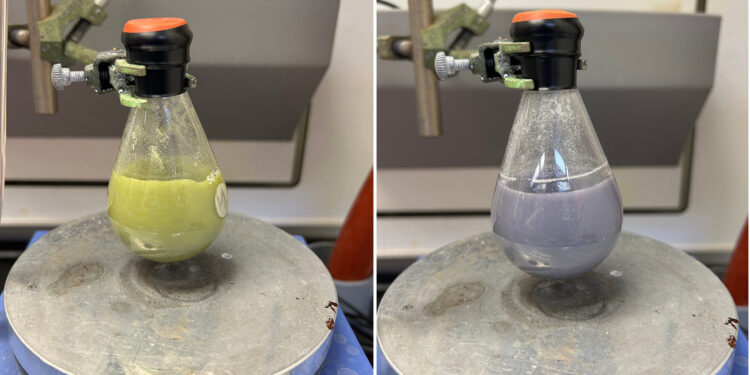

Different steps in a chemical reaction with the reagent samarium diiodide. The vial on the left contains a yellow, inactive form of the compound. Over time, the compound becomes active and turns purple, as seen on the right. This color change occurs because the oxidation state of the samarium reagent changes from 3+ to 2+, or from Sm(III) to Sm(II), meaning it gains an electron. Credit: Caltech/Chungkeun Shin

The metallic element samarium, when bonded to other elements, is an incredibly useful chemical reagent for synthesizing molecules that can lead to new pharmaceuticals. Discovered in a Russian mine in 1879, the element is named after the mineral in which it was found, called samarskite, itself named after Russian mining engineer Vasily Samarsky-Bykhovets.

The most common samarium reagent is samarium diiodide, which consists of one atom of samarium and two atoms of the element iodine.

But producing the versatile reagent in quantities large enough to be used in industrial settings has proven difficult. “The reagent is sensitive to air, so you often have to make the solution fresh, just before the reaction,” says Caltech graduate student Chungkeun Shin, who works in the lab of Sarah Reisman, the Bren Professor of Chemistry and the Norman Davidson Leadership Chair in Caltech’s Division of Chemistry and Chemical Engineering.

“And we often have to use large amounts of it, even in small reactions, which is not practical for running reactions on an industrial scale.”

As reported in the August 22 issue of the newspaper ScienceCaltech chemists have managed to solve this scaling conundrum. The study is titled “Sm-enabled samarium reductive (electro)catalysisIII-protonolysis of alkoxides.”

Their solution allows the samarium iodide reagent to recycle itself for repeated use in a single reaction, meaning that large amounts of solvents and new preparations are no longer required.

“Samarium diiodide is used in academia to synthesize natural products like taxol, an anticancer agent, but it’s not practical to create products like this on an industrial scale,” Reisman says. “The breakthrough is that we can now translate some of these interesting reactions into process development or discovery.”

The samarium reagent has been limited to laboratory use due to a troublesome samarium-oxygen bond that forms during reactions and renders the chemical inactive.

“Until now, it’s been very difficult to recycle samarium back to its active state,” says Caltech graduate student Emily Boyd, who works in the lab of Jonas Peters, the Bren Professor of Chemistry and director of the Resnick Sustainability Institute at Caltech. Boyd and Shin are co-senior authors of the new study.

“The reagent often ends up with a very strong samarium-oxygen bond that is difficult to break and makes it difficult to recycle the reagent,” she explains.

In other words, the oxygen bond leads to a dead end for the reaction. “It’s like the samarium reagent gets lazy, sits on a couch and doesn’t want to work,” Shin says.

“It’s very comfortable in that state and wants to stay that way,” Boyd says. “So we experimented with different acids to break the samarium-oxygen bond and get the reagent back to work.”

Previous attempts to break this samarium-oxygen bond have required the use of harsh chemicals. In the new study, the researchers were able to break the bond using a mild acid, which is more practical for large-scale reactions. The acid provides a proton to the bound oxygen, which turns it into an alcohol and releases the samarium.

Boyd said she and her colleagues in the Peters lab were interested in working with the Reisman lab because their research studies on nitrogen fixation involve the agent samarium diiodide.

Nitrogen fixation is the process by which nitrogen gas in our atmosphere is converted into compounds such as ammonia that are essential to plants (and the people who eat them). This process can be done naturally by bacteria, and artificially by chemical reactions. The Peters lab is developing new chemical reactions to artificially fix nitrogen more efficiently and sustainably than is commonly used today.

“Our lab is very interested in the conversion of nitrogen to ammonia,” Boyd says. “We use the samarium reagent to study these reactions, but it would be impossible to scale it up to industrial scale. After talking to the Reisman group, which specializes in synthetic organic chemistry, we decided to join forces.”

The collaboration proved synergistic. Shin explains, “I don’t have Emily’s skills and vice versa. This combination allowed us to understand this difficult alchemy.”

More information:

Emily A. Boyd et al., Sm-activated samarium reductive (electro)catalysisIII -protonolysis of alkoxides, Science (2024). DOI: 10.1126/science.adp5777

Provided by California Institute of Technology

Quote:Chemists successfully scale up common reagent for industrial-level applications (2024, August 23) retrieved August 24, 2024 from

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without written permission. The content is provided for informational purposes only.