Thermodynamic analysis and implementation of the ETC/ETCC process. Credit: Nature Chemical Engineering (2024). DOI: 10.1038/s44286-024-00125-2

A research team led by James Tour of Rice University has developed a method to more efficiently recycle precious metals from electronic waste while significantly reducing the environmental impact typically associated with metal recycling.

Recycling metals can reduce the need for mining, which reduces environmental damage associated with raw material extraction such as deforestation, water pollution and greenhouse gas emissions.

“Our process significantly reduces operating costs and greenhouse gas emissions, making it a breakthrough in sustainable recycling,” said Tour, the TT and WF Chao Professor of Chemistry and professor of materials science and nanoengineering.

The research team’s work was published in Nature Chemical Engineering September 25th.

Innovative technique

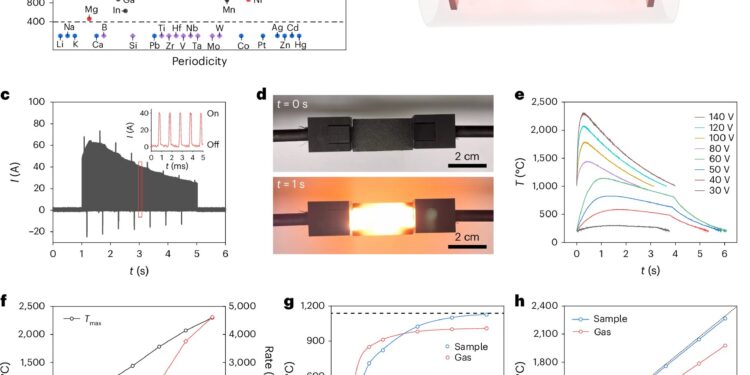

This new technique improves the recovery of critical metals and builds on Tour’s previous work on waste disposal using flash Joule heating (FJH). This process involves passing an electric current through a material to rapidly heat it to extremely high temperatures, transforming it into different substances.

The researchers applied the FJH chlorination and carbochlorination processes to extract valuable metals, including gallium, indium, and tantalum, from e-waste. Traditional recycling methods such as hydrometallurgy and pyrometallurgy are energy-intensive, produce harmful waste streams, and involve large amounts of acid.

In contrast, the new method eliminates these challenges by enabling precise temperature control and rapid separation of metals without the use of water, acids or other solvents, thereby significantly reducing environmental damage.

“We are trying to adapt this method to recover other critical metals from waste streams,” said Bing Deng, a former Rice postdoctoral student, now an assistant professor at Tsinghua University and co-first author of the study.

Effective results

The scientists found that their method could efficiently separate tantalum from capacitors, gallium from discarded light-emitting diodes, and indium from used solar conductive films. By precisely controlling the reaction conditions, the team achieved a metal purity of more than 95% and a yield of more than 85%.

Additionally, the method holds promise for extracting lithium and rare earths, said Shichen Xu, a postdoctoral researcher at Rice and co-first author of the study.

“This breakthrough addresses the urgent issue of critical metal shortages and negative environmental impacts while economically encouraging recycling industries globally with a more efficient recovery process,” Xu said.

Other authors of the study include Jaeho Shin, Yi Cheng, Carter Kittrell, Justin Sharp, Long Qian, Shihui Chen and Lucas Eddy of Rice’s Department of Chemistry and Khalil JeBailey of Rice’s Department of Materials Science and Nanoengineering.

More information:

Bing Deng et al, Flash separation of metals by electrothermal chlorination, Nature Chemical Engineering (2024). DOI: 10.1038/s44286-024-00125-2. www.nature.com/articles/s44286-024-00125-2

Provided by Rice University

Quote:Sustainable method of recycling metals reduces costs and greenhouse gas emissions (2024, September 25) retrieved September 25, 2024 from

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without written permission. The content is provided for informational purposes only.