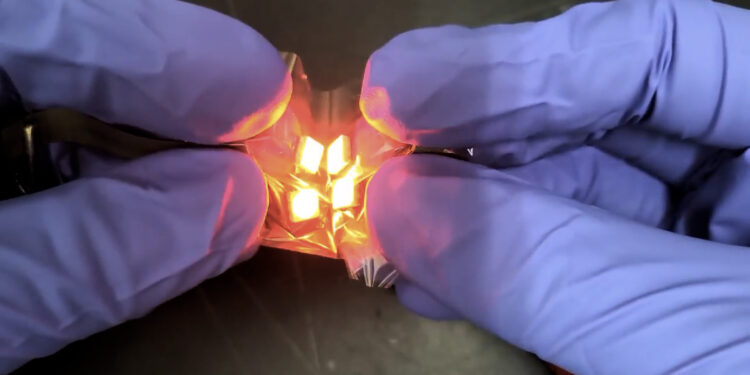

Researchers have developed a technique to print thin films of metal oxide at room temperature and have demonstrated the technique by printing metal oxides onto a polymer, creating highly flexible circuits. Credit: Minskik Kong

Researchers have demonstrated a technique for printing thin metal oxide films at room temperature and used the technique to create transparent, flexible circuits that are both robust and capable of operating at high temperatures.

The paper, “Ambient Printing of Native Oxides for Ultrathin Transparent Flexible Printed Circuits,” was published Aug. 15 in the journal Science.

“Creating metal oxides useful for electronics has traditionally required specialized equipment that is slow, expensive, and operates at high temperatures,” says Michael Dickey, co-corresponding author of a paper on the work and the Camille and Henry Dreyfus Professor of Chemical and Biomolecular Engineering at North Carolina State University.

“We wanted to develop a technique that would allow us to create and deposit thin films of metal oxide at room temperature, essentially printing metal oxide circuits.”

Metal oxides are an important material found in almost all electronic devices. Most metal oxides are electrically insulating (like glass). But some metal oxides are both conductive and transparent, and these oxides are especially important for your smartphone’s touchscreen or your computer’s display.

“In principle, metal oxide films should be easy to make,” Dickey says. “After all, they form naturally on the surface of almost every metal object in our homes: soda cans, stainless steel pots, and forks. Although these oxides are ubiquitous, their usefulness is limited because they cannot be removed from the metals on which they form.”

For this work, the researchers developed a new method to separate the metal oxide from a meniscus of liquid metal. If you fill a tube with liquid, a meniscus is the curved surface of the liquid that extends beyond the end of the tube.

The curvature of the meniscus is due to surface tension that prevents the liquid from flowing completely. In the case of liquid metals, the surface of the meniscus is covered with a thin layer of metal oxide that forms where the liquid metal meets the air.

“We fill the space between two glass slides with liquid metal so that a small meniscus extends beyond the ends of the slides,” Dickey explains.

“Think of the slides as a printer and the liquid metal as the ink. The liquid metal meniscus can then be brought into contact with a surface. The meniscus is coated with oxide on all sides, similar to the thin rubber that surrounds a water balloon.

“As we move the meniscus across the surface, the metal oxide on the front and back of the meniscus adheres to the surface and peels off, like a snail’s track. Meanwhile, the exposed liquid on the meniscus is constantly forming fresh oxide to enable continuous printing.”

The result is that the printer deposits a thin two-layer film of metal oxide with a thickness of about 4 nm.

“It’s important to note that even though we’re using a liquid, the metal oxide film that’s deposited on the substrate is solid and incredibly thin,” Dickey says. “The film adheres to the substrate, so it doesn’t stain or smear. That’s important for circuit printing.”

The researchers demonstrated this technique with several liquid metals and metal alloys, with each metal changing the composition of the metal oxide film. The researchers were also able to deposit a stack of thin layers by making multiple passes with the printer.

“One of the things that surprised us is that the printed films are transparent but have metallic properties,” Dickey says. “They are very conductive.”

“Because the films have a metallic character, the gold binds to the printed oxide, which is unusual: gold does not normally adhere to oxides,” says Unyong Jeong, co-corresponding author of a paper on the work and a professor of materials science and engineering at Pohang University of Science and Technology (POSTECH).

“When you introduce a small amount of gold into these thin films, the gold is essentially incorporated into the film. This helps prevent the conductive properties of the oxide from degrading over time.”

“We think these films are so conductive because the center of the two-layer thin film has very little oxygen, it’s more metallic and less oxide,” Jeong says.

“Without the presence of gold, more oxygen reaches the center of the laminated thin film over time, making the film electrically insulating. Adding gold to the thin film prevents oxidation of the central part of the film. The fact that this works so well is surprising because we use so little gold: the thin oxide film is still very transparent.”

In addition, the researchers found that the thin films retained their conductive properties at high temperatures. If the thin film is 4 nanometers thick, it retains its conductive properties up to nearly 600 degrees Celsius. If the thin film is 12 nanometers thick, it retains its conductive properties up to at least 800 degrees Celsius.

The researchers also demonstrated the usefulness of their technique by printing metal oxides onto a polymer, creating circuits that are highly flexible and robust enough to retain their integrity even after being bent 40,000 times.

“The films can also be transferred to other surfaces, such as foils, to create electronic components in unconventional locations,” Dickey says. “We are retaining the intellectual property of this technique and are open to collaborating with industrial partners to explore potential applications.”

More information:

Minskik Kong et al., Ambient printing of native oxides for ultra-thin transparent flexible printed circuits, Science (2024). DOI: 10.1126/science.adp3299. www.science.org/doi/10.1126/science.adp3299

Provided by North Carolina State University

Quote:New technique enables printing of thin-film metal-oxide circuits at room temperature (2024, August 15) retrieved August 15, 2024 from

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without written permission. The content is provided for informational purposes only.