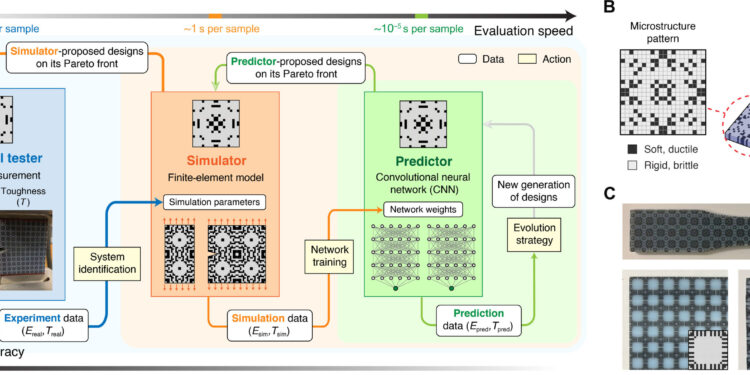

Diagram of the process. Credit: Scientists progress (2024). DOI: 10.1126/sciadv.adk4284

Using 3D printing, researchers from the University of Australia and the Massachusetts Institute of Technology have developed a new approach to achieving an optimal combination of stiffness and toughness in microstructured composites.

The study was published in Scientists progress.

By integrating physical experiments, numerical simulations, and machine learning to address these two challenges, their method provides a model for computational design in research areas beyond solid mechanics, such as polymer chemistry, fluid dynamics, meteorology and robotics.

“Stiffness and strength are often mutually exclusive,” said Wan Shou, assistant professor of mechanical engineering at the University of Alberta and corresponding author of the paper. “To be rigid, a material must be strong to resist deformation. To be strong, it must be sufficiently ductile, that is, capable of deforming without losing rigidity, to tolerate long cracks and absorb more of energy before fracturing.

An optimal combination of stiffness and toughness is a kind of holy grail in engineering materials design. In response to applied force, materials must have the ability to resist deformation (stiffness) without cracking rapidly (toughness). In other words, bend, don’t break.

This performance is particularly important in macro materials such as steel for buildings and bridges. However, the systematic discovery of microstructured composites with optimal stiffness-toughness tradeoffs has been hampered by discrepancies between simulation and reality.

Recent advances in additive manufacturing and computational methods have enabled more efficient exploration leading to a design that optimally combines these qualities. So far, no systematic discovery of microstructured composites with optimal stiffness-toughness trade-offs has been demonstrated.

The researchers used three raters:

- A mechanical tester that performs physical measurements,

- A simulator based on the finite element method that performs virtual mechanical tests of moderate complexity and

- A convolutional neural network-based predictor that performs machine learning inference.

The mechanical tester operates slowly due to labor-intensive sample manufacturing and testing, but this provides accurate and reliable performance values for a microstructure design. On the opposite end of the spectrum, the predictor works extremely quickly but gives relatively inaccurate results. Between these, the simulator runs reasonably quickly, given its moderate complexity, and provides intermediate accuracy.

In this work, accuracy and speed are taken into account. More importantly, the researchers’ framework establishes a new paradigm for overcoming the often-seen gaps between theoretical models and practical results.

More information:

Beichen Li et al, Computational discovery of microstructured composites with optimal stiffness-toughness trade-offs, Scientists progress (2024). DOI: 10.1126/sciadv.adk4284

Provided by University of Arkansas

Quote: Researchers determine the optimal compromise between rigidity and resistance (February 6, 2024) retrieved February 6, 2024 from

This document is subject to copyright. Apart from fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.