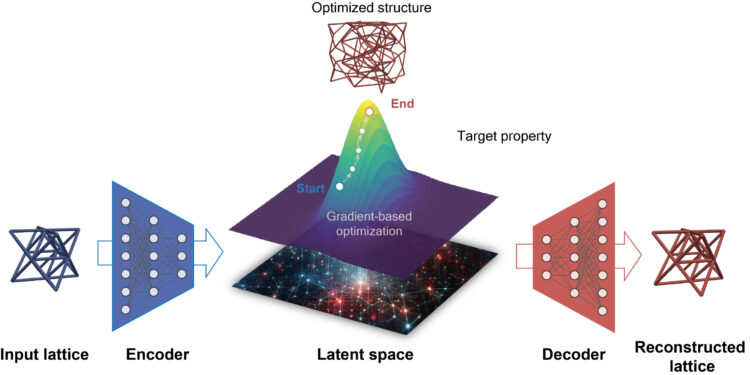

The structure of a metamaterial is encoded in an abstract space. Optimization effectively improves the design towards the desired properties. A decoder transforms the optimized design into an actual lattice structure. Credit: Illustration: ETH Zurich / Li Zheng

Bike helmets that absorb the energy of an impact, running shoes that give you an extra boost with every step, or implants that behave like natural bone. Metamaterials make such applications possible. Their internal structure is the result of a careful design process, following which 3D printers produce structures with optimized properties.

Researchers led by Dennis Kochmann, professor of mechanics and materials at the Department of Mechanical and Process Engineering at ETH Zurich, have developed new AI tools that bypass the tedious and intuitive design process of metamaterials. Instead, they predict metamaterials with extraordinary properties in a rapid and automated manner.

New, their framework applies to significant loads (known as non-linear), for example when a helmet absorbs significant forces during an impact.

Kochmann’s team was among the pioneers in designing small-scale cellular structures (similar to the arrays of beams in timber-framed homes) to create metamaterials with specific or extreme properties. “For example, we design metamaterials that behave like fluids: difficult to compress but easy to deform. Or metamaterials that shrink in all directions when compressed in a particular direction,” says Kochmann.

Efficient and optimal hardware design

The design possibilities seem endless. However, the full potential of metamaterials is far from being exploited, since the design process is based on experience, involving trial and error. Additionally, small changes in structure can give rise to huge changes in properties.

In their recent breakthrough, the researchers successfully used AI to systematically explore the abundant design and mechanical properties of two types of metamaterials. Their computational tools can predict optimal structures for desired deformation responses with the press of a button.

The key lies in using large datasets of the deformation behavior of real structures to train an AI model that not only reproduces the data, but also generates and optimizes new structures. Leveraging a method known as “variational autoencoders,” the AI learns the essential characteristics of a structure from the broad set of design parameters and how they result in specific properties.

It then uses this knowledge to generate a metamaterial model whenever researchers specify its desired properties and requirements.

Assemble building blocks

Li Zheng, a doctoral student in Kochmann’s group, trained an AI model using a dataset of a million structures and their simulated response. “Imagine a huge box of Lego bricks: you can arrange them in countless ways and, over time, learn design principles. The AI does this extremely efficiently and learns essential design features and how to put them together. basic elements of metamaterials to give them a particular appearance. softness or hardness,” explains Zheng.

Unlike previous approaches using a small catalog of building blocks as a basis for design, the new method gives AI the freedom to add, remove, or move building blocks almost arbitrarily.

Together with Sid Kumar, assistant professor at TU Delft and former member of Kochmann’s team, they showed in a recently published paper that the AI model can even go beyond what it was trained to do and predict structures much better than anything. never generated before.

Learn from cinema

Jan-Hendrik Bastek, also a doctoral student in Kochmann’s group, used a different approach to achieve something similar. It used a method originally introduced for AI-based video generation, and which has become commonplace: if you type in “elephant flying over Zurich,” the AI generates a realistic video of an elephant circling around the church of Fraumünster. Bastek trained its AI system using 50,000 video sequences of 3D printable deforming structures.

“I can insert the trajectory of how I want the structures to deform, and the AI produces a video of the optimal structure and complete deformation response,” Bastek explains. Most previous approaches have focused on single-image prediction of the optimal structure. However, providing the AI with videos of the entire warping process is crucial to maintaining accuracy in such complex scenarios.

Based on the video footage, AI can create plans for new materials, taking into account very complex scenarios.

Big advantages for bicycle helmets and shoe insoles

The researchers have made their AI tools available to the metamaterials community. We hope this will lead to the design of many new and unusual materials. These tools open new avenues for the development of protective equipment such as bicycle helmets and for other applications of metamaterials, from medical engineering to soft robotics.

Even shoe soles can be designed to better absorb shock when running or to provide a forward boost when descending. Will AI completely replace manual engineering design of materials? “No,” Kochmann laughs. “Used well, AI can be a very effective and diligent assistant, but it must be given the right instructions and training, and that requires scientific principles and engineering know-how.”

The work is published in journals Intelligence of natural machines And Natural communications.

More information:

Jan-Hendrik Bastek et al, Inverse design of nonlinear mechanical metamaterials via video denoising diffusion models, Intelligence of natural machines (2023). DOI: 10.1038/s42256-023-00762-x

Li Zheng et al, Unifying the design space and optimizing linear and nonlinear truss metamaterials by generative modeling, Natural communications (2023). DOI: 10.1038/s41467-023-42068-x

Quote: Artificial intelligence for safer bicycle helmets and better shoe soles (December 12, 2023) retrieved December 12, 2023 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.