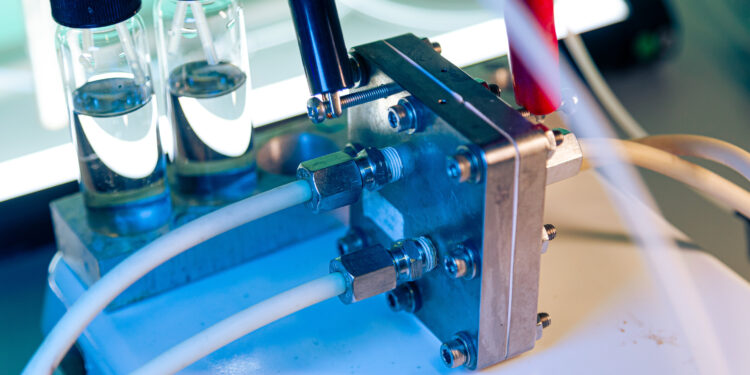

IIT and BeDimensional researchers used nanoparticles of ruthenium, a noble metal similar to platinum in its chemical behavior but much cheaper, to serve as the active phase of the electrolyzer cathode, thus leading to increased efficiency of the overall electrolyzer. Credit: IIT-Istituto Italiano di Tecnologia

What is needed to produce green hydrogen more efficiently and at lower cost? Apparently, small particles of ruthenium and a solar-powered water electrolysis system. This is the solution proposed by a joint team involving the Istituto Italiano di Tecnologia (Italian Institute of Technology, IIT) in Genoa and BeDimensional SpA (an IIT spin-off).

The technology, developed as part of the Joint-lab activities and recently published in Natural communications and the Journal of the American Chemical Societyis based on a new family of electrocatalysts that could reduce the costs of producing green hydrogen on an industrial scale.

Hydrogen is considered a sustainable energy vector, an alternative to fossil fuels. But not all hydrogens are the same in terms of environmental impact. Indeed, the main way to produce hydrogen today is through steam methane reforming, a fossil fuel-based process that releases carbon dioxide (CO).2) as a by-product. The hydrogen produced by this process is classified as “gray” (when the CO2 is released into the atmosphere) or “blue” (when CO2 undergoes capture and geological storage).

To significantly reduce emissions to zero by 2050, these processes must be replaced with more environmentally sustainable processes that deliver “green” (i.e. net zero emissions) hydrogen. The cost of “green” hydrogen essentially depends on the energy efficiency of the installation (the electrolyzer) which divides the water molecules into hydrogen and oxygen.

The researchers of the joint team of this discovery have developed a new method which guarantees greater efficiency than currently known methods in the conversion of electrical energy (the energy bias exploited to split water molecules) into chemical energy stored in the hydrogen molecules produced. . The team developed a catalyst concept and used renewable energy sources, such as electrical energy produced by a solar panel.

“In our study, we have shown how it is possible to maximize the efficiency of a robust and well-developed technology despite a slightly higher initial investment than would be necessary for a standard electrolyser. metal such as ruthenium,” said Yong Zuo and Michele Ferri from the nanochemistry group at IIT Genoa.

The researchers used nanoparticles of ruthenium, a noble metal whose chemical behavior is similar to platinum but much cheaper. Ruthenium nanoparticles serve as the active phase of the electrolyzer cathode, leading to increased efficiency of the overall electrolyzer

“We carried out electrochemical analyzes and tests under significant industrial conditions which allowed us to evaluate the catalytic activity of our materials. In addition, theoretical simulations allowed us to understand the catalytic behavior of ruthenium nanoparticles at the level molecular; in other words, the mechanism of water dividing on their surface,” explained Sebastiano Bellani and Marilena Zappia of BeDimensional, who participated in the discovery.

“By combining data from our experiments with additional process parameters, we performed a techno-economic analysis that demonstrated the competitiveness of this technology compared to state-of-the-art electrolyzers.”

Ruthenium is a precious metal obtained in small quantities as a by-product of platinum extraction (30 tonnes per year, compared to 200 tonnes of platinum per year) but at a lower cost (18.5 dollars per gram compared to 200 tonnes per year ). 30 dollars for platinum). The new technology involves the use of only 40 mg of ruthenium per kilowatt, which contrasts sharply with the extensive use of platinum (up to 1 gram per kilowatt) and iridium (between 1 and 2.5 grams per kilowatt, the price of iridium being around 150 dollars). per gram) which characterize proton exchange membrane electrolyzers.

Using ruthenium, IIT and BeDimensional researchers have improved the efficiency of alkaline electrolyzers, a technology that has been used for decades due to its robustness and durability.

For example, this technology was aboard the Apollo 11 capsule that brought humanity to the Moon in 1969. The new family of ruthenium-based cathodes for alkaline electrolyzers that has been developed are highly efficient and have a long lifespan. life, therefore being able to reduce the production costs of green hydrogen.

“In the future, we plan to apply this and other technologies, such as nanostructured catalysts based on sustainable two-dimensional materials, in large-scale electrolyzers powered by electrical energy from renewable sources, including electricity produced by photovoltaic panels,” the researchers concluded. .

More information:

Yong Zuo et al, Ru–Cu Nanoheterostructures for Efficient Hydrogen Evolution Reaction in Alkaline Water Electrolyzers, Journal of the American Chemical Society (2023). DOI: 10.1021/jacs.3c06726

Yong Zuo et al, High-performance alkaline water electrolyzers based on Ru-disrupted Cu nanoplatelet cathode, Natural communications (2023). DOI: 10.1038/s41467-023-40319-5

Provided by the Italian Institute of Technology

Quote: A new system to produce green hydrogen cheaply and efficiently (December 13, 2023) retrieved December 14, 2023 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.