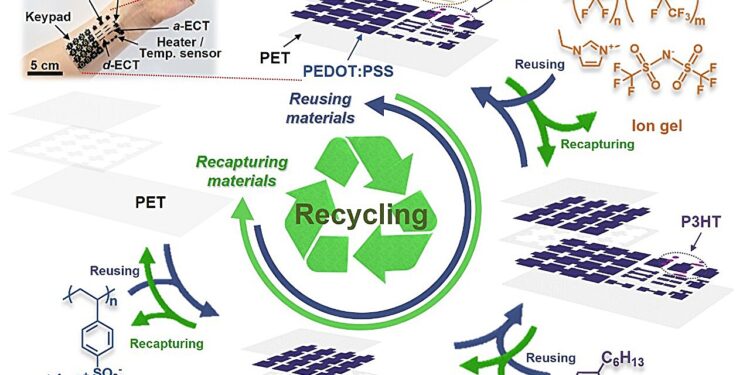

Schematic illustration of ROF (Recyclable Organic Flexible) electronics. Credit: Park et al.

The electronics industry has seen continuous development over the past decades, leading to the development, manufacturing and sale of a wide range of consumer devices. In recent years, many engineers have focused their efforts on flexible electronics that can be used to create wearable devices, such as smart watches, headphones, fitness trackers and even smart jewelry, as well as electronic implants for medical applications.

Although significant progress has been made in the development of flexible electronics, the widespread commercialization of an increasing number of electronic devices has raised significant concerns about their durability. Certain research teams have thus attempted to identify environmentally friendly materials and manufacturing strategies likely to mitigate the negative impact of the electronics industry on the planet.

Researchers at the Ulsan National Institute of Science and Technology (UNIST) in South Korea recently introduced a new method for creating organic, flexible electronic devices with recyclable components. This method, described in an article in Natural electronicsrelies on reusable materials and environmentally friendly solvents that have minimal impact on the environment.

“This paper is the culmination of extensive research in the field of wearable organic electronics,” Kyoseung Sim, co-author of the paper, told Tech Xplore. “Recognizing the environmental concerns associated with the disposal and synthesis of organic electronic materials, our study was motivated by the need for sustainable solutions in this rapidly evolving field.”

Organic materials, carbon-based compounds found in nature or from artificial terrestrial and aquatic environments, can have significant advantages over inorganic (i.e., non-carbon-containing) materials when is about electronics development. Although these materials are often more cost-effective and naturally flexible than inorganic compounds, their environmental impact has become a subject of debate.

“Our paper addresses concerns about the sustainability of electronic products based on organic materials by introducing innovative recycling technologies,” explained Sim. “Unlike existing methods primarily focused on inorganic components, our research aims to innovate comprehensive recycling processes for organic semiconductors and conductors, paving the way for the sustainable development of wearable electronics.”

Schematic illustration of the durable device cycle of ROF electronics. Credit: Park et al.

In their paper, Sim and colleagues present a new approach to creating so-called recyclable organic flexible (ROF) electronic components designed for closed-loop recyclability. This approach eliminates the need to introduce additional non-recyclable components into new electronic devices, thereby reducing material waste.

“Our method relies on the selective dissolution of organic components, allowing for efficient recovery and reuse,” Sim said. “This innovative process not only facilitates the complete recycling of organic wearable electronic components, but also presents a revolutionary method that could revolutionize the industry’s approach to sustainability in future wearable technologies.”

In their paper, the researchers demonstrate how the proposed method could be applied to the development of various electronic devices, including electrophysiological sensors, keyboards, heat/temperature sensors, transistors, and inverters.

Their initial findings highlight the potential value of their approach to reducing e-waste by reusing components based on organic materials, while eliminating non-recyclable components and chemicals known to harm the environment.

“The process we developed enables the selective dissolution and recovery of organic components with minimal material loss, thereby establishing a closed-loop recycling system for ROF electronics,” Sim said.

“This advancement has profound implications for e-waste management, potentially contributing to the reduction of e-waste and the promotion of sustainability in the electronics industry. Additionally, the scalability and cost-effectiveness of our recycling technology presents significant economic benefits and opportunities for sustainable innovation. electronic manufacturing.”

In the future, the cycle of sustainable devices described in this recent article could serve as inspiration for electronics manufacturers looking to reduce waste and introduce new eco-friendly practices. Additionally, the researchers hope their work will encourage others in the field to focus their efforts on increasing the durability of electronic devices.

“Our future research efforts will aim to expand the scope of recyclable organic electronics, focusing on more complex and diverse applications,” Sim added.

“We plan to refine and improve the efficiency and environmental friendliness of manufacturing and recycling processes. Another critical area of our future work involves the development of new organic electronic materials. Advancing this area , we hope to encourage collaborative research efforts towards sustainable wearable technologies.

More information:

Haechan Park et al, Organic flexible electronics with closed-loop recycling for sustainable wearable technology, Natural electronics (2023). DOI: 10.1038/s41928-023-01078-9.

© 2024 Science X Network

Quote: A new method for developing recyclable, organic and flexible electronics (January 10, 2024) retrieved on January 10, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.