After passing through the tag and hitting the surface of the object, the terahertz waves are reflected or backscattered to a receiver for authentication. Credit: Ruonan Han, Eunseok Lee et al.

A few years ago, MIT researchers invented a cryptographic identification tag several times smaller and significantly less expensive than traditional radio frequency (RFID) tags that are often placed on products to verify their authenticity.

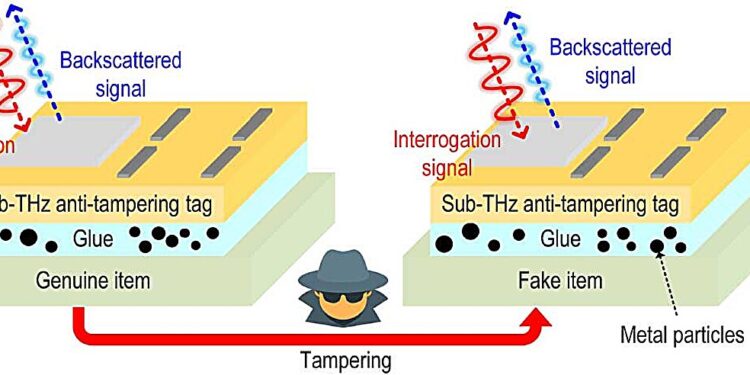

This small tag, which offers improved security over RFID, uses terahertz waves, which are smaller and propagate much faster than radio waves. But this terahertz tag shared a major security flaw with traditional RFID: a counterfeiter could peel the tag off a genuine item and attach it to a fake, and the authentication system would be none the wiser.

Researchers have now overcome this security flaw by harnessing terahertz waves to develop an anti-tampering identification tag that still offers the advantages of being small, cheap and secure.

They mix microscopic metal particles into the glue that sticks the label to an object, then use terahertz waves to detect the unique pattern these particles form on the object’s surface. Similar to a fingerprint, this random glue pattern is used to authenticate the item, says Eunseok Lee, a graduate student in electrical and computer engineering (EECS) and lead author of a paper on the anti-forgery label.

“These metal particles are essentially like mirrors for terahertz waves. If I spread a bunch of pieces of mirror on a surface and then illuminated it, depending on the orientation, size and “Where these mirrors are located, I would get a different reflection. But if you peel the chip off and reattach it, you destroy that pattern,” adds EECS associate professor Ruonan Han, who leads the Terahertz Integrated Electronics Group at electronics research laboratory.

The researchers produced a light-powered tamper-proof tag measuring approximately 4 square millimeters. They also demonstrated a machine learning model that can detect tampering by identifying fingerprints of similar glue patterns with over 99% accuracy.

Because the terahertz tag is very inexpensive to produce, it could be implemented throughout a massive supply chain. Its small size allows the tag to attach to objects too small for traditional RFID, such as certain medical devices.

The paper, which will be presented at the IEEE Semiconductor Circuits Conference, is a collaboration between Han’s group and the Energy Efficient Circuits and Systems group of Anantha P. Chandrakasan, head of innovation and MIT Strategy, Dean of the MIT School of Engineering. , and Professor Vannevar Bush of EECS. Co-authors include EECS graduate students Xibi Chen, Maitryi Ashok and Jaeyeon Won.

Prevent tampering

This research project was partly inspired by Han’s favorite car wash. The company stuck an RFID tag on its windshield to authenticate its car wash membership. For added security, the label was made from flimsy paper, so it would be destroyed if a disingenuous customer tried to peel it off and stick it to another windshield.

But this is not a very reliable way to prevent tampering. For example, someone could use a solution to dissolve the glue and safely remove the fragile label.

Rather than authenticating the label, a better security solution is to authenticate the item itself, Han says. To achieve this, the researchers targeted the glue at the interface between the label and the surface of the object.

Their tamper-resistant label contains a series of tiny slits that allow terahertz waves to pass through the label and strike the microscopic metal particles mixed in the glue.

Terahertz waves are small enough to detect particles, while larger radio waves would not have enough sensitivity to see them. Additionally, using terahertz waves with a wavelength of 1 millimeter allowed researchers to make a chip that does not need a larger off-chip antenna.

After passing through the tag and hitting the surface of the object, the terahertz waves are reflected or backscattered to a receiver for authentication. The way these waves are backscattered depends on the distribution of the metal particles reflecting them.

The researchers placed several slots on the chip so that the waves could hit different points on the object’s surface, capturing more information about the random distribution of particles.

“These responses are impossible to reproduce, as long as the glue interface is destroyed by a counterfeiter,” says Han.

A supplier would take an initial reading of the anti-tampering label once it was stuck on an item, then store that data in the cloud, to be used later for verification purposes.

AI for authentication

But when it came time to test the tamper-resistant label, Lee ran into a problem: It was very difficult and time-consuming to take measurements accurately enough to determine whether two glue designs matched.

He contacted a friend at MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL), and together they solved the problem using AI. They trained a machine learning model that could compare glue patterns and calculate their similarity with over 99% accuracy.

“One drawback is that we had a limited data sample for this demonstration, but we could improve the neural network in the future if a large number of these tags were deployed in a supply chain, which would give us a lot more sample data,” says Lee. .

The authentication system is also limited by the fact that terahertz waves experience high levels of loss during transmission, so the sensor can only be about 4 centimeters from the tag to get an accurate reading . This distance would not pose a problem for an application such as barcode scanning, but it would be too short for some potential uses, such as in an automated highway toll booth. Additionally, the angle between the sensor and the tag must be less than 10 degrees, otherwise the terahertz signal will degrade too much.

They plan to address these limitations in their future work and hope to inspire other researchers to be more optimistic about what can be accomplished with terahertz waves despite the many technical challenges, Han says.

“One thing we really want to show here is that the application of terahertz spectrum can go well beyond wireless broadband. In this case, you can use terahertz for identification, security and authentication. There are many possibilities.” he adds.

More information:

Ruonan Han et al, “A packaging-free anti-tampering tag using non-clonable sub-THz wave scattering at the chip-element interface,” IEEE Semiconductor Circuits Conference (2024). www.isscc.org/

Provided by the Massachusetts Institute of Technology

This story is republished courtesy of MIT News (web.mit.edu/newsoffice/), a popular site that covers news about MIT research, innovation and education.

Quote: This little tamper-proof ID tag can authenticate almost anything (February 18, 2024) retrieved February 18, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.