Credit: Ryu et al. (Natural energy2023).

Over the past decades, engineers and materials scientists have worked hard to develop battery technologies with increasingly higher performance. Their efforts aim to meet the needs of the electronics industry, increasing the battery life of countless rechargeable devices, electric vehicles and robotic systems.

Nickel (Ni)-rich layered materials have often been used as cathodes in battery cells, due to their advantageous properties that can increase the energy density of the cells. However, the capacity of Ni-rich cathodes can quickly deteriorate, due to material reactivity that causes unwanted secondary chemical reactions.

Researchers at Hanyang University in Seoul recently introduced a new strategy that could help improve the performance of these cathodes, allowing them to retain their capacity for longer periods of time. This strategy, presented in an article published in Natural energyinvolves a simple washing process that removes residual lithium compounds on the cathodes, while coating them to reduce unwarranted reactions.

“The instability of Ni-rich layered cathode materials in lithium-ion batteries is attributed to their labile surface reactivity,” Hoon-Hee Ryu, Hyung-Woo Lim and colleagues wrote in their paper. “This reactivity induces the formation of residual lithium impurities on the cathode surface and severe side reactions with the electrolyte. We propose a washing process using co-dissolved water to simultaneously remove residual lithium and form a protective coating on Ni-rich layered cathodes.”

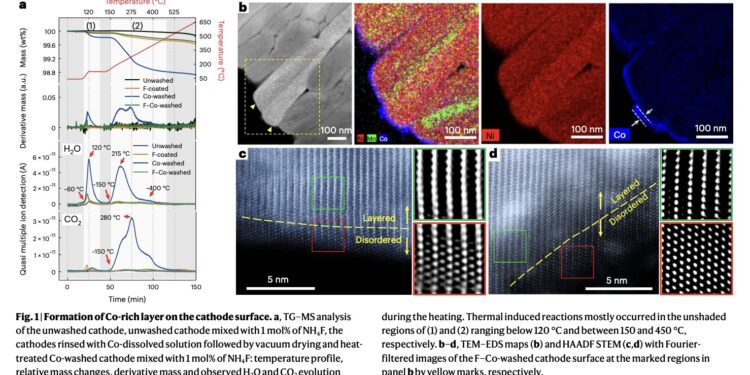

The main goal of this team of researchers’ recent work was to identify an effective method to overcome the limitations of Ni-rich cathodes, which could in turn help increase battery life over time. The proposed strategy involves washing the cathodes with a dissolved aqueous cobalt (Co) solution.

This washing process causes a reaction with residual lithium on the external surface of the cathodes, leading to the formation of a thin, uniform, Co-rich protective layer. The layer formed eliminates direct contact between the cathode and the electrolyte at inside the battery cell, thereby preventing further side reactions and the resulting rapid degradation of the cathode over time.

“Washing induces reconstruction of the near-surface structure through reactions with residual lithium compounds, thereby preventing direct contact between the electrolyte and the Ni-rich surface,” explained Ryu, Lim and their colleagues. “An additional fluorine coating on the washed cathode prevents salt decomposition, preventing byproducts from triggering autocatalytic side reactions at the electrolyte-cathode interface and thus suppressing gas generation during cycling.”

The washing and coating strategy introduced by Ryu, Lim, and co-workers was tested in a series of initial experiments. The results showed that it successfully extended the life cycle of Ni-rich cathodes, without compromising their energy density and safety.

In the future, this recent work could be used to develop safer and more durable batteries for electric vehicles and other electronic devices on a large scale. Furthermore, other research teams could draw inspiration from its results to design other promising methods to prevent the rapid capacitance deterioration commonly reported in Ni-rich cathodes.

More information:

Hoon-Hee Ryu et al, Near-surface reconstruction in Ni-rich layered cathodes for high-performance lithium-ion batteries, Natural energy (2023). DOI: 10.1038/s41560-023-01403-8.

© 2023 Science X Network

Quote: A strategy to reduce the rapid deterioration of the capacity of Ni-rich cathodes (December 22, 2023) retrieved December 22, 2023 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.