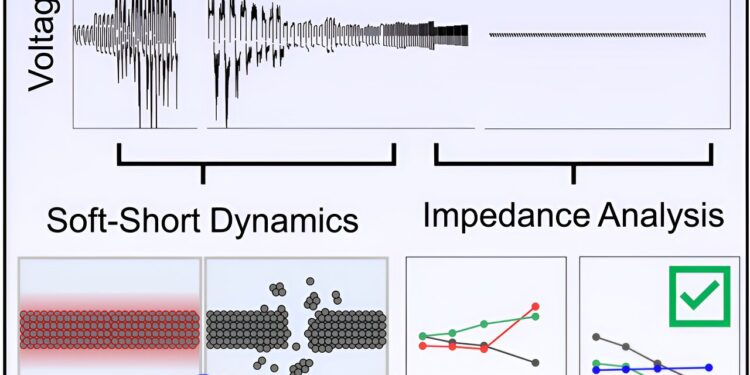

Graphical summary. Credit: Joule (2023). DOI: 10.1016/j.joule.2023.11.007

An Argonne team developing materials for solid-state batteries took an unexpected detour to study tiny short circuits called soft-shorts. Their knowledge will benefit battery researchers around the world.

Researchers at the U.S. Department of Energy’s (DOE) Argonne National Laboratory have shed important new light on what the first signs of battery failure look like. Their study, which appears in Joule and concerns a condition called soft-shorts, provides the research community with valuable knowledge and methods to design better electric vehicle (EV) batteries.

The Argonne team’s research focused on all-solid-state batteries with lithium metal anodes (negative electrodes). Many consider these devices to be the “Holy Grail” of battery technologies. For what? Because lithium metal can store a large amount of charge in a small space. This means it can enable much longer electric vehicle ranges than traditional lithium-ion batteries made with graphite anodes.

However, lithium metal presents operational challenges because it can be very reactive with liquid electrolytes in traditional batteries. Electrolytes are materials that move charged particles called ions between the two electrodes of a battery, converting stored energy into electricity.

When a normally operating battery discharges, ions flow from the anode through the electrolyte to the cathode (positive electrode). At the same time, electrons flow from the anode to an external device, such as a phone or electric vehicle motor, and then back to the cathode. The flow of electrons is what powers the device. When a battery is charging, these flows are reversed.

The use of lithium metal tends to disrupt this process. During charging, lithium filaments can grow out of the anode and enter the electrolyte. If these growths become large enough and extend to the cathode, they create a permanent “thread” between the electrodes. Eventually, all of the battery’s electrons flow through this wire from one electrode to the other without exiting the battery to power a device. This process also stops the flow of ions between the electrodes.

“This is called an internal short circuit,” said Michael Counihan, a postdoctoral fellow at Argonne and the team’s principal investigator. “The battery has failed and electrons are no longer powering your device.”

Installing lithium metal anodes in solid-state batteries (in other words, solid-state batteries) can potentially reduce filament-related issues while retaining the benefits of lithium.

An unexpected detour towards soft-shorts

The Argonne team was developing a new solid electrolyte for electric vehicle batteries and noticed some unusual behavior.

“When we used our batteries in the lab, we observed very small, very brief voltage fluctuations,” Counihan said. “We decided to take a closer look.”

The researchers charged and discharged their batteries repeatedly over hundreds of hours, measuring various electrical parameters like voltage. The team determined that the batteries were experiencing soft shorts, which are tiny, temporary short circuits.

With a soft-short, the lithium filaments grow from the anode to the cathode. But the amount of growth is less than in a permanent short circuit. While some electrons stay inside the battery, others can flow to an external device. The flow of ions between the electrodes can continue. All of these feeds can vary significantly.

The team worked with computer science experts at Argonne to develop models that predict the amount of ion and electron flow during short circuits. The models take into account factors such as the size of the lithium filaments and the properties of the electrolyte.

Soft short batteries can continue to operate for hours, days, or even weeks. But as the Argonne team discovered, the number of filaments typically increases over time and ultimately leads to battery failure.

“Soft shorts are the first step toward permanent battery failure,” Counihan said.

Dynamic behavior

The team’s closer examination revealed that soft shorts have very dynamic behavior. They often form, disappear and reform within microseconds or milliseconds.

“This is an important takeaway for battery researchers,” Counihan said. “With typical laboratory battery tests, researchers only measure voltage every minute or so. During that time, you could have missed the formation and death of thousands of soft shorts. They are like little ghosts that destroy your battery without you know it.”

The most common reason soft shorts disappear: heat. When electrons pass through the lithium filaments, heat is generated, similar to what can occur in the wires of household appliances. Heat can quickly melt filaments, especially if the surrounding electrolyte is thermally insulating.

Soft shorts can dissolve when the filaments react with certain electrolytes. Some of the solid electrolytes the Argonne team studied can cut small filaments before they reach the cathode and cause an internal short circuit.

Helping the research community

During its extensive examination of soft shorts, the Argonne team developed and demonstrated several new methods for detecting and analyzing the phenomenon. For example, one method quantifies the contribution of soft shorts to a battery’s resistance to current flow. Since different battery components can contribute to this resistance, isolating the contribution of soft shorts can help researchers better assess the health of their batteries.

The study includes a list of nearly 20 detection and analysis techniques. About a third of these methods come from the team’s recent research. The study authors gathered the other methods from informal, unpublished knowledge from the research community.

“We realized that there is no article in the literature that uses more than two of these techniques,” Counihan said. “To make the list more useful to researchers, we have included information on the pros and cons of each method. Since soft shorts are so dynamic, it is good that researchers have many tools to better understand the impacts soft shorts.”

The team wanted to provide researchers around the world with information about soft shorts to inform their work. For example, the techniques described in the article can help advance the design of hard solid electrolytes that inhibit the growth of lithium filaments.

“When researchers understand the dynamics of soft shorts in their batteries, they are better equipped to refine their materials to avoid these failure pathways,” Counihan said.

More information:

Michael J. Counihan et al, The Phantom Threat of Dynamic Soft Shorts in Solid-State Battery Research, Joule (2023). DOI: 10.1016/j.joule.2023.11.007

Provided by Argonne National Laboratory

Quote: Getting to know the ‘ghost’ inside batteries: an in-depth look at tiny shorts (February 7, 2024) retrieved February 7, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.