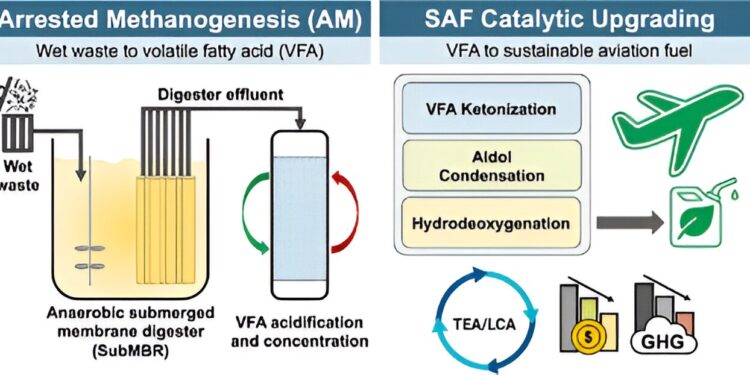

Graphical summary. Credit: ACS Sustainable Chemistry and Engineering (2024). DOI: 10.1021/acssuschemeng.4c00167

Made from renewable materials like biomass and agricultural waste, sustainable aviation fuel has enormous potential to decarbonize the aviation industry. But widespread adoption has yet to take off.

Sustainable aviation fuel (SAF) represents less than 1% of the fuel used in the aviation industry, while aviation fuel contributes to approximately 3% of global greenhouse gas (GHG) emissions. Producing SAFs that are more energy efficient, cheaper, and more competitive than fossil fuel-based jet fuel is essential for widespread commercial use.

Now, scientists at Argonne National Laboratory have developed new technology that creates a competitive SAF that could reduce GHG emissions in the aviation industry by up to 70 percent. Argonne’s life cycle and techno-economic models were used to analyze the environmental impacts and economic viability of the SAF.

Research in ACS Sustainable Chemistry and Engineering shows that novel methane-arrested anaerobic digestion (MAAD) technology converts high-strength organic wastewater into volatile fatty acids, which can be upgraded to SAF.

As key precursors in SAF production, volatile fatty acids can play a critical role in decarbonizing the aviation industry, said Haoran Wu, a postdoctoral researcher at Argonne.

“Volatile fatty acids from waste streams can make biofuel production more profitable and sustainable,” Wu said. “Argonne’s new technology uses a membrane-assisted bioreactor to improve the production of volatile fatty acids. “

The research advances goals outlined in DOE’s Sustainable Aviation Fuel Grand Challenge, which aims to increase SAF production to three billion gallons by 2030. The goal is to produce enough fuel to meet 100 percent of demand for commercial jet fuel by 2050.

Conversion of waste streams into biofuel

Biofuels are in demand to decarbonize hard-to-electrify sectors like aviation. Conversion of biomass to biofuel is a complex process involving variables in the organic materials used as feedstock, as well as conversion, separation and purification technologies to meet fuel specifications.

Instead of relying on more conventional resources like fat, oil and grease, the scientists used carbon-rich wastewater from breweries and dairy farms as a raw material for their innovative technology. In a major breakthrough, the technology removes organic carbon from these high-strength waste streams that would otherwise be difficult to treat profitably.

“Both wastewater streams are rich in organic matter, and their treatment using traditional wastewater treatment methods requires a lot of carbon,” said study author Taemin Kim, a systems analyst. Argonne energy companies. “Using our technology, we not only treat these waste streams, but we also produce a sustainable, low-carbon fuel for the aviation industry.”

Argonne’s technology also innovates in converting these waste streams into SAF.

Anaerobic digestion is an established technology for converting biomass into methane and then biofuel. Developed by Meltem Urgun Demirtas, head of the Sustainable Materials and Processes department at Argonne, MAAD technology focuses instead on the production of volatile fatty acids (such as butyric acid) and lactic acid.

However, lactic acids limit the production of SAF from volatile fatty acids. Argonne MAAD technology overcomes this limitation to increase the yield of volatile fatty acids.

“Lactic acid reduces the efficiency of carbon when converting volatile fatty acids into SAF,” Wu said. “Therefore, it is essential to shift the conversion from lactic acid to the production of fatty acids. volatile.”

In another groundbreaking innovation, scientists developed an electrochemical separation method to improve membrane-assisted MAAD technology.

“We developed an in situ product recovery process to increase retention time in membrane-assisted digesters, which enabled resilient microbial communities with abundant butyric acid producers and increased productivity and the concentration of the acid, thereby reducing the cost of producing the acid and the toxicity of the acid,” Urgun said. Demirtas, principal investigator of the research.

Analyze economic and environmental impacts

Using experimental data, scientists used Argonne’s advanced simulation and modeling tools to design three possible waste pathways to SAF and compared them to conventional jet fuel produced from fossil fuels.

Using the process models, the scientists carried out a techno-economic and life cycle analysis of the sectors. The life cycle analysis was performed using Argonne’s R&D Greenhouse Gases, Regulated Emissions, and Energy Use in Technologies (R&D GREET) model to assess the GHG impacts from production to final use.

Scientists say the waste-to-aviation fuel pipeline significantly reduces carbon emissions compared to conventional jet fuel. The study also expands the use of lesser-used waste at a time when demand for typical biological feedstocks for SAF is leading to a shortage.

Although research continues, scientists hope to eventually commercialize the patent-pending process and expand the technology for widespread use.

“Designing a membrane-assisted technology that achieves a 70% reduction in greenhouse gases at a cost comparable to conventional jet fuel is a significant advance,” Wu said.

“We will continue to work to improve sustainability and begin to explore other raw materials to use with our technology.”

Pahola Thathiana Benavides Gallego, Argonne’s senior energy systems analyst, also served as principal investigator on the research.

More information:

Haoran Wu et al, Sustainable aviation fuel from high-strength wastewater via membrane-assisted volatile fatty acid production: experimental evaluation, techno-economic and life cycle analyses, ACS Sustainable Chemistry and Engineering (2024). DOI: 10.1021/acssuschemeng.4c00167

Provided by Argonne National Laboratory

Quote: New technology converts wastewater into sustainable aviation fuel with potential 70% reduction in emissions (October 10, 2024) retrieved October 10, 2024 from

This document is subject to copyright. Except for fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for informational purposes only.