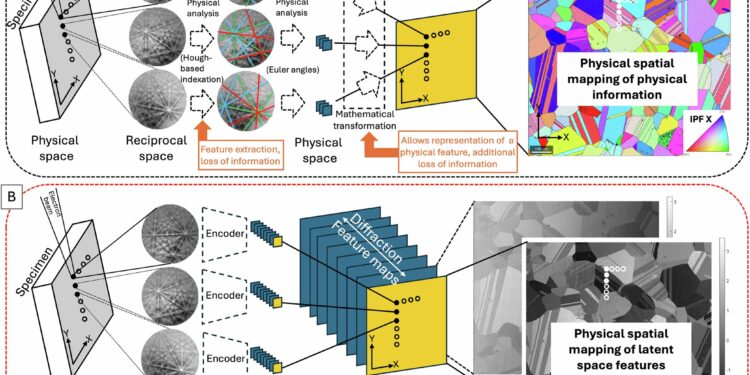

(A) Physics-based approach to extract physical descriptors from reciprocal space and map microstructure heterogeneity by stereographic projection of physical directions (inverse pole figures). (B) Individual Kikuchi models are coded to comprehensively map and highlight microstructural heterogeneity. Credit: Npj computer materials (2025). DOI: 10.1038/s41524-025-01770-8

In a world of 8 billion people, there is one thing that makes each of us unique: our fingerprints. A variety of genetic and environmental factors create tiny variations in the ridges and whorls of the skin, so no two prints are the same.

The spatial distribution of these subtle characteristics makes fingerprints a useful tool for biometric identification. With the help of modern technology, we can even unlock our personal devices using digital maps created from the unique arrangement of ridges, valleys and vascular patterns in our skin. These technologies succeed because of their ability to spatially capture the arrangement of ultra-fine details.

This evolution of recognition technology is reflected in the field of materials science, where researchers are looking for new and efficient ways to fully characterize materials, thereby accelerating the discovery of additional new materials. Much like human fingerprints, the performance of mixtures of metals called alloys relies on the complex spatial arrangement of microstructural features. Traditional methods reduce this complexity into a handful of average values, causing each alloy to lose its distinctive “fingerprint.”

In a recent complement of papers from the lab of Jean-Charles Stinville, assistant professor of materials science and engineering, Illinois Grainger engineers introduced new machine learning approaches to identify the microstructures of alloys and quickly predict their properties. The Illinois researchers’ method will open new avenues for faster and more efficient materials design.

Microstructures are tiny structural features of metals that influence their strength and behavior. Scientists examine the microstructural properties of metals to assess their functionality. Metals used in propulsion devices like rockets and airplanes have special requirements.

“We’re sending these materials into more and more extreme environments,” Stinville said. “They are exposed to intense environments; for example, structural materials intended for space applications must withstand mechanical loads subjected to extremely low or high temperatures.

“Conventional alloys do not perform as well under these conditions because their mechanical properties tend to degrade in these extreme environments. We want to find new ways to accelerate the identification of alloy chemistries and microstructures that can withstand these harsh conditions.”

The complete details of these microstructures, including small-scale influential variances called heterogeneities, cannot be easily captured by existing methods. Instead, Stinville and his colleagues used deep learning to analyze diffraction patterns, or how electrons interact with metals.

By encoding these interactions via a machine learning method on a latent spatial representation, researchers captured the full extent of an alloy’s microstructure and its heterogeneity – an approach Stinville calls Material Spatial Intelligence.

“Traditionally, we use single descriptors or average values to guide data-driven alloy design,” he said. “But spatial information from local measurements over a wide field of view allows us to capture the heterogeneity of the alloy microstructure. Using this spatial information in a data-driven model significantly improves prediction accuracy and enables alloy and microstructure design.”

Published in Npj computer materialsThe initial model is a machine learning approach that successfully identified the microstructures and heterogeneity of materials in unprecedented detail. In a second article published in Scripta MaterialiaStinville advanced the model toward predicting mechanical properties using the developed material spatial intelligence approach. This method accelerates the prediction of alloy properties by several orders of magnitude and enables rapid fundamental understanding of the structural properties of metals.

“I started my career as an experimentalist, where I developed tools that allowed us to collect large fields of view with very high resolution,” he said. “Then I moved to the digital side to develop machine learning tools to actually use all of this spatial information. As a metallurgist, I understand that metals are controlled by their local properties and heterogeneities. My unique background in materials science really helped me develop these new models.”

By combining correlation of high-resolution digital images with characterization of alloy microstructure, Stinville examined tiny regions of metal surfaces and how they deformed on a small scale when loaded. Training a new model to recognize these strain fingerprints allowed it to reliably predict important properties such as strength, lifespan and ductility (the ability to expand without breaking). The model significantly reduces testing time, thereby reducing the time needed to evaluate new alloys. This acceleration brings the field of intelligent alloy design closer.

Stinville envisions a future model that works backwards from the user’s desired properties to suggest a chemical composition and microstructure that best fits the given parameters. By integrating these approaches with his group’s advances in automated characterization, the Stinville lab is paving the way for the design of fully autonomous alloys, marking their next frontier.

But even as exciting advances loom, Stinville remains amazed by the beginnings of his field.

“This approach unites our field’s fundamental understanding of metals with new, efficient AI database tools,” he said. “We don’t just take these new tools and leave behind what we’ve already learned. We integrate the present with the past.”

More information:

Mathieu Calvat et al, Learning the microstructural heterogeneity of metals thanks to the spatial mapping of latent spatial diffraction characteristics, Npj computer materials (2025). DOI: 10.1038/s41524-025-01770-8. www.nature.com/articles/s41524-025-01770-8

Mathieu Calvat et al, Coding and mapping of plasticity during elementary loading for the accelerated prediction of mechanical properties, Scripta Materialia (2026). DOI: 10.1016/j.scriptamat.2025.117082

Provided by the University of Illinois Grainger College of Engineering

Quote: Mapping the future: AI deciphers alloy microstructures to improve property prediction and design (November 18, 2025) retrieved November 18, 2025 from

This document is subject to copyright. Except for fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.