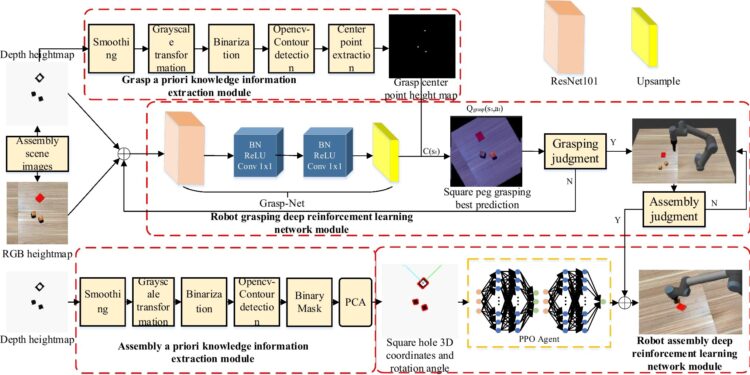

The scheme of deep reinforcement learning method for robot grasping and assembly operation skills. Credit: The International Journal of Advanced Manufacturing Technologies (2024). DOI: 10.1007/s00170-024-13004-0

Semi-autonomous and autonomous robots are being introduced into a growing number of real-world environments, including industrial ones. Industrial robots could speed up the manufacturing of various products by helping human workers with basic tasks and easing their workload.

Two of the most crucial tasks in manufacturing are object picking and product assembly, but completing these tasks reliably using robotic systems can be difficult. One of the main limitations of industrial robots for automated assembly lines is that they must be broadly programmed to perform specific tasks (e.g., grasp and assemble specific items), and their product-specific programming can take time. time.

Researchers at Qingdao University of Technology recently decided to tackle this crucial limitation of industrial robots using deep reinforcement learning. Their article, published in The International Journal of Advanced Manufacturing Technologiesintroduced new deep learning algorithms that could speed up the time it takes to train industrial robots on new gripping and assembly tasks.

“This paper proposes a deep reinforcement learning-based framework for autonomous learning of robot grasping and assembly skills,” Chengjun Chen, Hao Zhang and colleagues wrote in their paper.

“At the same time, a robot grasping skill learning algorithm based on deep Q-learning and a robot assembly skill learning algorithm based on PPO are presented, in which a priori knowledge information is introduced to optimize the gripping action and reduce the training time and interaction data needed by the assembly strategy learning algorithm.

The new robot training techniques presented in this recent article leverage computer vision and machine learning tools introduced in recent years. First, the researchers developed a deep learning algorithm designed to quickly teach robots new object-grasping skills, as well as a separate algorithm to train robots to assemble specific objects.

At the same time, they also designed reward functions that can be used to effectively assess the grasping and assembly skills of industrial robotic systems. These include both grasping and assembly constraint reward functions.

To assess the potential of their proposed robotics training toolkit, Chen, Zhang and their colleagues tested it both in simulations and on physical industrial robots. In their real-world experiments, the team specifically used the UR5, a lightweight robotic arm often applied to industrial tasks, along with a RealSense D435i camera to collect RGB images of objects, which their algorithms could then analyze.

“The effectiveness of the proposed framework and algorithms was verified in simulated and real environments, and the average grasping success rate in both environments reached 90%. Under a dowel assembly tolerance of 3 mm, the assembly success rate was 86.7% and 73.3% in the simulated environment and the physical environment, respectively,” the researchers wrote in their article.

The initial results collected by Chen, Zhang and their collaborators are very promising, suggesting that their toolbox of training algorithms could accelerate the programming of industrial robots, quickly teaching them to reliably grasp and assemble objects. In their next studies, the researchers plan to further improve their approach and continue testing it on common grasping and assembly tasks.

“In future work, we will improve the hole detection accuracy and hole shape and image domain randomization in the virtual environment, optimize the strategy from the simulation environment to the physical environment and “We will reduce errors in both stages to improve the assembly success rate in the physical environment,” the researchers concluded.

More information:

Chengjun Chen et al, Autonomous learning of robot grasping and assembly skills based on deep reinforcement learning, The International Journal of Advanced Manufacturing Technologies (2024). DOI: 10.1007/s00170-024-13004-0

© 2024 Science X Network

Quote: A Deep Reinforcement Learning Approach to Improve Autonomous Robotic Grasping and Assembly (February 6, 2024) retrieved February 6, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.