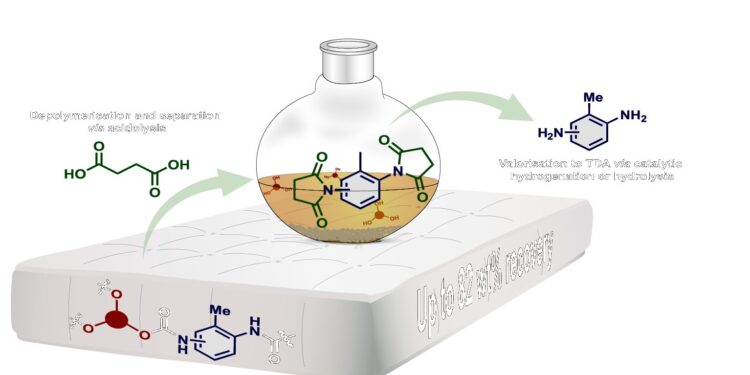

The graph shows how the new combination of acidolysis and hydrolysis can recover up to 82% by weight of the original material of the soft PUR foam used in mattresses, in the form of two separate fractions of diamines and polyols. The diamine is indicated as TDA (toluene diamine). Credit: Thomas Balle Bech, Aarhus University

Researchers at Aarhus University have discovered a better way to recycle polyurethane foam from items such as mattresses. This is great news for the fledgling industry that aims to chemically recover the original components of the material, making its products cheaper and better.

Polyurethane (PUR) is an indispensable plastic material used in mattresses, refrigerator and building insulation, shoes, cars, airplanes, wind turbine blades, cables and much more. It could be called a miracle material if it were not also an environmental and climate burden. Most of the PUR products discarded worldwide end up being incinerated or dumped in landfills.

This is problematic because the main components of the material are mainly extracted from fossil oil. And we are talking about significant quantities. In 2022, the global PUR market reached almost 26 million tons, and forecasts for 2030 predict almost 31.3 million tons, of which about 60% will be foam in various forms.

There is, however, a small but growing industry that chemically breaks down (depolymerizes) PUR into its original main components, polyol and isocyanate, with the aim of reusing them as raw materials in new PUR products.

There is still much to be done before their production can truly compete with that of “virgin” materials. Separation and purification of the desired elements are costly.

Break down and separate in one go

This is where a team of researchers from Aarhus University comes in, who have come up with a brilliant idea. They based their work on a method already used by the companies in question, namely the decomposition of PUR foam by acid (acidolysis).

But companies do not separate the PUR that has been broken down into polyol and isocyanate. The result is a mixture that cannot be recycled directly, but forces their customers to use new recipes.

The AU researchers are not only able to break down PUR and separate the two main components, they do it in one go. They heat flexible PUR foam to 220 °C in a reactor with a little succinic acid (see box). They then use a filter that retains one material and lets the other through.

These are the polyols that pass through and they do so in a quality comparable to that of virgin polyol, which allows them to be used in the new polyurethane production. The filtered solid part of the product mixture is converted into a diamine in a simple hydrolysis process, which is used in the production of isocyanates and thus PUR.

The researchers were thus able to recover up to 82% of the weight of the original material of the soft PUR foam used in mattresses, in the form of two distinct fractions of diamines and polyols. The researchers recently published their results in the journal Green chemistry.

Huge potential in the industry

“The method is easy to implement on a large scale,” says one of the study’s authors, Steffan Kvist Kristensen, assistant professor at the Interdisciplinary Centre for Nanoscience (iNANO) at Aarhus University.

He sees enormous potential for recycling PUR foam waste in factories that use it as raw material (plates) in their production.

“But the prospect of also processing PUR waste from consumers requires further development,” he adds.

Manufacturers in the PUR industry each use unique formulas to achieve specific material properties for their products.

Therefore, a number of challenges must be addressed before real savings in polyurethane recycling can be achieved:

- Waste sorting

- Logistics

- Sorting PUR by type

Depolymerization is therefore only a small part of the solution.

The AU researchers also tested the combination of acidolysis and hydrolysis on regenerated PUR foam and rigid PUR foam. And it works. But the paths to a circular economy are even longer here.

Rigid PUR foam is mainly used as an insulation material, but efforts to transform it into valuable raw materials are still in their infancy.

Currently, the researchers are testing the new technology on other polyurethane materials to see how they can be recycled. They are also investigating how the dicarboxylic acid, which is part of the process, can be reused. In addition, they will test the recycled materials to create new products to show that the technology can truly create a circular economy.

More information:

Thomas B. Bech et al, Chemical separation of polyurethane by acidolysis – combination of acidolysis and hydrolysis for the valorization of aromatic amines, Green chemistry (2024). DOI: 10.1039/D4GC00819G

Provided by Aarhus University

Quote: Researchers discover smarter way to recycle polyurethane (2024, August 16) retrieved August 16, 2024 from

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without written permission. The content is provided for informational purposes only.