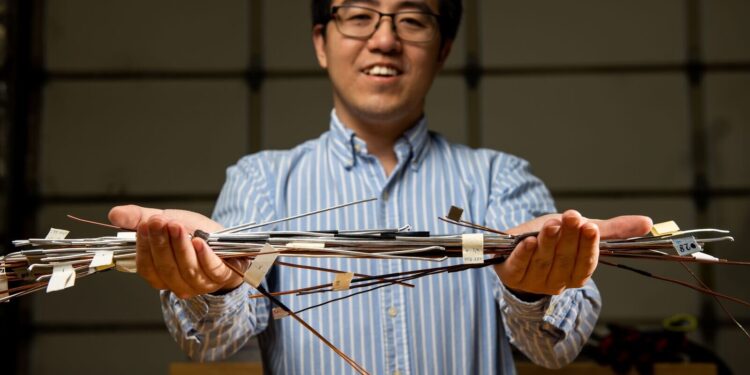

Materials scientist Xiao Li holds samples of highly conductive metal wires created on the patented shear-assisted processing and extrusion platform. Credit: Andrea Starr | Pacific Northwest National Laboratory

A common carbon compound provides remarkable performance improvements when mixed in the right proportion with copper to make electrical wires. It’s a phenomenon that challenges conventional wisdom about how metals conduct electricity.

The results, reported in the journal Materials and design, could lead to more efficient distribution of electricity to homes and businesses, as well as more efficient motors to power electric vehicles and industrial equipment. The team filed a patent application for this work, which was supported by the Department of Energy’s (DOE) Office of Advanced Materials and Manufacturing Technologies.

Materials scientist Keerti Kappagantula and colleagues at DOE’s Pacific Northwest National Laboratory have discovered that graphene, a single layer of the same graphite found in pencils, can improve an important property of metals called coefficient thermal resistance.

This property explains why metal wires heat up when an electric current passes through them. Researchers want to reduce this resistance while improving a metal’s ability to conduct electricity. For several years, people have wondered whether the conductivity of the metal can be increased, particularly at high temperatures, by adding other materials. And if so, can these composites be viable on a commercial scale?

Today, they demonstrated that they can do just that, using an advanced manufacturing platform patented by PNNL called ShAPE.

When the research team added 18 parts per million of graphene to electrical-grade copper, the thermal resistance coefficient decreased by 11% without decreasing electrical conductivity at room temperature. This is relevant to the manufacturing of electric vehicle motors, where an 11% increase in the electrical conductivity of copper wire windings results in a 1% gain in motor efficiency.

“This finding goes against what is generally known about how metals behave as conductors,” Kappagantula said. “Typically, introducing additives to a metal increases its coefficient of temperature resistance, meaning they heat up more quickly at the same current levels as pure metals. We describe a new and exciting property of “this metal composite where we see enhanced conductivity in a manufactured copper wire.”

Microstructure is the key to improving graphene

Previously, the research team carried out detailed physics- and structure-based computational studies to explain the phenomenon of improving the electrical conductivity of metals using graphene.

In this study, they showed that the solid-phase processing used to extrude the composite yarn leads to a uniform, nearly pore-free microstructure punctuated with tiny graphene flakes and clusters that may be responsible for the decrease in the composite’s strength coefficient.

“We showed that flakes and clusters both need to be present to be better conductors for high-temperature operations,” Kappagantula said.

Co-authors Bharat Gwalani, Xiao Li and Aditya Nittala took advantage of a PNNL-designed test bench that measures electrical properties with high precision and accuracy to validate the conductivity improvement, as evidenced by detailed experimental analysis of the team. Li and Md. Reza-E-Rabby developed the tooling and process envelopes for the solid phase friction extrusion process that led to the patent.

Towards more efficient copper motors and wiring for urban buildings

According to the research team, when applied to any industrial application, the new copper-graphene composite wires will provide great design flexibility.

“Wherever there is electricity, we have a use case,” Kappagantula said.

For example, coiled copper wires are used in the cores of electric motors and generators. Today’s motors are designed to operate within a limited temperature range, because when they get too hot, the electrical conductivity drops significantly. With the new copper-graphene composite, motors could potentially operate at higher temperatures without losing conductivity.

Likewise, the wiring that brings electricity from transmission lines to homes and businesses is usually made of copper. As the population density of cities increases, the demand for electricity also follows. A more conductive composite wire could potentially help meet this demand through efficiency savings.

“This technology provides an excellent solution for copper cabling in high-density urban environments,” added Kappagantula.

The research team is continuing its work to customize the copper-graphene material and measure other essential properties, such as strength, fatigue, corrosion and wear, which are crucial to qualifying these materials for industrial applications. For these experiments, the research team makes wires the thickness of a US penny (1.5 millimeters).

More information:

Bharat Gwalani et al, Unprecedented Electrical Performance of Friction Extruded Copper-Graphene Composites, Materials and design (2023). DOI: 10.1016/j.matdes.2023.112555

Provided by Pacific Northwest National Laboratory

Quote: Adding a small amount of solid carbon to copper increases its conductivity (December 20, 2023) retrieved December 20, 2023 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.