to infinitely rich, complex and unique structures drives me to explore the underlying principles behind them,” said Ashwin Shahani, associate professor of materials science and engineering and chemical engineering at UM and senior author of the study.

“In materials science, the same kind of wonder applies: how can small changes in conditions lead to radically different microstructures?”

To better understand how eutectic microstructures form, the research team designed a new in situ furnace at the synchrotron beamline for directional solidification, a technique in which crystal growth from the liquid phase to the solid phase is oriented in a specific direction. The device allows precise control of the solidification process space, enabling detailed study of pattern formation during eutectic solidification.

To correlate nanoscale observations with microscale phenomena, the researchers combined two visualization techniques. Optical microscopy captured solidification over large spatial and temporal scales, while synchrotron transmission X-ray microscopy provided nanoscale information. The latter was performed at the 18-ID full-field X-ray imaging beamline at Brookhaven National Laboratory’s National Synchrotron Light Source II.

With this, they directly observed the interaction between the liquid, aluminum (Al) and nickel aluminide (Al3Ni) crystals during solidification under different conditions. The growth rate of Al3Ni compared to Al—called the coupling degree—determined the shape of the solid microstructures left behind.

For example, when solidifying at lower speeds, the main tips of the Al3Ni grows before Al, causing irregular, faceted growth. At high solidification rates, Al3Ni and Al grow at the same rate, resulting in rounded, even growth.

In a casting, the rate of solidification depends on several factors, including the thermal conductivity of the melt and the rate of heat extraction.

“Our novel experiments and real-time observations help explain the wide variety of patterns produced by the solidification of eutectics containing rigid intermetallic phases. This information is essential to inform and validate materials synthesis simulations,” said Paul Chao, a UM PhD in materials science and engineering who spent a full year in 2022 as a resident scientist embedded at the synchrotron beamline, and first author of the study.

“Our experiences serve as an example of how excellent mentorship at the University of Michigan, partnership with Brookhaven National Laboratory, and international collaboration are essential to cutting-edge research that can solve fundamental scientific puzzles.”

This discovery is of great relevance to a broad spectrum of eutectic systems, including metallic, semimetallic, and organic ones.

“Manipulating these models is more than just a technical activity: it is a way to discover fundamental principles and apply them in meaningful ways, from improving the strength of materials to developing new approaches in materials design,” Shahani said.

More information:

Paul Chao et al, From irregular eutectic growth to regular eutectic growth in the Al-Al model3Ni system: In situ observations during directional solidification, Acta Materialia (2024). DOI: 10.1016/j.actamat.2024.120314. On arXiv: DOI: 10.48550/arxiv.2408.14346

Provided by the University of Michigan College of Engineering

Quote:Deciphering the Fundamentals of Eutectic Solidification Using Real-Time Imaging at the Nanoscale (2024, September 9) retrieved September 9, 2024 from

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without written permission. The content is provided for informational purposes only.