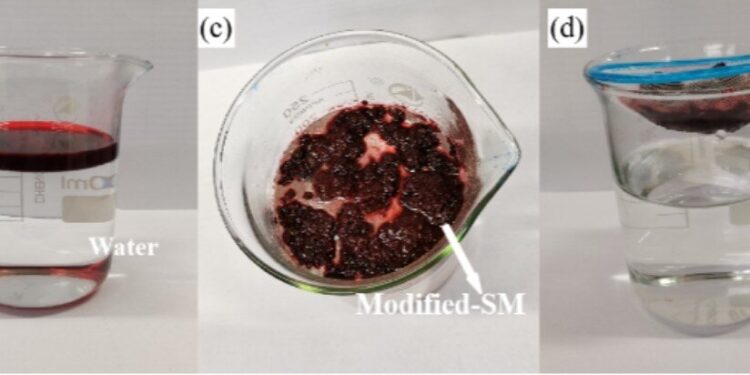

Adsorption of oil pollution by the modified sphagnum foam (Modified SM): (a) Macroscopic morphology of modified sphagnum foam, (b) Mixture of oil-water adsorption, (c) Adsorption process showing a adsorbed material, and (D, e) separation of the material after adsorption. Credit: Scientific relationships (2025). DOI: 10.1038 / S41598-025-96059-7

Hidden in sphagnum foam, commonly known as peat foam, is an adsorbent material that can help us fight against oil spills. A study carried out by Chinese researchers has a new adsorbent of biosormed oil derived from sphagnum foam which can soak up the oil.

The chemical modification of the peat peat has led to a potential oil sponge with the ability to maintain more than 90% of the initial adsorption capacity even after 10 cycles of use, according to the results published in Scientific relationships.

Each year, hundreds of tons of oil overturned in water bodies due to the fact that oil drilling has gone wrong, pipeline leaks and large flowing oil transport ships. These spills of oil and chemicals can have devastating effects on aquatic fauna, poisoning of habitats and the disturbance of the food chain, among other serious consequences. Humans are not safe from the impact of these oil spills, as exposure can affect the lungs, the heart and the immune system.

The growing urgency to cope with deadly oil spills has prompted scientists to explore bio-base materials that can effectively separate oil from water. However, current bio-base adsorbents derived from fruit or cotton peels often suffer from low capacity, bad reusability and their inherent hydrophilic nature makes the selective adsorption of oil from rather difficult oil-water mixtures.

To design a natural material that could overcome these problems, scientists have chosen sphagnum foam as a basic material, then treated it with hydrogen peroxide and sodium hydroxide, sequentially.

Hydrophobic and olive properties of the original sphagnum foam (AC) and modified sphagnum foam (DF). Credit: Scientific relationships (2025). DOI: 10.1038 / S41598-025-96059-7

These chemicals increased the porosity of the surface of the foam and exhibits the hydrophilic functional groups which make the surface of the foam that loved water. The material obtained was then treated with Silane, a surface modifier based on popular silicon, which formed a thin polymer layer on the surface of the foam, which makes it more attracted by oil by introducing oléophilic groups and covering the hydrophilic groups.

A more in -depth examination of the modified MOSS using the scanning electron microscopy and spectroscopic techniques has revealed a rough surface, successfully grafted with groups distributed in water, creating a 157 ° contact angle for water to take place easily.

This led to increased selectivity towards oil, which was obvious from the adsorption tests, where the modified sphagnum foam had an adsorption capacity of 22,756 g / g for engine oil, outperforming many popular bio-base adsorbents, whose capacities vary from 1.69 to 18.2 g / g.

Mechanistic diagram of the separation of separation of oily waters. Credit: Scientific relationships (2025). DOI: 10.1038 / S41598-025-96059-7

Researchers have also discovered that chemisorption – the process of adsorption for adsorption of strong chemical bonds between oil molecules and the functionalized surface – was the dominant mechanism which has contributed to an increased adsorption effectiveness and the affinity of the oil.

The adsorbent of modified foam oil is presented as a promising and environmentally friendly tool to combat oil spills, thanks to its excellent adsorption performance and reusability.

More information:

Junpeng Ren et al, bio-base adsorbent with a durable hydrophobic based from modified sphangigne foam for an effective separation of oil, Scientific relationships (2025). DOI: 10.1038 / S41598-025-96059-7

© 2025 Science X Network

Quote: Adsorbent based on reusable foam can help clean oil spills (2025, April 18) recovered on April 19, 2025

This document is subject to copyright. In addition to any fair program for private or research purposes, no part can be reproduced without written authorization. The content is provided only for information purposes.