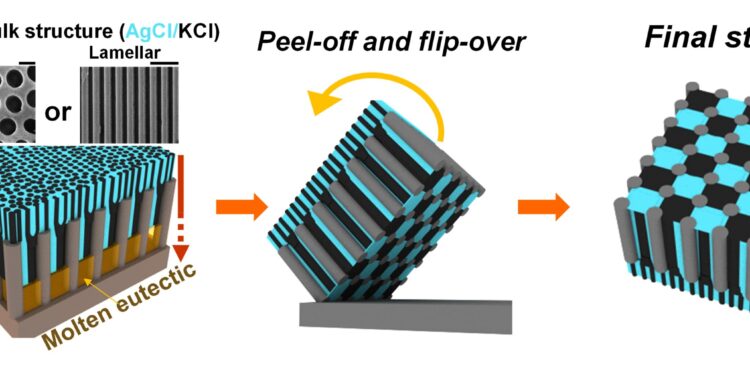

Schematic illustration of the model-driven eutectic solidification process. The liquid (gold) AgCl (cyan)-KCl (black) eutectic system solidifies through the pillar template. Credit: The Grainger College of Engineering at the University of Illinois at Urbana-Champaign

Model-driven self-assembled solidifying eutectic materials with miniature features demonstrate unique microstructures and patterns resulting from model-driven diffusion and thermal gradients. Although the template attempts to force the material to solidify in a regular pattern, when the template carries a lot of heat, it can also interfere with the solidification process and cause disorder in the long-range pattern.

Researchers at the University of Illinois Urbana-Champaign and the University of Michigan Ann Arbor have developed a template material that transports almost no heat and therefore stops heat transfer between the template material itself and the solidifying eutectic material. They achieved this by forming the model from a material with very low thermal conductivity, which ultimately resulted in highly organized self-assembled microstructures.

The results of this research were recently published in the journal Advanced materials.

“The main novelty of this research is that we carefully control the heat flow. By controlling the heat flow, the model becomes much better and smoother than before because we control more parameters. Previously, the model controlled the flow of heat. flow of atoms, but the heat flows were not controlled,” says Paul Braun, professor of materials science and engineering and director of the Materials Research Laboratory, who led this research with the researcher postdoctoral fellow Sung Bum Kang.

Eutectic materials are a homogeneous mixture whose melting point is lower than the melting point of either constituent. Common examples of eutectic systems include solder (a mixture of lead and tin) and mixtures of salt (sodium chloride) and water. When the eutectic mixtures are cooled from the liquid phase, they separate into two materials that form a pattern at the solidification front.

The material doesn’t just separate into two large layers. Instead, it forms structures including a multilayer (lamellar) structure, such as a layered cake, a rod-like structure, or even more complex structures. The resulting microstructure of the material, however, is only well ordered over short distances. Instabilities that arise during the self-assembly process lead to defects in the microstructure and affect the properties of the resulting solid material. For many applications, such as optics or mechanics, very good order over long distances is required.

The solidification process can be controlled by a template made of pillars that act as barriers to the movement of atoms and molecules. This forces the structure to form a more regular pattern as it solidifies. But the problem, Braun explains, is that the pillars carry a lot of heat and instead of having a flat, solidifying facade, the shape of the facade becomes complex. This leads to irregular patterns and long-term disorders.

“We figured out how to make the pillars so that they are very good insulators,” says Braun. “So all the heat only flows through the solidifying material. The model now only acts as a barrier to the flow of atoms, but almost no heat flows between the solidifying material and the model.”

The researchers explored model materials with lower thermal conductivities than the eutectic system and found that model materials with low thermal conductivity resulted in highly organized microstructures with long-range order. Specifically, they used porous silicon (essentially silicon foam) which is at least 100 times less thermally conductive than crystalline silicon. The low thermal conductivity of the template material minimizes heat flow in the “wrong” direction.

“The thermal conductivity of the template is a critical factor in determining the heat transfer rate during the solidification process,” Kang explains. “The porous silicon we used for the models has low thermal conductivity and leads to approximately 99% uniformity of the unit cells in the structure.”

In comparison, with crystalline silicon pillars with higher thermal conductivity, the expected pattern is only present in 50% of the unit cells.

“This means we can design eutectic materials with highly predictable and consistent properties. This level of control is crucial for applications where uniformity has a direct impact on performance,” says Kang.

More information:

Sung Bum Kang et al, Highly Ordered Eutectic Mesostructures via Model-Directed Solidification in Thermal Engineering Models, Advanced materials (2024). DOI: 10.1002/adma.202308720

Provided by the University of Illinois Grainger College of Engineering

Quote: Thermal Engineering Models for Highly Ordered Self-Assembled Materials (February 14, 2024) retrieved February 14, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.