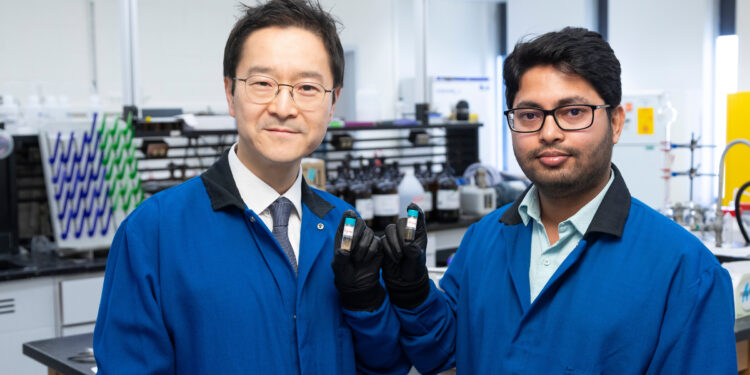

Hoyong Chung, an associate professor in the FAMU-FSU College of Engineering, and postdoctoral researcher Arijit Ghorai have developed a new biomass-based material that can be used to repeatedly capture and release carbon dioxide. Credit: Scott Holstein/FAMU-FSU College of Engineering

A new biomass-based material developed by FAMU-FSU College of Engineering researchers can be used to repeatedly capture and release carbon dioxide.

The material is mainly composed of lignin, an organic molecule that is a main component of wood and other plants, and it can absorb carbon dioxide (CO2) from concentrated sources or directly from the air. The search appears in Advanced materials.

“The beauty of this work lies in the ability to precisely control the capture and release of CO2 “We were able to produce materials without high pressure or extreme temperatures,” said Hoyong Chung, co-author of the study and associate professor in the FAMU-FSU College of Engineering. “Our tests showed that the structure of this material remained the same even after being used multiple times, making it a promising tool for reducing carbon emissions.”

In previous research, Chung’s team developed a lignin and CO2petroleum-based polymer that represented a potential alternative to traditional petroleum-based plastic. This paper expands on this research by showing the possibility of reversing the process and reusing the material to absorb CO2 again in the future.

Lignin is abundant in plants and is cheap. It is often harvested as a byproduct of wood processing. Scientists are working to find new ways to use this natural resource.

One gram of the material developed by Chung’s team captured 47 milligrams, or about 5 percent of the weight of the original material, of CO2 from a concentrated source and 26 milligrams from ambient air exposure. The absorbed CO2 can be permanently sequestered or released for use in various applications, such as manufacturing, agriculture, and others.

The researchers were surprised by the release mechanism. By analyzing a sample using nuclear magnetic resonance spectroscopy, they saw bubbles appear when the sample was heated.

“That piqued our curiosity,” Chung said. “What’s going on here? Why do we see these little bubbles every time we try to analyze this polymer?”

Further investigation revealed that the heat was causing the material to release CO.2The researchers studied the reaction and found that by controlling the heat applied to the sample, they were able to control the amount of CO2 released. They also showed the possibility of using this captured gas in other reactions.

A temperature of about 60 degrees Celsius at normal atmospheric pressure is enough to release CO2which means that high temperatures and pressures are not required for the reuse process. This CO2 The release temperature can be increased or decreased for different applications.

“It’s like a sponge for CO2“It absorbs energy, releases it and dries out so it can capture more,” Chung said. “It’s fascinating to see what you can do with this material.”

Postdoctoral researcher Arijit Ghorai was the study’s lead author.

More information:

Arijit Ghorai et al, Ionic lignin polymers for controlled capture, release and conversion of CO2 into high value chemicals, Advanced materials (2024). DOI: 10.1002/adma.202406610

Provided by Florida State University

Quote:Biomass-based polymer can capture and release CO₂ without high pressure or extreme temperatures (2024, August 26) retrieved August 26, 2024 from

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without written permission. The content is provided for informational purposes only.