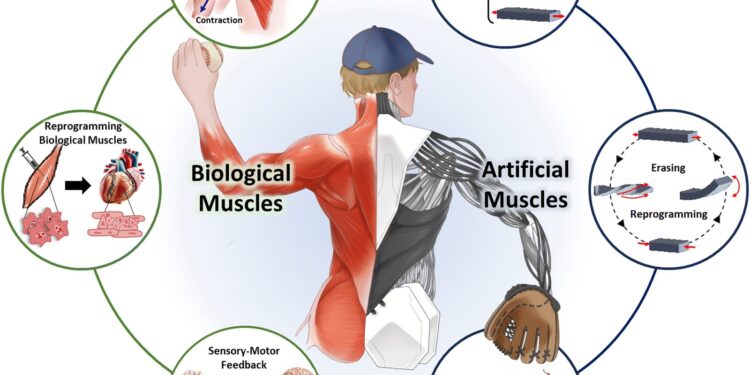

Comparison between biological muscles and intelligent artificial muscles, highlighting multi-mode dynamics, reprogrammability and integrated sensory feedback. Credit: Horizons Materials (2025). DOI: 10.1039/d5mh00236b

Pop culture has often portrayed robots as cold, metallic, and menacing, built for dominance, not compassion. But at Georgia Tech, the future of robotics is gentler, smarter and designed to help.

“When people think of robots, they usually imagine something like The Terminator or RoboCop: big, rigid and made of metal,” said Hong Yeo, a “Bud” Peterson GP and Valerie H. Peterson Professor at the George W. Woodruff School of Mechanical Engineering. “But what we are developing is the opposite. These artificial muscles are soft, flexible and responsive, more like human tissue than machines.”

Yeo’s latest study, published in Horizons Materialsexplores AI-powered muscles made from realistic materials combined with intelligent control systems. The technology learns from the body and adapts in real time, creating movement that is natural, responsive and safe enough to promote recovery.

Muscles that think, materials that feel

Traditional robotics relies on steel, wires and motors, but rarely captures the nuances of human movement. Yeo’s research takes a different approach. It uses hierarchically structured fibers, which are flexible materials built in layers, much like muscles and tendons. They can sense, adapt, and even “remember” how they moved before.

Yeo trains machine learning algorithms to adjust these soft materials in real time with the right amount of force or flexibility for each task.

“These muscles don’t just respond to commands,” Yeo said. “They learn from experience. They can adapt and self-correct, which makes movements smoother and more natural.”

The result of this research is profoundly human. For someone recovering from a stroke or limb loss, each deliberate movement not only rebuilds strength, it restores confidence, independence and self-esteem.

A glove that gives back freedom

One of the first real-world applications is a prosthetic glove powered by artificial muscles (published in ACS Nano), a device that behaves more like a helping hand than a mechanical tool. Traditional prosthetics rely on rigid motors and predefined movements, but Yeo’s design reflects the natural exchanges of real muscles.

Inside the glove, thin layers of stretch fibers and sensors contract, twist, and bend in sync with the wearer’s intent. The glove can refine grip strength, reduce tremor and respond instantly to the user’s movements, bringing back daily dexterity.

This type of precision is particularly important in the smallest tasks: closing a button, lifting a glass, holding a child’s hand.

“It’s not just movements,” Yeo said. “These are freedoms.”

For Yeo, the idea of restoring freedom through movement guided his research from the beginning.

A mission rooted in loss

Yeo’s work is deeply personal. His journey to biomedical engineering began with a loss: the sudden death of his father while Yeo was still in college. This moment reshaped his sense of purpose, reorienting his focus from machines that move to technologies that heal.

“I originally thought about designing cars,” he said. “But after my father died, I kind of woke up. Maybe I could do something that would help save someone’s life.”

This goal continues to guide his lab’s work today, creating technologies that help people regain what they’ve lost.

However, achieving this vision requires overcoming some of engineering’s toughest challenges.

Soft machines, hard problems

Creating realistic muscles is not easy. They should be soft but strong, responsive but safe. And they must avoid triggering the body’s immune system. This means building materials that can survive inside the body and learn to belong there.

“We always think about not only function, but also adaptability,” Yeo said. “If it’s going to be part of someone’s body, it has to work with them, not against them.”

His team calibrates these synthetic fibers like precision instruments: tested, adjusted and readjusted until they work in sync with the body’s natural movements. Over time, they develop a kind of “muscle memory,” adapting fluidly to changing conditions. This dynamic adaptability, Yeo explained, is what differentiates a machine from a prosthetic that truly feels alive.

From collaboration to innovation

Solving such complex problems requires more than one discipline. This requires an entire ecosystem of collaboration. Yeo’s lab brings together experts in mechanical engineering, materials science, medicine and computer science to design smarter and safer devices.

“You can’t solve this kind of problem in isolation,” he said. “We need all of this – polymers, artificial intelligence, biomechanics – to work together.”

His team is now working closely with healthcare providers and industry partners to get these devices out of the lab and into patients’ lives.

The future you can feel

According to Yeo, the future of robotics will not be defined by power or complexity but by sensation.

“If it looks foreign, people won’t use it,” he said. “But if it’s a part of you, that’s when it can really change lives.”

It’s the opposite of The Terminator, where machines replace us. Yeo designs these machines to help us reclaim ourselves.

More information:

Saewoong Oh et al, Enhancing the Intelligence of Artificial Muscles: Recent Advances in Materials, Design and Manufacturing, Horizons Materials (2025). DOI: 10.1039/d5mh00236b

Tae Woog Kang et al, Wearable multimodal sensing and feedback system activated by a soft nanomembrane sensor for assistance with upper limb sensory impairments, ACS Nano (2025). DOI: 10.1021/acsnano.4c15530

Provided by Georgia Institute of Technology

Quote: Human-centered soft robotics flips the script of “The Terminator” (October 30, 2025) retrieved October 30, 2025 from

This document is subject to copyright. Except for fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.